Emerson A6110 Dual Channel Shaft Vibration Monitor

Emerson A6110 Dual Channel Shaft Vibration Monitor

Basic Overview

The A6110 dual channel shaft vibration monitor is a module of the A6000 machine monitoring system, controlled by a microprocessor and used in conjunction with two eddy current measurement chains to measure and monitor the relative shaft vibration of various turbines, compressors, fans, gearboxes, and other equipment. Its two channels can be configured to be used as independent channels or interrelated, with multiple operating modes, and characteristic values can be output through the 0/4... 20mA current of each channel.

CSA Certification

Certification Mark: According to CSA certification requirements, all devices (IMR 6000/xx and A6000 modules) must be labeled with the corresponding CSA label, otherwise the device has not obtained CSA certification.

Acceptance Criteria

Power supply: 24V safe low voltage SELV LPS (C22.2 60950-1) is required for power supply, and the voltage must come from an independent power source.

Installation environment: The IMR system should be placed in a suitable fire-resistant enclosure; The working environment temperature of the system is between 0 ° C and 45 ° C; at least 1 RU (13/4 inches) of ventilation space needs to be provided to prevent heat accumulation. If the ambient temperature of the rack exceeds 45 ° C, equipment such as forced fans and coolers should be used to cool the instrument.

Multi unit installation: When multiple IMR units are installed vertically in a cabinet, a cooling fan bracket needs to be installed in the middle instead of reserving ventilation space. The specific specifications of the cooling fan bracket need to be determined according to the environment and location conditions of the cabinet.

Installation and assembly

Installation requirements: According to the IEC 61010 directive, fixed installation systems must be equipped with power disconnect devices (such as switches or circuit breakers that comply with IEC60947-1 and IEC60947-3). When using an IMR rack, such switches or circuit breakers must be installed in the cabinet, easy for users to operate, and labeled according to the relevant system.

Installation preparation: Installing the A6110 monitor requires a pre prepared 3U slot or other Intermas compatible enclosure in a 19 inch rack, and the slot must be equipped with a 48 pin plug connector (DIN 41612, design F 48 M).

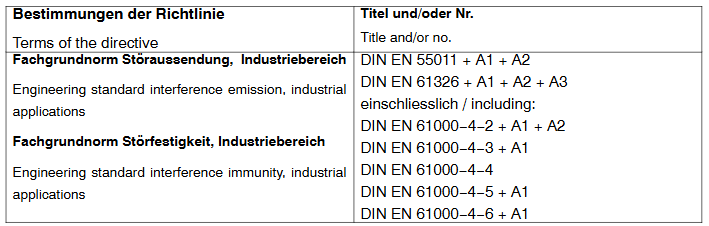

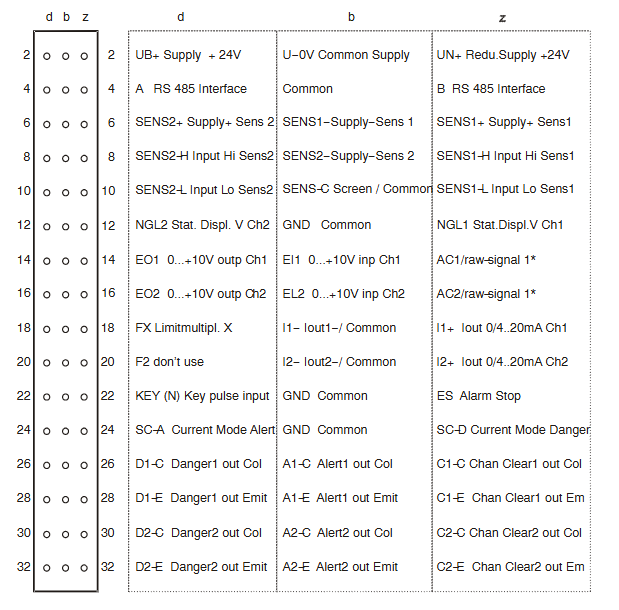

Pin allocation: Detailed pin allocation information is shown in the table below (some key pins):

Pin Position Function Description

2 UN+(+24V), U - (0V/common terminal), UB+(+24V, redundant)

4 A (RS 485), GND (BP, common terminal, RS 485)、B(RS 485)

6 Supply2+(sensor), Supply1 − (sensor), Supply1+(sensor)

8 AIN2- (input), Supply2- (sensor), AIN1- (input)

10 AIN2+(input), GND, AIN1+(input)

18 GWM (limit), I1- (current output common terminal), I1+(channel 1 current output)

20 NC, I2- (current output common terminal), I2+(channel 2 current output)

Jumper settings

RS 485 jumper: When the RS 485 bus is running, the first and last bus devices require electrical terminators, which are implemented through plug-in jumpers on the controller board. Jumper 1-2 is closed: Bus "B" is grounded through a pull-down resistor; Close jumper 3-4: Connect a 120 Ω resistor between "A" and "B"; Jumper 5-6 closed: Bus "A" is connected to+5V through a pull-up resistor. In the delivery state, the jumper is in the open state (bus terminator disabled, reference terminal open circuit). To ensure the fault free operation of the RS 485 bus, the "A" and "B" lines must be connected to their reference terminals (+5V, ground) in one monitor, and the bus terminator jumper of that monitor must be closed.

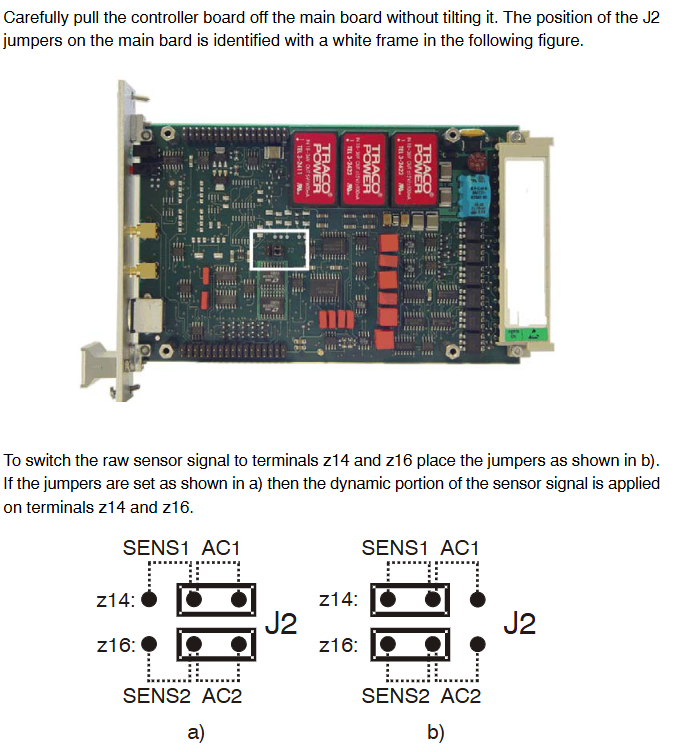

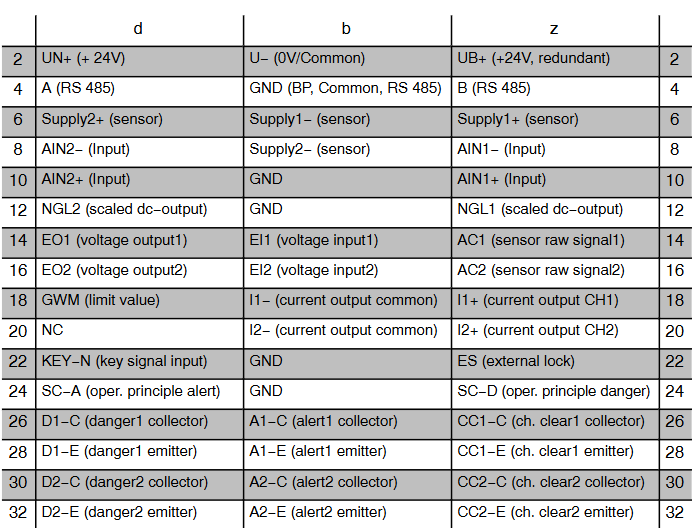

Sensor raw signal jumper: The sensor raw signal (unfiltered in-phase output signal, including AC and DC parts) on the front panel SMB socket can be switched to the z14 (channel 1) and z16 (channel 2) terminals of the connecting strip through J2 jumper. The switching steps are as follows: Use a Phillips screwdriver to remove the four screws, carefully remove the controller board, set the J2 jumper as required (a status is dynamic signal, b status is original signal), reinstall the controller board and tighten the screws. The reference point for the original sensor signal of channel 1 is the connecting strip terminal z6: SENS1+, and channel 2 is d6: SENS2+. If these terminals are connected to the b10 terminal, the reference point is the system ground (GND). At this time, b22: GND and b24: GND can also be used as reference points. During operation, attention should be paid to preventing electrostatic discharge, such as wearing an ESD wristband.

Monitor installation: Before installation, check the slot wiring, push the A6110 monitor into the prepared slot, gently press it to insert it into the plug connector, and then gently tighten the two fixing screws on the front panel by hand. For more information on shielding and grounding, monitor configuration, etc., please refer to the instructions for using the "Shaft Vibration Monitor A6110" (order number 6100-90001).

Technical Specifications

signal conditioning

Measurement input: Channel 1 is z8: SENS1H (+), z10: SENS1L (- signal); Channel 2 is d8: SENS2H (+), d10: SENS2L (- signal). Input nominal range -1.0... -22.16V, limit range 0... -30V DC, input resistance>100k Ω, with differential voltage amplification input, no response, resistant to open and short circuits.

Sensor signal output: front panel SMB socket and/or z14/z16 * (depending on J2 jumper settings), channel 1 is SENS 1 SMB K1, and channel 2 is SENS 2 SMB K2. Signal output -1... -24V, 1:1 with sensor input signal, accuracy ± 1% of full scale, frequency range 0... 16kHz (-3dB) ± 20%, allowable load resistance>100k Ω, internal resistance 1k Ω, resistance to open and short circuits, no response.

Dynamic output: Channel 1 is AC1, channel 2 is AC2, corresponding to z14/z16 * (depending on the J2 jumper setting). The nominal range is 0... 20Vpp, the measurement range is consistent with the measurement range of the characteristic value configuration (minimum 400mVpp, maximum 8000mVpp), the accuracy is ± 1% of the full range, the frequency range is 0.1Hz... 16kHz (-3dB) ± 20%, the allowable load resistance is>10k Ω, the source impedance is 10k Ω, the internal resistance is about 20 Ω, it is resistant to open and short circuits, and has no response.

Scaling DC output: Channel 1 is NGL1, channel 2 is NGL2, corresponding to z12/d12. The nominal range is 0...+10V DC, the measurement range is consistent with the working range of the sensor configuration (0V corresponds to the lower limit of the working range,+10V corresponds to the upper limit of the working range), the accuracy is ± 1% of the full range, the resolution is 12 bits, the allowable load resistance is>10k Ω, the internal resistance is about 50 Ω, it is resistant to open and short circuits, and there is no response.

Characteristic value signal adjustment: The input signal is adjusted by adjusting the amplifier, range dependent amplifier, high pass and low-pass before digitization. The range setting is determined by the configuration, with a minimum measurement range of 400mVpp and a maximum of 8000mVpp. The high pass filter is a second-order Butterworth filter with adjustable parameters (0.5Hz (-3dB) corresponds to a working frequency of 1Hz, 2Hz (-3dB) corresponds to a working frequency of 5Hz), with a tolerance of ± 20%; The low-pass filter is a 5th order Butterworth filter with a parameter range of 50Hz... 2000Hz and a step size of 0.01Hz.

Characteristic value formation: Depending on the configuration, S1 and S2 are separate characteristic values during dual channel operation, and 0-P or S-S evaluation can be selected; The maximum offset S max conforms to the characteristic value A of DIN 45670; the larger vibration amplitude S ppm conforms to the characteristic value B of DIN 45670 or the Max (X, Y) of API 670.

Current output characteristic values: Current output 1 is I1+/I1- corresponding to z18/b18 (0V/common terminal), and current output 2 is I2+/I2- corresponding to z20/b20 (0V/common terminal). The nominal range is 0... 20mA or 4... 20mA (depending on the configuration). When operating at 4... 20mA, the output for fault detection can be set to 0mA (Life zero operation) through configuration settings. The accuracy is ± 1% of the full scale, the resolution is 16 bits, and the load resistance is allowed to be 500 Ω.

Signal output EO 1/EO 2: corresponds to d14/d16, voltage output 0... 10V. Corresponding to characteristic values in independent channel mode, outputs single channel measurement values in S max and S PPmax modes, measurement range and evaluation corresponding characteristic values, can be used for linking or display, resistant to open and short circuits, no response. The nominal range is 0...+10V DC, with a resolution of 8 bits, allowing a load resistance of>10k Ω and an internal resistance of approximately 50 Ω.

Signal input EI1/EI2: Used to connect single channel measurement values 1...+10V for EO output, corresponding to b14/b16. The nominal voltage range is 0...+10V DC, with a resolution of 10 bits and an input resistance of>100k Ω.

Signal input KEY: used for internal speed determination to check the measurement in the analysis of measurement values, corresponding to d22. The signal level is 24V logic (LOW=0... 3V; HIGH=13... 48V), and the input resistance is>10k Ω.

Channel monitoring

Monitoring function: Continuously monitor sensor signals (within the configuration related GOOD range), system voltage (voltage OK), microprocessor functions (watchdog, WD-OK), configuration and setting parameters (C&P-OK), external disable signals (ES).

GOOD threshold: The lower limit is the lower limit of the sensor's working range -0.5V, and the upper limit is the upper limit of the sensor's working range+0.5V.

Channel status: No errors (OK) must meet the requirements of voltage OK, WD OK, C&P OK, sensor signal within the GOOD range, and no external disabling; If not satisfied, it is in an error state; When switching from an error state to an OK state or when the module is turned on, a release delay of 15 seconds (± 2 seconds) is considered as the release delay state.

Visualization: The front panel displays a green LED, which stays on when there are no errors, turns off when there are errors, and flashes when there is a delay in release.

Channel clearing output: The collector/emitter segment of optocoupler isolation, channel 1 corresponds to z26 (collector)/z28 (emitter) for C1C/C1E, and channel 2 corresponds to z30 (collector)/z32 (emitter) for C2C/C2E. When externally disabled, in an error state, or with a release delay, C-E is disabled with a maximum allowable voltage of 48V; when not externally disabled, in an OK state, and without a release delay, C-E conducts with a maximum allowable current of 100mA.

Input external disable ES: corresponding to z22, used to disable limit alarm (such as during maintenance). Input LOW (0...+3V) to disable channel monitoring and limit formation, input HIGH (13... 48V) or enable if not switched.

Limit formation and alarm

Basic settings: Two alarm channels, each with an alarm output ALERT and DANGER, can be individually set with limit values. When the characteristic value exceeds the parameterized limit value (actual value>limit value), an alarm will be triggered.

Limit setting: Through parameter settings, it depends on the measurement operation, characteristic value formation, range, and other configurations. ALERT limit<DANGER limit, set range 0... 100% parameterized measurement range, resolution and reproducibility of 1% (based on full measurement range), configurable lag (0... 20% based on full measurement range, only valid when actual value drops).

Alarm delay: configurable to 0 (off), 1, 2, 3, 4, 5 seconds, effective for alarm output.

Alarm blocking: When C&P is activated, voltage or watchdog is not OK, external is disabled, channel status is incorrect and limit suppression is enabled, channel status release is delayed and channel monitoring is active, the alarm is blocked; Otherwise, do not block (* Determine whether to block the alarm output through channel monitoring in the configuration).

Alarm visualization: Each channel has a red LED, which will turn off when the infinite value is exceeded or the alarm is blocked; When ALERT alarm (no DANGER) occurs, the LED flashes at 2Hz (pulse/pause 1:1); The LED stays on when DANGER alarms.

Alarm output: collector/emitter segment isolated by optocoupler, Alert channel 1 A1-C/A1-E corresponds to b26 (collector)/b28 (emitter), Danger channel 1 D1-C/D1-E corresponds to d26 (collector)/d28 (emitter), Alert channel 2 A2-C/A2-E corresponds to b30 (collector)/b32 (emitter). When C-E is disabled, the maximum allowable UCE is 48V. When C-E is conductive, the maximum allowable ICE is 100mA. The alarm state is open circuit mode conductive, and closed circuit mode disabled.

Open/Closed Circuit Mode: Switch between digital inputs SC-A and SC-D through external signal selection. ALERT switching: d24-SC-A=HIGH/unconnected for open circuit mode,=LOW for closed circuit mode; DANGER switching: z24-SC-D=HIGH/unconnected for open circuit mode,=LOW for closed circuit mode. Switch level LOW=0...+3V, HIGH=13... 48V, input resistance>10k Ω.

communication interface

RS 232 interface: front panel socket, used for connecting laptops/computers for configuration and visualization, front panel circular plug connector is a mini DIN socket type TM 0508A/6, used for parametric cables (included in the operating kit).

RS 485 interface: d4, z4 bus interface, used for communication with MMS 68xx epro analysis and diagnostic system and configuration software.

Power supply

Power supply voltage input: Two redundant diode decoupled inputs, nominal+24V, shared 0V reference. Voltage input UB+/UN+corresponds to d2/z2, common reference 0V U - corresponds to b2. The allowable voltage range is 19... 31.2VDC (IEC 654-2 class DC 4), CSA requires 24Vdc; SELV LPS。 The maximum power consumption is 6W, and the maximum is 250mA at 24V.

Monitoring system voltage: The monitoring system voltage required for internal power supply continuously monitors undervoltage and generates an error message when undervoltage is detected.

Sensor power supply: The sensor power supply for two channels is diagonally separated from the supply voltage and can operate in parallel with other monitors. It is resistant to open and short circuits and has no response. Sensor power channel 1 is SENS1-/SENS1+corresponding to b6/z6, and channel 2 is SENS2-/SENS2+corresponding to b8/d6. Supply voltage 2

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands