ABB DCS400 series thyristor DC drive power converter

Core advantages: Combining the ease of use of analog transmission with the advantages of digital transmission, compact size, easy installation, integrated exciter (including fuses and reactors), using IGBT excitation technology without the need for voltage adaptation transformers, supporting guided debugging and application macro configuration, improving efficiency and reducing errors.

ABB DCS400 series thyristor DC drive power converter

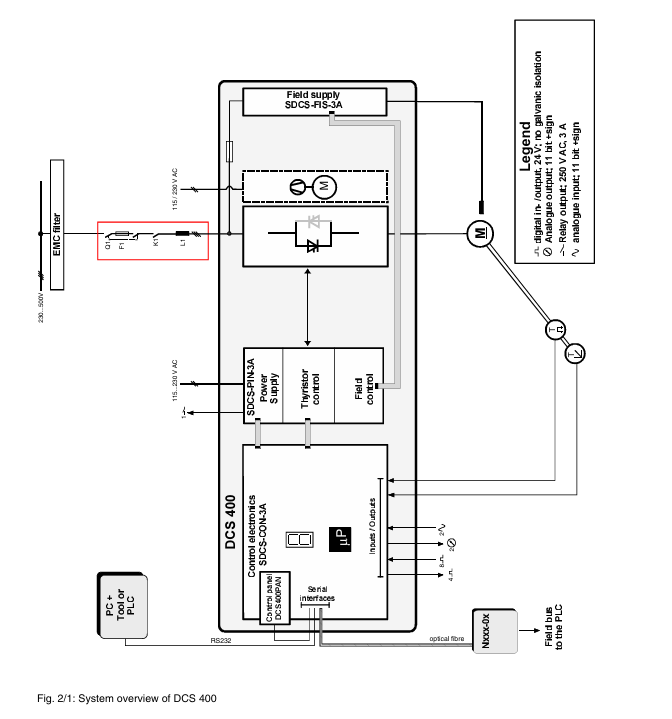

Product overview

Positioning and Application: A new generation compact DC drive device with a rated current of 20-1000A and a power of 9-522kW, suitable for 230-500V AC power supply and widely used in industrial machinery drive scenarios.

Core advantages: Combining the ease of use of analog transmission with the advantages of digital transmission, compact size, easy installation, integrated exciter (including fuses and reactors), using IGBT excitation technology without the need for voltage adaptation transformers, supporting guided debugging and application macro configuration, improving efficiency and reducing errors.

Technical Parameter

Power and Environment:

Three phase power supply 230-500V, allowable ± 10% deviation, frequency 50/60Hz; electronic power supply 115-230V, allowable -15%/+10% deviation.

Working temperature: rated current+5~+40 ℃, power module+40~+55 ℃; Storage temperature -40~+55 ℃, transportation temperature -40~+70 ℃; Relative humidity of 5-95% without condensation.

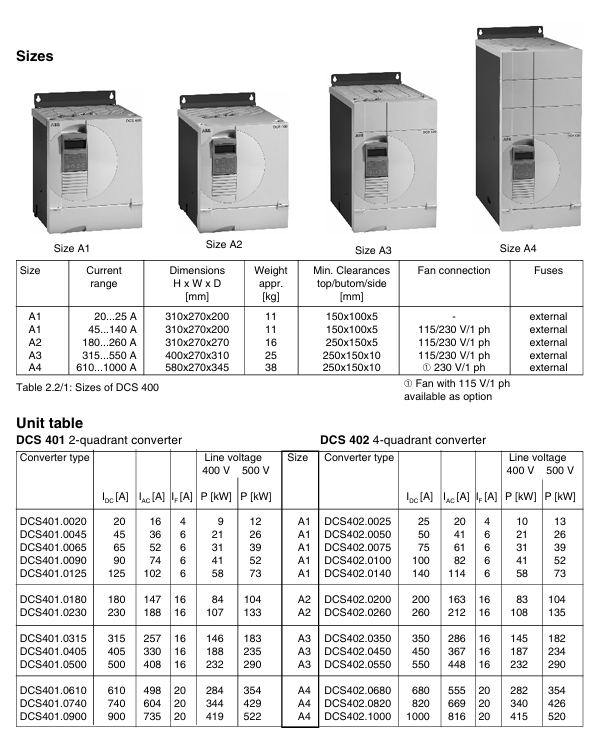

Structure and size:

Divided into four sizes A1-A4, weighing 11-38kg, with a protection level of IP00 (power module), ventilation space needs to be reserved for installation (such as 150mm and 100mm above and below A1).

Overload capacity: Depending on the load cycle (DC I-DC IV), it supports 150% -200% overload, with a duration ranging from 10 to 120 seconds.

Cooling and power consumption: Some models require fan cooling (such as A1's 45-140A with 2 × CN2B2 fans), and power loss varies with load (such as A1's 20A model losing 49W at 100% load).

FUNCTION

Application macros: preset 8 macro configurations, define digital I/O, reference source and other functions. For example, Macro 1 (standard mode) supports analog speed reference and external torque limitation, while Macro 8 (torque control) uses analog quantity as torque reference.

Control function:

Speed control: supports speed generator, encoder, back electromotive force feedback, with functions such as S-shaped slope, 2 sets of acceleration and deceleration slopes, and automatic demagnetization.

Current/torque control: including current limit, torque limit, I ² t motor protection, supporting switching of second current limit.

Self optimization: It can automatically optimize parameters such as armature current, excitation current, speed controller, etc.

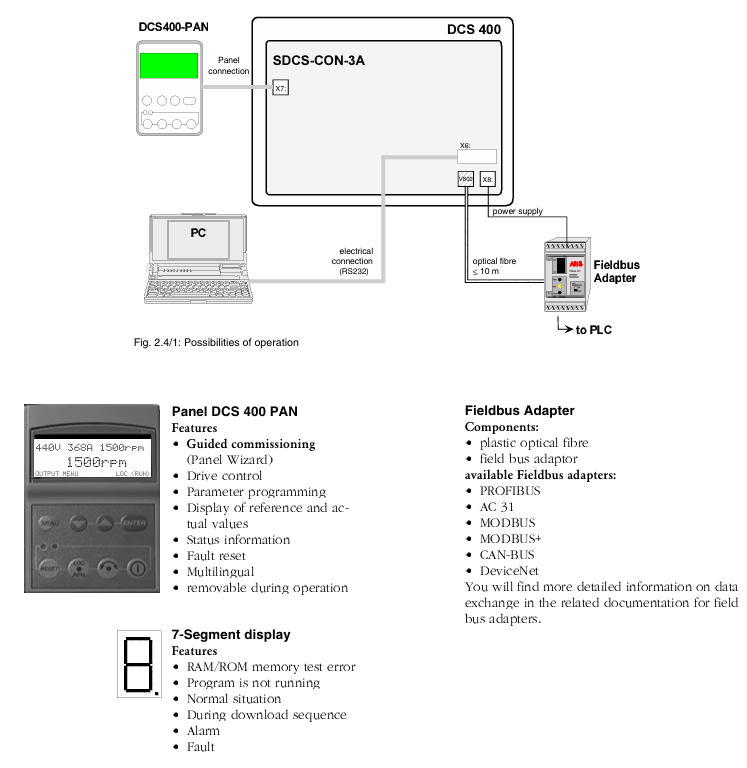

Communication and Interface: Supports RS232, Panel Port, and various fieldbuses (PROFIBUS, MODBUS, etc.) to transmit control commands, reference values, and status information through datasets.

Installation and Connection

Installation steps: Drill holes (92 × 92mm) according to DIN 43700 standard, and fasten the equipment with clamping claw screws to ensure ventilation space.

Wiring requirements:

The power and signal terminals are connected by plug-in screws, with a maximum wire cross-section of 1.5mm ² (2.5mm ² for relays) and a maximum relay output of 250V AC/1A.

Grounding and shielding: The protective grounding needs to be connected, and the shielding layer of the signal cable is fixed on the shielding terminal board.

Operation and Debugging

Control panel: parameter settings, fault diagnosis, local operations are implemented through the DCS400 PAN panel, supporting multilingual display and guided debugging.

Debugging process: Use the "Commissioning" function to configure motor parameters (rated current, voltage, speed, etc.) step by step, select control mode, and perform self optimization to ensure system matching.

Troubleshooting

Faults and alarms: Detailed list of fault codes (such as F07 for converter overheating, F09 for main power undervoltage) and alarm codes (such as A02 for main power low voltage), including possible causes and troubleshooting methods.

Diagnostic function: View detailed fault information through the "Diagnosis" parameter, support fault records (up to 16), and facilitate problem tracing.

Security and Authentication

Compliant with CE, UL 508C, CSA C22.2 and other standards, following the Machinery Directive, Low Voltage Directive and EMC Directive, installation must comply with safety regulations (such as power-off operation and correct grounding).

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands