How to order Emerson DeltaV Ethernet I/O Card (EIOC)?

Direct connection to Ethernet device network: No intermediate gateway is required, and external Ethernet devices can be directly connected through Modbus TCP, EtherNet/IP, IEC 61850 MMS, OPC UA client, and EtherNet/IP control tag integration protocol. It supports device monitoring and control, operates independently of DeltaV controller, and reduces system complexity.

How to order Emerson DeltaV Ethernet I/O Card (EIOC)?

Core positioning and core advantages

DeltaV Ethernet I/O Card (EIOC) is an embedded data server designed specifically for DeltaV systems to access external Ethernet device networks. It supports multiple industrial Ethernet protocols and can directly communicate with third-party Ethernet devices (such as PLCs, motor control centers, intelligent electronic devices, etc.) to achieve data acquisition and device control. Its core advantages can be summarized as seven key features:

Direct connection to Ethernet device network: No intermediate gateway is required, and external Ethernet devices can be directly connected through Modbus TCP, EtherNet/IP, IEC 61850 MMS, OPC UA client, and EtherNet/IP control tag integration protocol. It supports device monitoring and control, operates independently of DeltaV controller, and reduces system complexity.

High capacity and scalability: The license mode based on the number of device connections adapts to different needs, and the data access capability varies with the protocol: under the Modbus TCP/Ethernet/IP/IEC 61850 MMS protocol, up to 256 devices and 32000 signals can be accessed; Under the OPC UA client protocol, up to 64 servers and 30000 real-time signals can be accessed; Under the EtherNet/IP control tag integration protocol, up to 256 devices and 2000 tags (10 signals per tag) can be connected to meet the requirements of large-scale industrial scenarios.

Complete monitoring and control functions: The accessed data can be processed in the built-in control module of EIOC, supporting alarm generation, historical data collection, and operator interface display. The functions are consistent with traditional DeltaV controllers; Supports discrete control and limited PID control function blocks, without the need to allocate them to DeltaV controllers, and can directly control Ethernet devices such as motors, switchgear, and frequency converters.

Powerful processing capability: A single EIOC can run up to 2000 control modules, and the system supports up to 60 EIOCs directly connected to the DeltaV control network, flexibly achieving network isolation and adapting to complex factory network architectures.

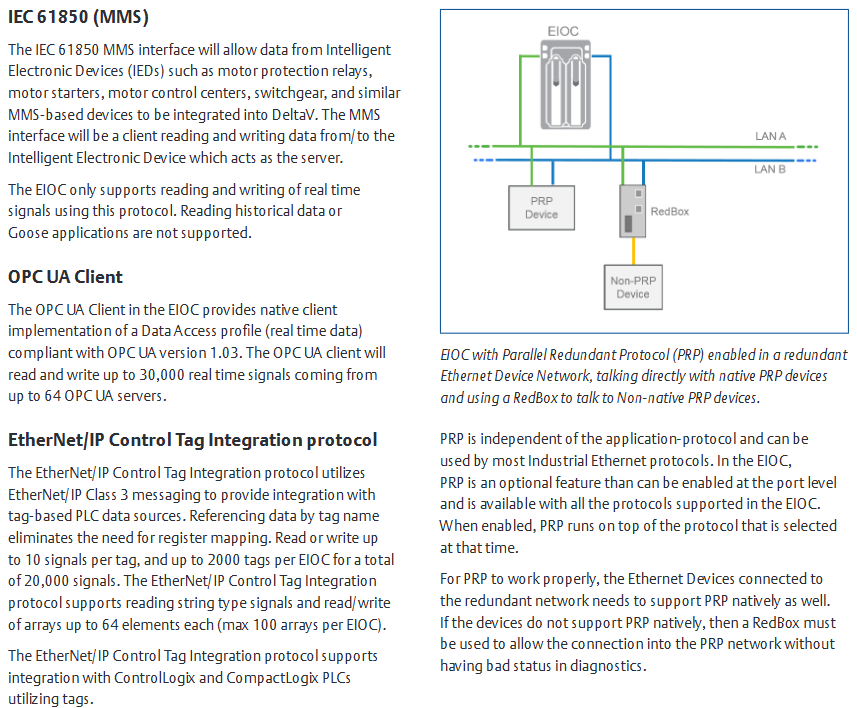

Flexible network configuration: Users can manually configure the IP address of Ethernet device networks to adapt to various factory network solutions; The simplex design requires EIOC to be on the same IP subnet as the device, while the redundant design requires EIOC primary and backup ports to be on different subnets (following best engineering practices); Support for Parallel Redundancy Protocol (PRP), seamless switching in case of redundant network failure, zero recovery time, and elimination of single point of failure.

Usability design: Native integration with DeltaV system, supporting 5 protocol choices (only 1 at a time, corresponding license required), EIOC and driver updates included in DeltaV system updates; The configuration is completely completed in DeltaV Explorer and Control Studio, consistent with the traditional I/O signal configuration process. The data can be accessed through the DeltaV Live/Operate interface and historical database, reducing the cost of operation and maintenance learning.

Modular redundancy design: The dual level carrier integrates redundant power input terminals and redundant Ethernet isolation ports. Adding one EIOC can achieve redundant configuration, and the system automatically identifies redundant pairs; Redundant Ethernet ports isolate communication between the DeltaV control network and Ethernet device networks, supporting manual triggering of switches in the DeltaV diagnostic browser to ensure high system availability.

Core components and functional details of the product

(1) Core hardware components

Component Name Function Description Key Features

EIOC card embedded data server, realizing communication with Ethernet devices and DeltaV control network. Single card supports 2000 control modules, input power 24V DC ± 10% (single redundancy 325mA max, dual redundancy 575mA max), heat consumption single redundancy 7W max, dual redundancy 13W max, with power/error/main/backup status/communication status LED indicator lights

Double horizontal carrier DIN rail horizontal installation, supporting 1 (single redundancy) or 2 (double redundancy) EIOC cards and auxiliary components, providing redundant 24V DC power interface (1A max) and redundant Ethernet isolation port (copper cable 10/100BASE-TX, RJ45100m), including universal carrier protection cover

Ethernet isolation port enables physical isolation between DeltaV control network and Ethernet device network, supporting only copper twisted pair cables and connected through RJ45 interface to ensure network security and signal stability

The power plug provides 24V DC power input for the carrier and EIOC to adapt to redundant power configuration, ensuring reliable power supply

(2) Support protocols and key functions

1. Core Industrial Ethernet Protocol

Protocol type adaptation equipment key function data access capability

Modbus TCP PLC、 Motor Control Centers (MCC), analyzers, and other Modbus TCP devices (or Modbus serial devices connected through gateways) use EIOC as Modbus clients to read coil/discrete input/input register/hold register data and write coil/hold register data; Only supports MODICON (PLC) addressing, register addresses have range limitations (such as coil 1-9999), 256 devices, 32000 signals

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands