Beijer Mitsubishi Electric E1000 Series Operation Panel

The maximum ambient temperature for horizontal installation is 40 ° C, and for vertical installation it is 50 ° C.

There is an explosion risk warning, such as not disconnecting the equipment before power outage, component replacement may affect applicability, only UL and cUL certified expansion units are allowed to be connected (currently there are no relevant evaluated units), batteries need to be replaced in non hazardous areas, and AWG 28-12 cables need to be used to connect the power supply, with a minimum tightening torque of 0.5 Nm, and can only be used in 4X shell flat rooms.

Beijer Mitsubishi Electric E1000 Series Operation Panel

Safety precautions

UL and cUL installation requirements

The equipment is only suitable for Class I Zone 2 (Groups A, B, C, D) or non hazardous locations. The combination of equipment in the system must be inspected by the local competent department.

The maximum ambient temperature for horizontal installation is 40 ° C, and for vertical installation it is 50 ° C.

There is an explosion risk warning, such as not disconnecting the equipment before power outage, component replacement may affect applicability, only UL and cUL certified expansion units are allowed to be connected (currently there are no relevant evaluated units), batteries need to be replaced in non hazardous areas, and AWG 28-12 cables need to be used to connect the power supply, with a minimum tightening torque of 0.5 Nm, and can only be used in 4X shell flat rooms.

General Safety Rules

It is necessary to carefully read the safety precautions, inspect for transportation damage, and promptly notify the supplier. The use of equipment in high explosive risk environments is prohibited.

Suppliers are not responsible for modifying, altering, or reassembling equipment and may only use components and accessories that meet the supplier's specifications.

Before installation, use, or maintenance, it is necessary to read the relevant instructions to prevent liquids, metal debris, etc. from entering the equipment and causing fires or electric shocks, and only qualified personnel are allowed to operate.

The storage temperature of the device must meet the requirements, otherwise it may cause the LCD display liquid to solidify or denature. If the display liquid comes into contact with the skin or eyes, it should be handled in a specific way.

The illustrations in the manual are for illustration purposes only, and the supplier is not responsible for the actual use based on the illustrations, nor does they guarantee that the equipment is suitable for specific applications or assume responsibility for product design, installation, or operation.

Safety during installation

The operation panel should be fixedly installed on a flat surface without high explosion risk, strong magnetic field, direct sunlight, or drastic temperature changes, and installed and grounded according to the installation instructions, and only by qualified personnel.

High voltage cables, signal lines, and power lines need to be separated, and the voltage and polarity should be confirmed to be correct before connecting the power supply. Peripheral equipment should be adapted to the application scenario and location.

Safety during use

Keep the control panel clean. Emergency stop and other safety functions cannot be controlled by the control panel. Avoid using excessive force or sharp objects when operating buttons or touch screens.

Service and Maintenance of Security

Only qualified personnel are allowed to carry out repairs, following the agreed warranty terms. Before cleaning or maintenance, the power must be disconnected, and the display panel and front cover must be cleaned with a soft cloth and mild cleaning agent. The battery must be replaced according to the supplier's recommended model to avoid accidental replacement and explosion.

Disassembly and scrapping safety

The operation panel or its components need to be recycled according to local regulations. Components such as lithium batteries, electrolytic capacitors, and displays contain substances that may harm health and the environment.

Product Introduction

Product Model Classification and Parameters

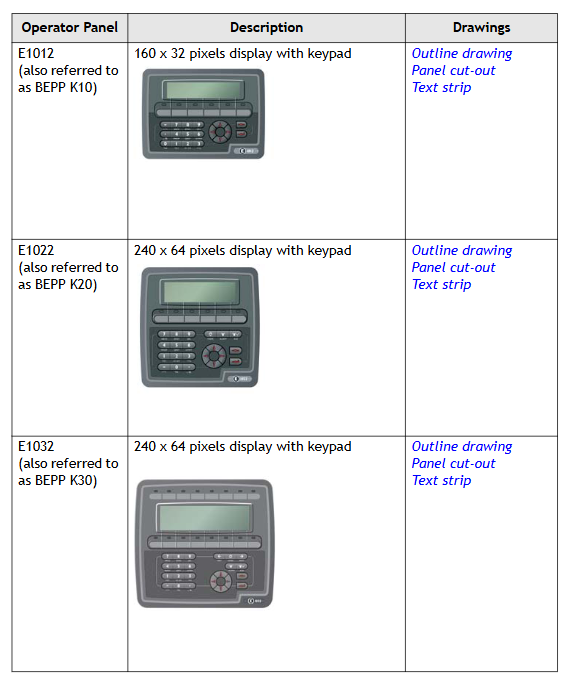

The E1000 series operation panel is divided into keyboard operation type and touch screen operation type. The specific models, descriptions, and corresponding drawings are as follows:

Type and Model Description Drawing

Keyboard operated E1012 (BEPP K10) 160 × 32 pixel display screen with keyboard outline, panel cutout, and text bar

E1022 (BEPP K20) 240 × 64 pixel display screen with keyboard outline, panel cutout, and text bar

E1032 (BEPP K30) 240 × 64 pixel display screen with keyboard outline, panel cutout, and text bar

E1060/E1062 (BEPP K60) 5.7-inch display screen with keyboard outline, panel cutout, and text bar

E1070 (BEPP 64K) 6.5-inch display screen with keyboard outline, panel cutout, and text bar

E1100 (BEPP 104K) 10.4-inch display screen with keyboard outline, panel cutout, and text bar

Touch screen operation type E1041/E1043 (BEPP T40) 3.5-inch touch screen display outline and panel cut diagram

E1061/E1063 (BEPP T60) 5.7-inch touchscreen display outline drawing and panel cutout drawing

E1071 (BEPP 64T) 6.5-inch touchscreen display outline drawing and panel cutout drawing

E1101 (BEPP 104T) 10.4-inch touchscreen display outline and panel cutout diagram

E1151 (BEPP 150T) 15 inch touchscreen display outline and panel cutout diagram

Maintenance Requirements

Before maintenance, it is necessary to carefully read the instructions. Only qualified personnel are allowed to operate. Follow the warranty and license agreement. Equipment damage caused by personnel will void the warranty.

Before cleaning or maintenance, disconnect the power supply and use a soft cloth and mild cleaning agent (such as water, isopropanol, or hexane) to clean the display panel and front cover. The battery should be replaced according to the recommended model to prevent explosion. All repaired parts are covered by a 6-month warranty.

Maintenance personnel can perform operations such as back cover replacement, battery replacement, backlight replacement, and complete front cover replacement.

Service and Maintenance Regulations

Only authorized companies are allowed to provide services and repairs. Unauthorized company operations will result in the warranty being invalidated. If training is required, please contact the supplier.

All maintenance must be carried out within the temperature range of 15-30 ° C. The warranty for equipment damage caused by personnel is invalid, and the customer contract takes precedence over the document information.

Disassembly and scrapping requirements

The operation panel or its components must be recycled according to local regulations. Lithium batteries, electrolytic capacitors, displays, and other materials that may pose a risk to health and the environment.

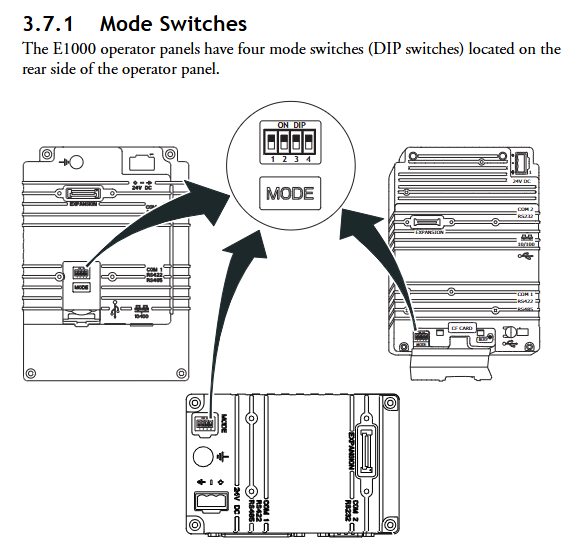

Hardware related content

Hardware Overview

Before the operation panel is launched, it needs to be tested by an independent organization. For example, the E1000 series needs to pass CE, UL and other standard tests. Manufacturers have quality and environmental policy requirements for suppliers and subcontractors.

Hardware Testing

Manufacturers conduct comprehensive hardware testing before obtaining approval for the control panel, with some testing performed by external testing companies such as the Swedish National Testing and Research Institute. All products must pass the testing before leaving the factory.

Hardware specifications

Keyboard operation panel

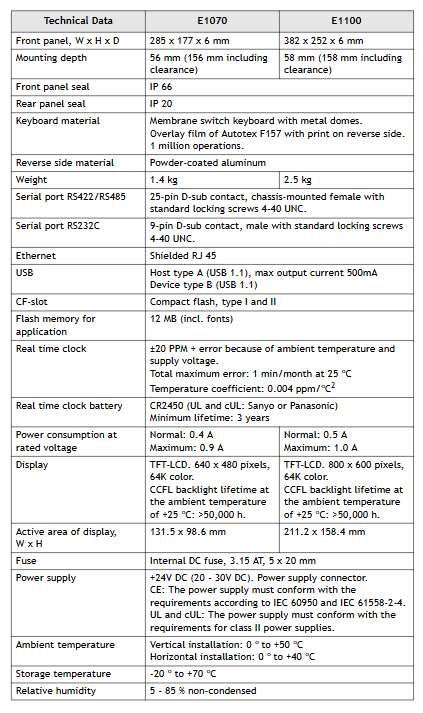

There are differences in the technical parameters of different types of keyboard operation panels, and the following are the main model parameters:

Parameter E1012 E1022 E1032 E1060 (hardware version 07900 and above) E1062 E1070 E1100

Front panel dimensions (W x H x D) 155 x 114 x 6mm 155 x 155 x 6mm 202 x 187 x 6mm 275 x 168 x 6mm -285 x 177 x 6mm 382 x 252 x 6mm

Installation depth 46.4mm (including gap 146.4mm) -57mm (including gap 157mm) -57mm (including gap 157mm) -56mm (including gap 156mm) 58mm (including gap 158mm)

Front panel protection level IP 66- IP 66 IP 66- IP 66-

Rear panel protection level IP 20- IP 20 IP 20- IP 20-

Keyboard material: Thin film switch keyboard with metal shrapnel, Autotex F207 laminated (back printed), operable up to 1 million times - Thin film switch keyboard with metal shrapnel, Autotex F157 laminated (back printed), operable up to 1 million times - Thin film switch keyboard with metal shrapnel, Autotex F157 laminated (back printed), operable up to 1 million times - Thin film switch keyboard with metal shrapnel, Autotex F157 laminated (back printed), operable up to 1 million times-

Back Material Powder Coated Aluminum Powder Coated Aluminum Powder Coated Aluminum Powder Coated Aluminum Powder Coated Aluminum-

Weight 0.45kg 0.55kg 0.95kg 1.2kg-1.4kg 2.5kg

RS232C serial port 9-pin D-sub male, with 4-40 UNC standard locking screw -9-pin D-sub male, with 4-40 UNC standard locking screw -9-pin D-sub male, with 4-40 UNC standard locking screw -9-pin D-sub male, with 4-40 UNC standard locking screw-

RS422/RS485 serial port -25 pin D-sub female head (chassis mounted) with 4-40 UNC standard locking screw, 25 pin D-sub female head (chassis mounted) with 4-40 UNC standard locking screw -25 pin D-sub female head (chassis mounted), with 4-40 UNC standard locking screw-

Ethernet is connected through the Ethernet expansion module installed on the back - shielded RJ45 shielded RJ45 shielded RJ45 shielded RJ45-

USB - A-type host (USB 1.1), maximum output current 500mA A-type host (USB 1.1), maximum output current 500mA - A-type host (USB 1.1500mA), B-type device (USB 1.1)-

Application flash 512kB -12MB (including fonts) 12MB (including fonts) -12MB (including fonts)-

Real time clock ± 20 PPM, affected by ambient temperature and power supply voltage, maximum monthly error of 1 minute at 25 ° C, temperature coefficient 0.004ppm/° C ² - same left same left - same left-

Real time clock battery MS614S (UL and cUL: SII Micro Parts LTD) - CR2450 (UL and cUL: Sanyo or Panasonic), minimum lifespan of 3 years CR2450 (UL and cUL: Sanyo or Panasonic), minimum lifespan of 3 years - CR2450 (UL and cUL: Sanyo or Panasonic), minimum lifespan of 3 years-

Normal power consumption at rated voltage: 0.1A, maximum 0.3A - normal 0.15A, maximum 0.35A - normal 0.2A, maximum 0.4A - normal 0.3A, maximum 0.5A - normal 0.4A, maximum 0.9A - normal 0.5A, maximum 1.0A

Display screen FSTN-LCD, 160 × 32 pixels, monochrome transmission negative display, LED backlight (lifespan>47000h at 25 ° C) FSTN-LCD, 240 × 64 pixels, monochrome transmission negative display, LED backlight (lifespan>47000h at 25 ° C) FSTN-LCD, 240 × 64 pixels, monochrome semi transparent and semi reflective, LED backlight (lifespan>35000h at 25 ° C) TFT-LCD, 320 × 240 pixels, 64K colors, LED backlight (lifespan>20000h at 25 ° C) TFT-LCD, 320 × 240 pixels, 16 grayscale TFT-LCD, 640 × 480 pixels, 64K colors, CCFL backlight (lifespan>50000h at 25 ° C) h) TFT-LCD, 800 × 600 pixels, 64K colors, CCFL backlight (lifespan>50000h at 25 ° C)

Effective area of display screen (W × H) 89.6 × 17.9mm 90.2 × 24.0mm 127.0 × 33.8mm 115.2 × 86.4mm -131.5 × 98.6mm 211.2 × 158.4mm

Internal DC fuse, 1.0AT, 5 × 20mm - Internal DC fuse, 2.0AT, 5 × 20mm - Internal DC fuse, 2.0AT, 5 × 20mm - Internal DC fuse, 3.15AT, 5 × 20mm-

Power supply+24V DC (20-30V DC), power connector; CE: Must comply with IEC 60950 and IEC 61558-2-4; UL and cUL: Must comply with Class II power requirements - Same Left Same Left Same Left-

Environmental temperature 0-50 ° C - vertical 0-50 ° C, horizontal 0-40 ° C - vertical 0-50 ° C, horizontal 0-40 ° C - vertical 0-50 ° C, horizontal 0-40 ° C-

Storage temperature -20-70 ° C -20-70 ° C -20-70 ° C -20-70 ° C -20-70 ° C-

Relative humidity 5-85% (no condensation) -5-85% (no condensation) -5-85% (no condensation) -5-85% (no condensation)-

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands