Reliance Electric Engineering Drive System and DBU Dynamic Braking Unit

Reliance Electric Engineering Drive System and DBU Dynamic Braking Unit

Engineering driven system is a complex system composed of multiple independent driving components working together to meet specific industrial application requirements. These components may be integrated as standard parts after selection and modification, or they may be specialized hardware or software designed for customized applications. Regardless of whether the components have been modified or not, their runtime as part of the system may involve factors not covered by standard documentation, especially for customized hardware or software. Therefore, engineers and technicians involved in the installation, debugging, and maintenance of the drive system must have a deep understanding of Reliance Electric ® Standard practices and documentation system for engineering drive systems.

Safety standards and responsibility definition: the cornerstone of all operations

Safety is the primary prerequisite for managing the entire lifecycle of a driving system. At the beginning of the manual, the DANGER and Warning signs emphasize the crucial safety principles:

Personnel qualifications: Only electrical personnel who are familiar with the structure, operation, and related hazards of the equipment and have obtained qualifications are allowed to carry out installation, adjustment, operation, and/or maintenance work. Before starting any work, it is necessary to read and understand this manual in its entirety.

Compliance with specifications: The user is responsible for ensuring that the installation complies with all applicable local, national, and international electrical regulations. Among them, wiring practice, grounding, disconnection devices, and overcurrent protection are particularly important.

Modification permissions: Only qualified Reliance personnel or other trained individuals who understand potential risks are allowed to modify rack configurations, variable configurations, and application tasks. Any unauthorized modifications may result in equipment loss of control.

In addition, the responsibility is clearly defined: Reliance Electric is responsible for the design and manufacture of the driving electrical equipment itself in accordance with applicable specifications and standards, but is not responsible for construction projects, utility power supply, equipment installation, or on-site compliance with specifications (unless the contract explicitly includes installation services), nor is it responsible for the specifications, design, or operation of the driven equipment (such as machine tools, production line machinery). The specifications, locations, and functions of the operation station, emergency disconnect device, protective cover, or other safety equipment/procedures should be provided by the user, mechanical designer, or original equipment manufacturer (OEM) in accordance with safety regulations and are not within the scope of responsibility of Reliance Electric.

Device reception, identification, and initial management

1. Reception and Inspection

In most cases, the sales terms of Reliance Electric are FOB (Free On Board). Even if otherwise agreed in the contract, it is strongly recommended that users thoroughly inspect and count the goods before receiving them from the transportation company. Do not sign the receipt before inspection. If damage to the outer packaging is found, it must be noted in writing on the waybill before signing for it. If hidden damage is found after opening the box, the carrier should be immediately contacted to request inspection and notify Reliance.

2. Device identification

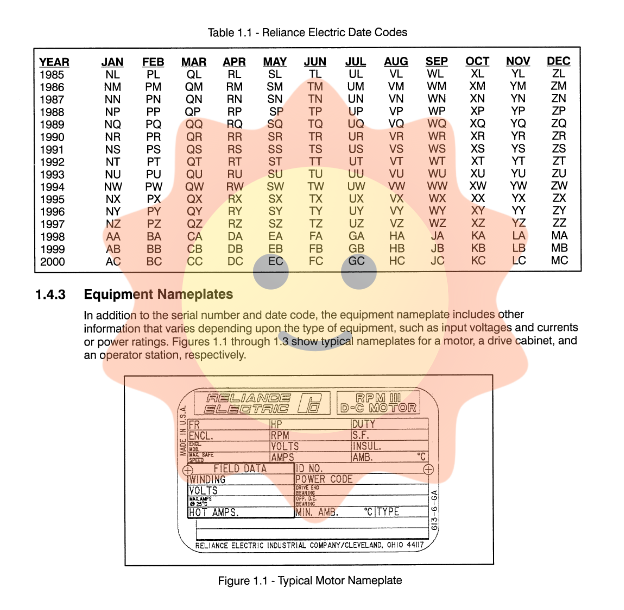

Each major device in the system has a unique serial number (such as 10TT-847000-V1), engraved on the nameplate and recorded in the system manual. This serial number is a key identifier for subsequent communication, service, and spare parts ordering. It consists of a sales order number (S/O), a sub order prefix (such as 10TT), and multiple suffixes (such as V1, V2). In addition, the manufacturing date is represented by a two letter code (see Table 1.1).

3. Handling and Storage

Control equipment: The equipment dimension diagram (D/S) and the specialized lifting procedure described in Chapter 3 of the manual must be used. The storage environment temperature should be between 0 ° C and 60 ° C (32 ° F to 140 ° F), with a relative humidity of 5% -95% (non condensing).

Rotating equipment (motors, etc.) should be lifted using lifting rings or slings on the frame, and should not be lifted through shaft extensions. The maximum ambient temperature for storage is 10 ° C to 50 ° C (50 ° F to 120 ° F), and the maximum humidity is 60%. Inventory motors should rotate once every three months to prevent rusting caused by the failure of bearing and raceway grease protection.

Long term storage: Temperature, dust, vibration, corrosive atmosphere, and humidity need to be controlled. For control cabinets, space heaters are required if the temperature is below 0 ° C, and cooling is required if the temperature is above 60 ° C. When stored in non dust-free environments, the equipment should be sealed and wrapped with polyethylene film. Electrical equipment should not be stored in a corrosive atmosphere unless it is placed in a sealed container filled with protective gas.

System documentation: "Map" for installation and maintenance

Reliance Electric provides a standard document set for each engineering drive system, which is the core basis for understanding, installing, and maintaining the system.

1. Engineering drawings

Drawings are usually identified by a two letter prefix followed by a six digit number. The main types include (see Table 2.1):

W/E (Electrical Schematic): It displays the electrical connections between electronic and electrical equipment in the system, and is a functional representation that does not reflect physical dimensions or positions. Includes additional instructions, standard notes, and on-site wiring information.

W/D (Wiring Diagram): Reference diagram for standard components, including schematic diagram.

W/L (Panel Layout): Display the physical layout of electrical equipment on the control panel, including customer wiring terminals with wire numbers. The drawings themselves also serve as a Bill of Materials (B/M).

W/M (Motor Control Center Diagram): Display the positions of each unit in the motor control center and their corresponding W/E diagrams.

W/F (process diagram): may include process flow (drive section, motor relationship diagram), communication single line diagram, AC power single line diagram.

W/I (Interconnection Wiring Diagram): Optional, listing a list of all interconnected on-site wiring between components.

W/S (Construction Drawing): Provide installation information for Class A or Class B open mill control or control rooms, including overall dimensions, installation details, and conduit inlet locations.

W/N (Annotation Page): Describe wiring instructions, define standard annotations and terminology used in the drawing.

W/O (Operator Station Diagram): Display the layout of operating equipment and the location of on-site terminals.

W/P (Program Document): Application task diagram based on software system.

W/X (index page): List the descriptions, last revision dates, and other information of all drawings in the sales order.

The drawing adopts ANSI/NEMA standard equipment symbols. After the equipment is shipped, the W/E, W/M, W/P drawings and software list will be updated based on changes during manufacturing and testing, and will be updated again after startup as a revised page of the "Instruction Manual".

2. Instruction manual

The instruction manual is a complete record of the supplied equipment, including a list of equipment, operation description (optional), various manuals (motors, speed measuring machines, etc.), dimension tables, electrical diagrams (reduced version), engineering data, and spare parts list. For software based systems, it also includes a documented list of operating system and application disks, as well as customized application software.

3. Component identification

All components used in the system have Reliance Electric part numbers or component numbers for replacement. The main types include commercial part numbers (with suffix "CPx"), customer property part numbers (with prefix or suffix "CPT"), Reliance Electric standard part numbers, and standard models. When ordering spare parts, the complete part number must be used.

Mechanical installation considerations: creating an ideal 'home' for equipment

The physical environment of the driving system directly affects its operational reliability and lifespan.

1. Site planning

Space requirements: Adequate ventilation and maintenance access space must be provided for the equipment. Table 3.1 lists the minimum front to back and top clearances required for various types of equipment (wall mounted control boxes, floor standing consoles, cabinets, rolling mill control rooms, etc.). In addition, it is necessary to meet the requirements of Articles 110-16 of the National Electrical Code (NEC) for workspaces.

Installation and anchoring: All equipment must be securely installed on a rigid structure or foundation, with a flat installation surface to avoid equipment deformation or stress. The supporting structure of rotating equipment must be able to withstand torque and equipment weight.

Wiring channel: All dimensional drawings of the casing indicate the location where conduit can be installed with openings.

2. Operating conditions

The equipment design is suitable for the standard service conditions defined by NEMA. If exceeded, special treatment or selection of a higher protection level casing is required.

Altitude: The standard design is suitable for altitudes below 1000 meters (3300 feet) and does not require derating. For higher altitudes, consult a sales engineer.

Corrosive environment: optional NEMA 4X enclosure, or introducing clean air into the control cabinet and installing it in an air-conditioned environment. The motor should be of the fully enclosed enhanced type (XT).

Dust: Insulation dust increases contact resistance, while conductive dust causes short circuits. NEMA 12 or NEMA 1A cabinets with positive pressure ventilation and filters can be selected, or the equipment can be installed in the air conditioning control room. The motor can be selected as a forced air cooling or fully enclosed type with a filter.

Dangerous area: Drive control equipment should not be installed in dangerous (classified) areas unless the equipment has obtained the corresponding certification. The motor can be equipped with a fully enclosed or explosion-proof casing filled with clean air.

Humidity: The operating humidity range is 5% -95% (non condensing). Excessive humidity or condensation can cause short circuits or corrosion. DC motors require an absolute humidity of at least 2 grains per cubic foot to prevent excessive wear of the brushes.

Shock and vibration: can cause electrical connection failures, component looseness, or misoperation. Reliance Electric can provide mechanical consulting services.

Temperature: The maximum operating environment temperature is 40 ° C (without derating), and the minimum is 0 ° C. If exceeded, derating, auxiliary cooling, or heating are required. Equipment cooling requires free circulation of surrounding air, especially for non ventilated equipment.

3. Installation and startup steps

Site preparation: Ideally, all construction should be completed in the room where the equipment is located, the floor should be cleaned and sealed to reduce dust, and the air conditioning/filtration system should be in place and running. If it cannot be achieved, the equipment needs to be protected from cement dust, chemical atmosphere, condensation, extreme temperature, and physical damage.

Unpacking and handling: Protective packaging should be removed after the equipment reaches its final installation position. All provided eyebolts or lugs should be used, and suitable slings, crossbeams, and pads should be used to balance the load. The motor/reducer/base plate assembly must be lifted through the base plate, and the motor and reducer must be disconnected.

Calibration and anchoring: Before final anchoring, check if the equipment is level and if all anchoring points are adequately supported, using steel shims if necessary.

Installation of conduits: When opening holes in the casing, internal components must be protected from metal shavings and other debris. After installation, the cabinet should be cleaned.

Installation of rotating equipment: The alignment and anchoring of motors and reducers are crucial for their operational lifespan. Misalignment may lead to speed/torque fluctuations and even bearing/shaft failures. Please refer to the installation manual of the specific equipment. When the speedometer, pulse generator or rotary transformer is coupled with the motor, centering is particularly critical, and a flexible coupling with high torsional rigidity (such as Reliance part number 406041-A) must be used. It is the responsibility of the user to install suitable protective covers on rotating components such as couplings.

Electrical installation considerations: Ensure precise and stable operation

1. Responsibilities and Standards

The user and their electrical contractor are responsible for correctly installing the equipment according to the instructions in this manual and the engineering drawing package. Reliance Electric does not guarantee the performance of systems that do not comply with its recommendations, particularly regarding noise prevention requirements for signal lines. Electrical contractors must comply with all applicable power and control wiring specifications.

The main reference document is NFPA 70 National Electrical Code (NEC). Other relevant standards include NFPA 79, NEMA ICS series, IEEE 518, etc.

2. Key regulatory requirements

Branch circuit protection: Drive overload and short circuit protection may not necessarily provide branch circuit protection, and it needs to be designed in coordination with the upstream feeder length, cable rating, and upstream protection device.

Disconnecting device: If not provided by Reliance, a disconnecting device must be installed within 50 feet of the drive equipment and visible from the drive cabinet, with a rated value of at least 115% of the full load current.

Grounding: All non current carrying metal casings must be grounded. It is recommended to use high resistance grounding for the secondary of the isolation transformer that supplies power to the speed control drive to limit arc damage caused by grounding faults. Attention: The input and output circuits of the same speed regulation drive cannot be grounded simultaneously. All low-level signals and regulator circuits should be designed without grounding.

Wire gauge: Reliance Electric's W/E drawings provide full load current and voltage ratings for all power circuits, which can be used to select wire types and sizes according to NEC.

3. Wiring level and noise protection

According to the ANSI/IEEE 518 standard, system wiring is classified into four levels based on the sensitivity or ability of the circuit to noise, and must be physically isolated during installation to prevent noise interference:

Level 1 (high sensitivity): such as<50V analog signals,<15V digital signals, 4-20mA signals, rotary transformers, communication lines (coaxial cables, optical fibers), etc.

Level 2 (medium sensitivity): such as>50V analog signals,<50V switch signals, indicator lights, buttons, limit switches, etc.

Level 3 (low sensitivity): such as>50V switch signals, AC feeders below 20A, contactor coils, etc.

Level 4 (power circuit): such as>20A or>250V AC feeder, motor armature circuit, etc.

Key installation practices (based on IEEE 518 and Reliance experience):

Spacing requirements: Tables 4.1, 4.2, and 4.3 provide detailed specifications for the minimum spacing between cable trays, conduits and cable trays, and conduits, with different requirements for different grades.

Wiring rules: Different levels should be routed through separate conduits or cable trays. Level 1 and Level 2 trunking must have solid bottom and cover plates, and should be made of steel to provide magnetic shielding. When necessary, Level 1 and Level 2 can be separated by grounding steel partitions in the same trunking. When different levels intersect, they should form a 90 degree angle. When entering the junction box, isolation should be maintained. Wiring should be kept as far away as possible from high-power equipment greater than 100KVA.

Signal line specifications: Table 4.4 provides recommended signal line models (such as Reliance part number 417900-92DAD for long-distance twisted pair cables). For the wiring of rotary transformers, it is recommended to use unshielded twisted pair cables with at least 2 twists per inch (half inch pitch). The specific model and maximum distance are shown in Table 4.7.

Special cables:

Coaxial cable: used for high-speed communication (such as R-Net) ™ The internet). RG-59/U is the standard, RG-11/U has better performance/used for longer distances. It needs to be processed according to Level 1 wiring and separated from all power and control lines. Refer to the corresponding manual (such as J2-3009) for installation details.

Fiber optic cable: used for AutoMax distributed systems. 62.5/50 micron duplex optical fiber (specifications as shown in Table 4.6) needs to be selected. Special attention should be paid to protection during installation to avoid excessive bending, stretching, or contact with chemicals. It is recommended to have experienced contractors carry out installation and termination.

Coil suppression: If the wiring with third-party equipment enters the Reliance cabinet or shares conduits/trunking, all relay and contactor coils in the third-party equipment must be installed with suppression circuits as shown in Figure 4.3.

4. Connect the wires to the drive cabinet

The on-site wiring entering the Reliance cabinet (NEC defined as "house wiring") must comply with the above IEEE isolation rules and should enter from the designated conduit entry point closest to the provided terminal (see dimension diagram). It is strictly prohibited to mix the wiring of the house with the wiring inside the cabinet in the internal trunking, nor to cross areas not designated for customer wiring, otherwise it may affect the warranty of related circuits.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands