HONEYWELL EXCEL 5000 OPEN SYSTEM

HONEYWELL EXCEL 5000 OPEN SYSTEM

The Honeywell MVCweb control system is a programmable building automation controller based on open standards (belonging to the Honeywell EXCEL 5000 open system). Its core positioning is to reduce the full lifecycle cost of buildings, while supporting multi scenario building management functions. It has flexible communication compatibility, remote operation and maintenance capabilities, and high reliability, and is suitable for HVAC( heating, ventilation, and air conditioning, heating, ventilation, and air conditioning)、 Building automation scenarios such as energy management and lighting control.

Core Features and Advantages

Cost optimization design

Hardware cost: Reuse existing Ethernet/LAN infrastructure to reduce communication cabling investment; Supports flexible selection of onboard I/O and Panel Bus I/O to avoid redundant configurations.

Operation and maintenance costs: No need to separately maintain the operator interface software (software integrated into the controller, following the "single source principle"); Support remote browser access to reduce on-site operation and maintenance frequency.

Open compatibility and multi protocol support

Communication standard: Fully compatible with international mainstream building communication protocols, including BACnet/IP(ISO 16484-5)、BACnet MS/TP(ISO 16484-5)、LONWORKS(ISO 14908)、Modbus RTU Master、M-Bus(EN 1434-3), Seamless integration with third-party BACnet devices and Honeywell front-end systems (such as Enterprise Buildings integrator) ™、 SymmetrE and LONWorks devices.

Manufacturer independence: Based on open protocol design, there is no need to rely on a single supplier, reducing the limitations of system upgrades and extensions.

Flexible operation and monitoring

Remote access: Built in web server, supports local/remote operation on any networked PC (laptop, desktop, touch screen) through standard browsers (IE 9.0. x, Mozilla Firefox 15.0. x, etc.), compatible with WIN CE system 320x240 pixel touch screen (such as Excel Touch).

Data Trend and Alarm: Supports trend recording for 100 data points; The built-in email/SMS alarm function can send the alarm information to the mailbox or mobile phone through the network or Internet DSL connection, and the alarm rules can be customized.

High reliability and security guarantee

Stable operation: It is equipped with an embedded LINUX system to ensure an independent and safe operating environment, especially suitable for scenarios requiring access to the Internet.

Network security: it needs to be deployed on a private network (such as VPN) or isolated from the Internet through an external firewall; Support 6 levels of user permission management, each level can be configured with independent read and write permissions and passwords to prevent unauthorized operations.

Fault Monitoring: Equipped with M-Bus and Modbus slave device communication fault detection functions, it can automatically retry communication and mark fault status to ensure data collection continuity.

Core functions and technical parameters

1. Control and application capabilities

Function category details

Application scenarios include HVAC control (such as optimal start stop, nighttime purification, maximum load demand control), lighting monitoring, shading control, heat/energy metering, etc

Control performance supports 4 levels of optional control loop priority (multitasking), optional control loop cycle time, event driven switching table, and adapts to the control accuracy requirements of different scenarios

The programming tool allows for free programming through graphical CARE engineering tools, supports existing applications and macro instruction reuse, and has online debugging capabilities

2. Communication interface and parameters

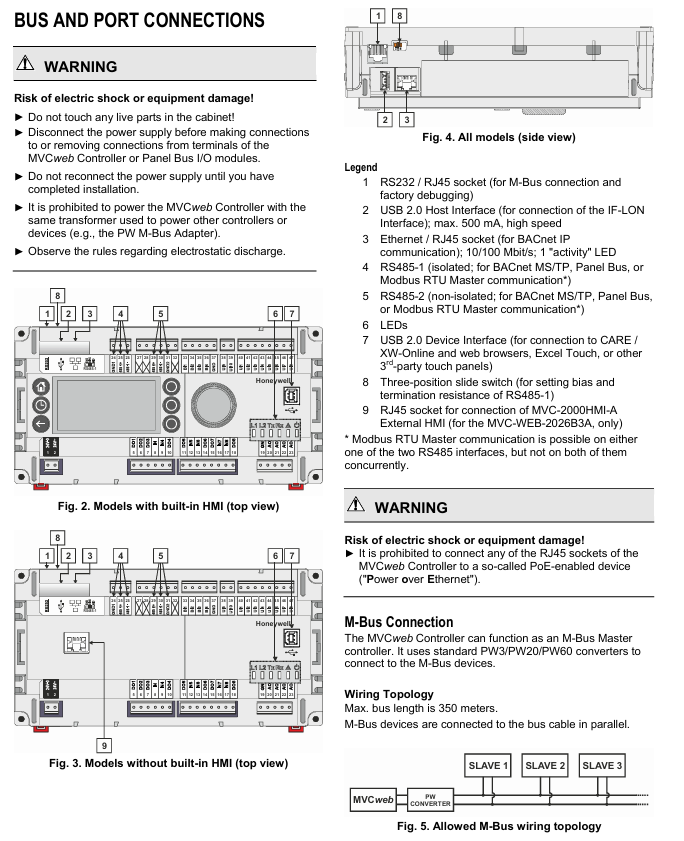

(1) Main communication interface configuration

Number/specifications of interface types, supported protocols/functions, maximum transmission distance

Ethernet (RJ45) 1 10/100 Mbit/s, BACnet/IP communication, browser access, FTP firmware download 100m

RS485 2 (1 isolated, 1 non isolated) BACnet MS/TP, Panel Bus, Modbus RTU Master (only 1 interface can be used simultaneously) 1000m (depending on baud rate)

RS232 (RJ45) 1 M-Bus communication (requires PW3/PW20/PW60 converter), factory debugging 350m (M-Bus)

USB 2.0 2 (1 Host, 1 Device) Host: Connect IF-LON interface (maximum 500mA); Device: Connect CARE tool, touch screen 3m

1 HMI interface (some models) with built-in LCD display screen (5 lines x 20 characters), 6 operation keys, and 1 rotary press key; Some models support external MVC-2000HMI-A 5m (external HMI)

(2) Key communication protocol parameters

M-Bus: Supports 300/2400/9600 Baud, connects up to 60 slave devices, configurable measurement cycle (1-7 days), slave device address range 1-250.

Modbus RTU Master: supports 9.6-115.2 kBaud, can connect up to 32 slave devices, with an address range of 1-247; Supports 16/32-bit registers, with data types including BOOL, INT16/UINT16, INT32/UINT32, FLOAT; Support CRC frame check, 1-2 stop bits, optional parity check (none/odd/even).

LONWorks: Requires IF-LON interface (FTT-10A/FT-X1 transceiver), communication rate of 78 Kbaud, maximum cable length of 320-2200m (depending on topology).

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands