Emerson DeltaV ™ M-series Traditional I/O

Reduce capital equipment costs: The entire system is designed to be modular and supports live installation (refer to specific area installation guidelines). I/O interface carriers and interfaces can be flexibly added or removed according to 4/8/16/32 channel groups to avoid overinvestment; The compact design of I/O components allows for installation in on-site junction boxes, reducing the footprint of control room equipment; On site installation reduces long-distance wiring of multi-core cables, integrated design eliminates grouping panels, built-in series fuses and bus power supply reduce external accessory costs.

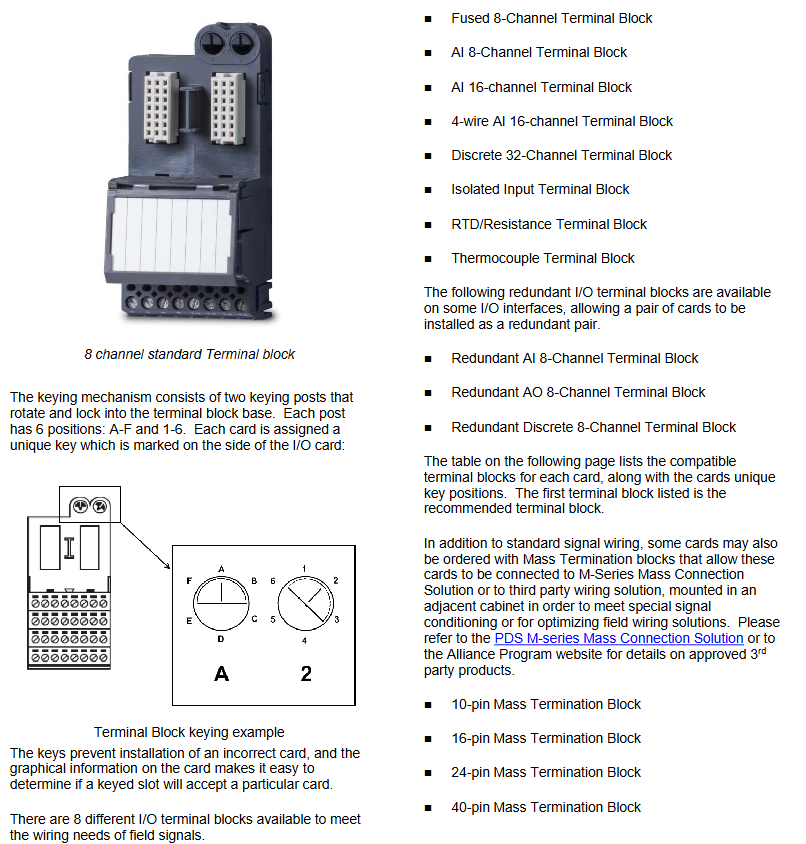

Shortening installation time and cost: With its plug and play feature, I/O components can be directly inserted into the carrier, supporting the installation of the carrier to reserve expansion space before installing the I/O interface; Staged installation is efficient, and once the carrier is in place, on-site equipment wiring can begin without waiting for I/O card installation; The I/O interface and terminal block are equipped with function keys to ensure the correct matching of the card and terminal block, avoid accidental installation, and simplify the installation and replacement process.

Emerson DeltaV ™ M-series Traditional I/O

Core positioning and core advantages

The DeltaV M series traditional I/O is a modular process control system I/O subsystem that focuses on "on-site installation, low-cost deployment, and high availability". It is suitable for industrial scenarios that require flexible expansion and reliable operation. The core advantages can be summarized as four key features:

Reduce capital equipment costs: The entire system is designed to be modular and supports live installation (refer to specific area installation guidelines). I/O interface carriers and interfaces can be flexibly added or removed according to 4/8/16/32 channel groups to avoid overinvestment; The compact design of I/O components allows for installation in on-site junction boxes, reducing the footprint of control room equipment; On site installation reduces long-distance wiring of multi-core cables, integrated design eliminates grouping panels, built-in series fuses and bus power supply reduce external accessory costs.

Shortening installation time and cost: With its plug and play feature, I/O components can be directly inserted into the carrier, supporting the installation of the carrier to reserve expansion space before installing the I/O interface; Staged installation is efficient, and once the carrier is in place, on-site equipment wiring can begin without waiting for I/O card installation; The I/O interface and terminal block are equipped with function keys to ensure the correct matching of the card and terminal block, avoid accidental installation, and simplify the installation and replacement process.

Enhance productivity: Support real-time addition of devices online, without interrupting the process when adding I/O interfaces. DeltaV resource manager automatically recognizes and allocates basic configurations to ensure production continuity.

Improve process availability: Both traditional I/O and HART I/O cards support 1:1 redundancy. Redundant and non redundant use the same series of second-generation I/O cards, which can reuse existing I/O and spare parts investments. Redundant channels do not require additional configuration, and the wiring of redundant terminal blocks is consistent with that of single terminal blocks, without the need for additional wiring; The system automatically recognizes redundant I/O, and redundant card pairs are displayed as single cards in the system tool, simplifying configuration; When the main I/O card fails, it automatically switches to the backup card without manual intervention, and the operator interface will clearly indicate the switching status.

Core components and functional details of the product

(1) Core hardware components

The I/O interface carrier is mounted on a DIN rail surface and supports modular expansion of all I/O related components. It can be installed live (in specific scenarios), providing a foundation for the installation of I/O cards and terminal blocks

Power supply AC to 24V DC large capacity power supply, integrated design for on-site equipment power supply, reducing external power configuration requirements

The I/O interface consists of an I/O card and an I/O terminal block. The I/O card supports multiple signal types, and the terminal block is adapted to different wiring requirements. The two are matched through function keys to prevent accidental installation

The I/O card features a unified design for analog (AI/AO) and discrete (DI/DO) series, making it easy to insert into the carrier; Equipped with power supply and internal fault indicator light, the 8-channel card is equipped with channel status LED; Compliant with ISA G3 anti-corrosion standards (high-quality components+conformal coating)

The I/O terminal block is installed on the carrier and supports pre wiring of multiple types to adapt to different I/O cards. Some include fuses, while redundant terminal blocks support installation of redundant card pairs. Some can be paired with large-scale terminal blocks to connect third-party wiring solutions

(2) I/O card types and key functions

1. Support redundant and non redundant I/O cards (core models)

AI card 8 4-20mA HART per channel optical isolation (1500VDC test), accuracy 0.1% range, 16 bit resolution, supports HART transparent transmission/variable/device status reporting

AO card 8 4-20mA HART per channel optical isolation (1500VDC test), accuracy 0.25% range, 12 bit resolution, output compliance 20mA@24VDC (700 Ω load)

DI card 8 24VDC dry contacts with optical isolation per channel (1500VDC test), conducting detection>2.2mA, turning off detection<1mA, input impedance of approximately 5K Ω

DO card 8 24VDC high side optical isolation per channel (1500VDC test), output range 2-60VDC, rated 1.0A, supports discrete/instantaneous/continuous pulse output modes

2. Only supports non redundant I/O cards (supplementary models)

Analog input AI card 16 4-20mA HART accuracy 0.2% range, no optional fuse

Isolation AI card with 4 thermocouples/RTDs/mV/V high isolation level (channel system 5000VDC test), supporting independent configuration of multiple signal types

RTD card 8 Pt100/Pt200 with 100 μ A excitation current, 16 bit resolution, open circuit detection for 1 second

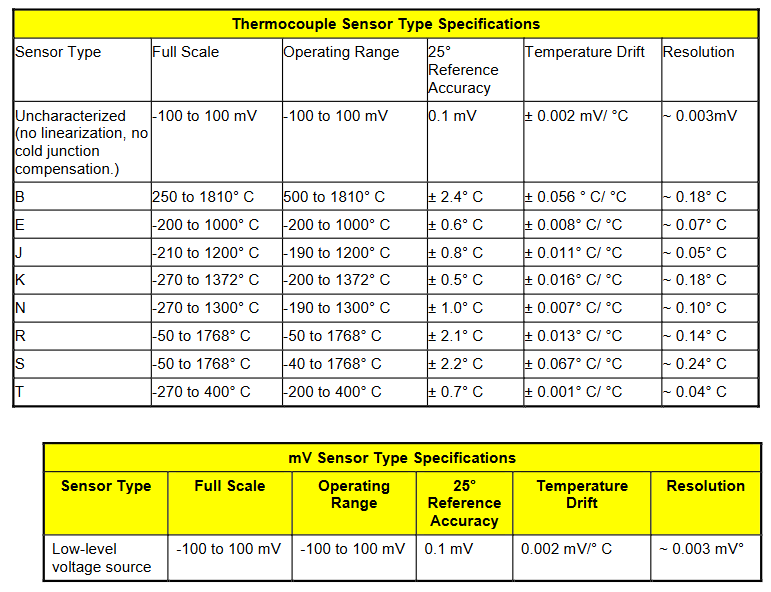

Thermocouples/mV card with 8 types of thermocouples (B/E/J, etc.)/mV support for local/remote cold junction compensation, 16 bit resolution

Discrete input high-density DI card 32 24VDC dry contact shared common return line, 32 screw terminal block, conductivity detection>2mA

Isolation DI card 8 24VDC inter channel optical isolation (1500VDC test), conductivity detection>10VDC

Sequence of Events (SOE) DI card 16 24VDC dry contact channel scan rate 0.25ms, timestamp accuracy ± 0.25ms (single card)/± 1ms (single controller)

AC DI card 8 120VAC (dry contact/isolation) isolation level 250VAC, suitable for AC signal detection

Discrete output high-density DO card 32 24VDC high side shared common return line, 32 screw terminal blocks, 100mA per channel

Isolation DO card 8 24VDC/120-230VAC inter channel optical isolation, supports multiple output modes, AC model rated 1.0A/channel

(3) Redundant switching mechanism

Switching triggering scenarios: hardware failure of the main card, communication failure between the main card and the controller, on-site wiring failure, and manual triggering through the diagnostic resource manager.

Switching performance: Redundant I/O card switching is completed within 2 scanning cycles of the I/O bus; The 'first on, then off' contact ensures continuous power supply for digital field devices, and the analog output signal is briefly driven by the dual card during switching (<5ms) without process disturbance.

Fault alarm and recording: Hardware alarms automatically report integrity errors between the primary and backup cards, switch events are recorded in the system event log, control module level timestamps record log events and alarms, and SOE cards can provide higher resolution (± 0.25ms/card) event recording.

Convenience of maintenance: In safe areas, faulty cards can be replaced with electricity, while in hazardous areas, specific installation procedures must be followed; The new backup card is automatically debugged and activated by the system.

Hardware specifications and compatibility

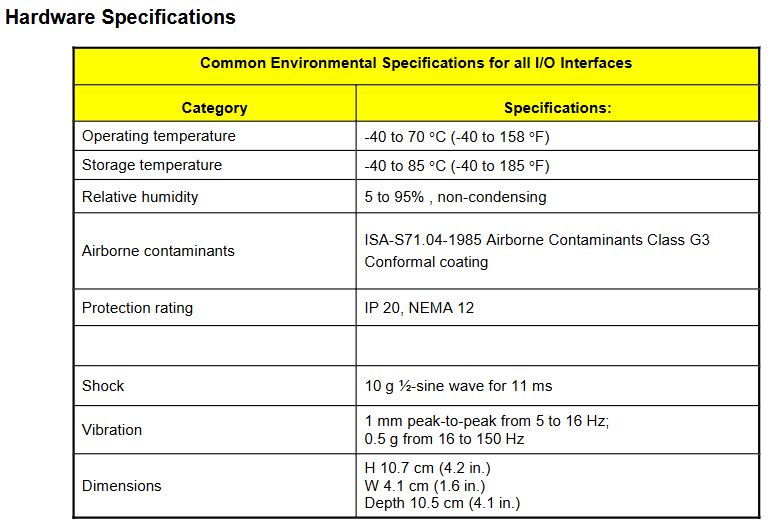

(1) General Environment and Dimensional Specifications

Environmental specifications: Operating temperature: -40~70 ° C (-40~158 ° F); Storage temperature: -40~85 ° C (-40~185 ° F); Relative humidity: 5%~95% (without condensation); Pollutant level: ISA-S71.04-1985 G3 level (with conformal coating); Protection level: IP20, NEMA 12; Impact resistance: 10g half sine wave (continuous for 11ms); Vibration: 5-16Hz (1mm peak to peak), 16-150Hz (0.5g)

Dimensions: Height 10.7cm (4.2 inches), Width 4.1cm (1.6 inches), Depth 10.5cm (4.1 inches)

(2) System compatibility and certification

Compatibility limitation: M-series traditional I/O cards are physically incompatible with S-series controller carriers and are only compatible with M-series related hardware.

Core certification:

Security certification: CE(EMC EN 61326-3-1:2006、LVD 2006/95/EC)、FM(3600/3611/3810、ANSI/ISA 60079 Series), CSA (C22.2 series, CAN/CSA-E60079 series), ATEX (94/9/EC, EN60079 series), IECEx (IEC60079 series).

Hazardous Area Certification: FM/CSA Class I Division 2 (Groups A-D, T4); ATEX/IECEx Zone 2(Ex nA/nL/ic/nC IIC T4 Gc); Classification certification (IACS E10:2006, DNV 2.4:2006, etc.); Russia GOST Zone 2 certification (POCC US. ГБ 05. B03564), planning to apply for EAC hazardous area certification (Russia, Belarus, Kazakhstan).

Ordering information and spare parts

(1) Core Product Order List (Some Key Models)

Analog input card terminal block 8-channel 4-20mA HART card standard terminal block VE4003S2B1

8-channel 4-20mA HART card redundant terminal block VE4033S2B1

16 channel 4-20mA HART card standard terminal block VE4003S2B6

8-channel thermocouple/mV card cold end compensation terminal block VE4003S5B1

8-channel RTD card terminal block VE4003S6B1

Analog output card terminal block 8-channel 4-20mA HART card standard terminal block VE4005S2B1

8-channel 4-20mA HART card redundant terminal block VE4035S2B1

Discrete input card terminal block 8-channel 24VDC dry contact DI card standard terminal block VE4001S2T2B1

32 channel 24VDC dry contact DI card standard terminal block VE4001S2T2B4

16 channel SOE DI card 32 channel terminal block VE4001S5T2B4

Discrete output card terminal block 8-channel 24VDC isolated DO card standard terminal block VE4002S1T1B1

32 channel 24VDC high side DO card standard terminal block VE4002S1T2B5

8-channel 120-230VAC high side DO card standard terminal block VE4002S2T2B1

(2) Spare parts information

250V 2A fuses (20 per box) KJ4010X1-BC1 compatible with all fused terminal blocks

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands