HARTING DIN 41612 connector

HARTING DIN 41612 connector

DIN 41612 connector is a universal connector that complies with German industrial standards. It is mainly produced by brands such as HARTING and widely used in industrial automation and measurement technology fields. It supports board to board and cable to board connections, and has both signal transmission and power supply functions. With high robustness, versatility, and flexible scalability as its core advantages, it can adapt to diverse industrial needs from low current signals to high power (40A).

Product Classification and Core Features

DIN 41612 connectors are mainly divided into signal type (DIN Signal), power type (DIN Power), and expansion type har bus according to their functions and current carrying capacity ® 64 major categories, each with distinct characteristics:

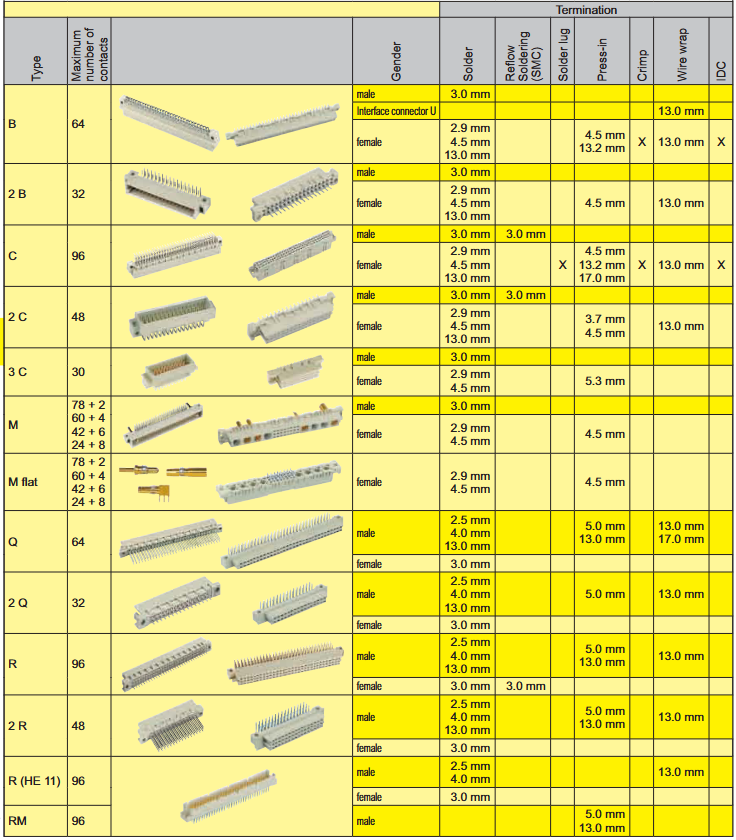

1. Signal type (DIN Signal)

Core positioning: Low current signal transmission (maximum 2A per single contact), suitable for low-power scenarios such as data and control signals.

Key parameters:

Contact quantity: 16-160 cores, supporting high-density layout (contact spacing 2.54mm).

Electrical performance: Test voltage 1kV (r.m.s), contact resistance ≤ 15m Ω (welding/winding connection), ≤ 20m Ω (crimping connection), insulation resistance ≥ 10 ¹² Ω.

Environmental adaptability: Working temperature -40~+105 ℃ (crimping type), -55~+125 ℃ (conventional type), reflow soldering (SMC process) can withstand 240 ℃/15s, meeting industrial high and low temperature environments.

Typical models: covering B, 2B, Q, 2Q, R, 2R and other series, such as R series (96 cores) and Q series (64 cores), supporting various PCB termination methods such as direct insertion (THT) and surface mount (SMT).

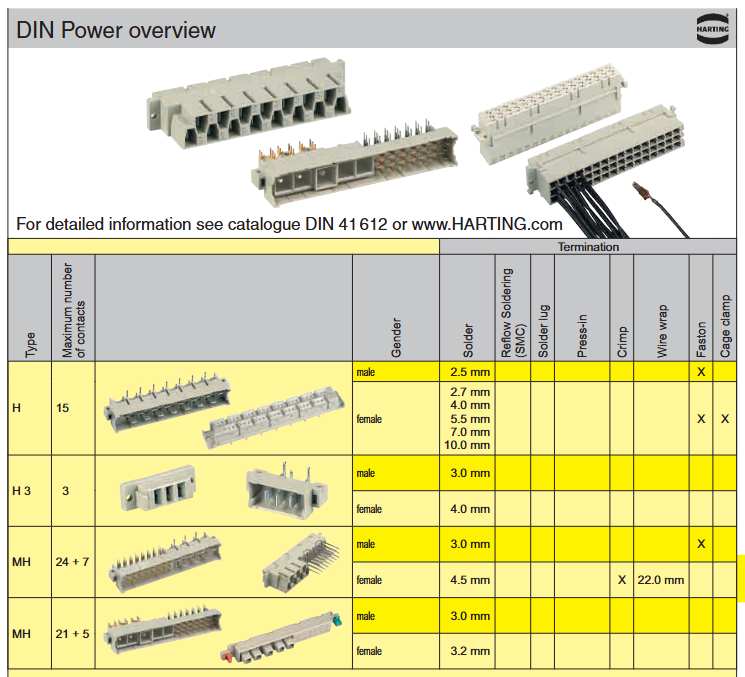

2. Power type (DIN Power)

Core positioning: High current power transmission (maximum 40A per single contact), suitable for high-power scenarios such as motor drive and power distribution.

Key parameters:

Contact quantity: 3-48 cores, optional contact spacing of 2.54mm (low power) or 5.08mm (high power).

Current and voltage: Type D/E/F series up to 6A, Type H/H3 series up to 15A; test voltage 1.55kV (conventional type), 2.5-3.1kV (H/H3 series), meeting high voltage insulation requirements.

Environment and Materials: The working temperature is the same as the signal type, and the shell is made of glass fiber reinforced thermoplastic resin (UL 94-V0 flame retardant). The contacts are made of copper alloy, and the surface can be coated with hard silver or gold to improve conductivity and corrosion resistance.

Typical models: D (32 core), E (48 core), F (48 core), H (high-power) series, supporting crimping (Crimp), welding (Solder), cage clamp and other termination methods, suitable for different cable types.

3. Extended type (har bus) ® 64)

Core positioning: A high-density expansion version of signal type connectors, compatible with traditional 3-row C-type DIN 41612 connectors, achieving "backward compatibility+performance upgrade".

Key features:

Contact configuration: 5 rows of 160 cores (adding 2 rows on the basis of 3 rows of 96 cores), contact spacing of 2.54mm, supporting any combination and docking with 3 rows of C-type connectors (such as 5 rows of male connectors matched with 3 rows of female connectors), adapting to the phased upgrade requirements of the system.

Electrical performance: Contact resistance ≤ 20m Ω (a/b/c rows), ≤ 30m Ω (z/d rows), test voltage 1kV, compatible with existing bus systems (such as 3 rows of C96 cores), and can expand the number of contacts without overall reconstruction.

Mechanical and installation characteristics

1. Structural design

Shell types: available in plastic, metalized plastic, and all metal, suitable for different protection and electromagnetic compatibility (EMC) requirements:

Plastic casing: Basic protection (IP20), suitable for dry and non strong electromagnetic interference control cabinet environments.

Metalized/all metal casing: enhances EMC shielding performance, suitable for industrial strong interference scenarios (such as near motors and high-voltage equipment).

Locking and fixing: Supports multiple installation methods, including screw fixing, locking lever quick locking, and snap in clips. The snap in clip can be integrated with the PCB through welding process to reduce screw/rivet costs and enhance mechanical protection during insertion and removal.

2. Termination and adaptation methods

DIN 41612 connectors support full field termination requirements, covering different installation processes and cable types:

PCB termination: Direct insertion (THT), surface mount (SMT), press in, suitable for single/double-sided PCB boards (thickness 1.6~4.0mm).

Cable termination: insulation displacement (IDC), crimping (Crimp), wire wrap, cage clamp. IDC is suitable for multi-core flat cables, crimping is suitable for flexible wires, and cage clamp supports fast wiring and prevents loosening.

Compatibility: Some models (such as har bus) ® 64) Support "mixed docking", for example, 5 rows of male and 3 rows of female connectors can be directly mated, so there is no need to replace all connectors when upgrading old systems, reducing renovation costs.

Application scenarios and adaptation areas

DIN 41612 connectors are widely used in core industrial automation scenarios due to their versatility and diversity

1. Industrial automation equipment

Board to board connection: Internal PCB interconnection of servo drives, PLC modules, and industrial computers (IPC), such as signal transmission (DIN Signal) between controllers and I/O modules, and power distribution (DIN Power) between power modules and motherboards.

Cable to board connection: signal access from sensors (such as proximity switches, encoders) to control cabinets, power connection from motor power cables to drivers, supporting shielded cables (reducing EMC interference) and unshielded cables (low-cost scenarios).

2. Measurement and testing equipment

Adapt to devices such as data collectors, oscilloscopes, signal generators, etc., using high-density signal type connectors (such as har bus) ® 64 and 160 cores) to achieve multi-channel data synchronous transmission, with a test voltage of 1kV to meet the insulation requirements for high-precision measurement.

3. Special environmental applications

Metal shell models (such as D20 metal) can be used in scenarios with strong electromagnetic interference (such as near frequency converters), with an IP20 protection level suitable for installation inside control cabinets; Partial power type models (Type H) have passed high-voltage testing (3.1kV) and can be used for power distribution of high-voltage equipment.

Key information for selection and ordering

1. Selection dimension

Function matching: DIN Signal (such as R series 96 core) is selected for signal transmission, DIN Power (such as H series 15A) is selected for power transmission, and har bus is selected for high-density expansion ® 64.

Electrical parameters: Determine the model based on current (2A/6A/15A), voltage (1kV/1.55kV/3.1kV), and number of contacts. For example, choose Type H (15A/3.1kV) for motor drive and Type R (2A/1kV) for sensor signal.

Installation process: THT/SMT is selected for PCB termination, IDC/crimping is selected for cable termination, metal shell is selected for strong EMC scenarios, and locking rod/buckle fixation is selected for quick installation.

2. Typical accessories and supplementary products

Shell accessories: Open hood, junction element, locking lever, used to enhance protection and installation stability.

Terminal block: 128015-08 and other external terminal blocks, suitable for wiring arrangement when connecting cables to boards.

Tools and consumables: crimping tools, welding auxiliary fixtures, shielded cables, HARTING provides a complete set of adaptation tools to ensure installation consistency.

Core advantages and user value

Strong universality: Compliant with both DIN 41612 and IEC 60603-2 standards, products from different brands (such as HARTING and Disai) can be compatible with each other, reducing supply chain risks.

Cost optimization: supports phased upgrades (such as har bus) ® 64 compatible with old 3-row connectors, reducing system reconstruction costs; Snap on fixation replaces screws, reducing installation time.

High reliability: flame retardant material (UL 94-V0), high and low temperature resistant design, low contact resistance, reducing the probability of failure in industrial scenarios, and improving equipment MTBF (mean time between failures).

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands