How to operate Emerson Motion Control FX 490?

Emerson Motion Control FX 490

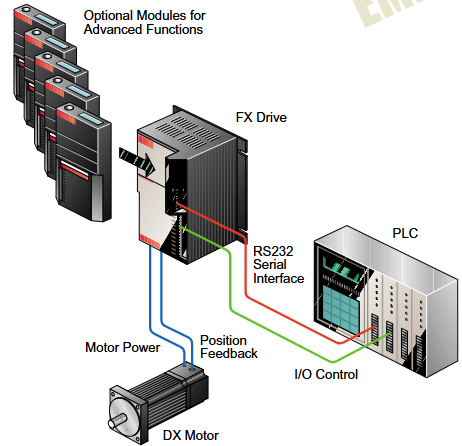

Overview of FX Series Positioning Servo Drive System

The FX series positioning servo drive system is a servo solution with over ten years of application history. By combining FX drivers with PCM modules, it can solve various common applications and is the foundation of the "Motion Made Easy" series solutions. This system is based on the 2000 Emerson Motion Control Servo Solution Catalog information and adopts a fully digital design, suitable for multiple torque ranges. It is compatible with DX series (0-120 lb in) and BL series (120-1000 lb in) rotary transformer feedback servo motors, and some models have UL certification, Canadian UL certification, and CE certification.

Core Features

Flexible power and torque: Supports multiple power inputs and can provide continuous torque from 0-1000 lb in. Some models have IP65 protection and brake versions.

Convenient programming: Use Emerson Motion Control's PCXWin or DOS version PCX software, with fill in the blank operation for easy programming.

Rich I/O and operation modes: Standard equipped with 8 inputs and 4 output lines (10-30 VDC), supporting sinking or sourcing modes; The operating modes include integral locator, simulated speed, simulated torque, and pulse follower.

Scalability: Application modules can be installed to increase I/O, memory, and special application functions. The basic module can start up to 100 steps of motion sequence programs, and adding application modules can reach 1024 steps.

Communication and Storage: Equipped with RS-232 communication interface, with a maximum baud rate of 19.2 Kbaud, it can daisy chain up to 31 FX drives on a single communication link; Non volatile memory can store up to 32 sets of index parameters.

Other features: Supports linear or modified sine motion curves, can be scaled in user-defined units such as inches, feet, millimeters, etc., has auxiliary logic power supply to maintain critical driving information in case of bridge power loss, is equipped with LED display for displaying operation and diagnostic status, and offers a two-year extended warranty.

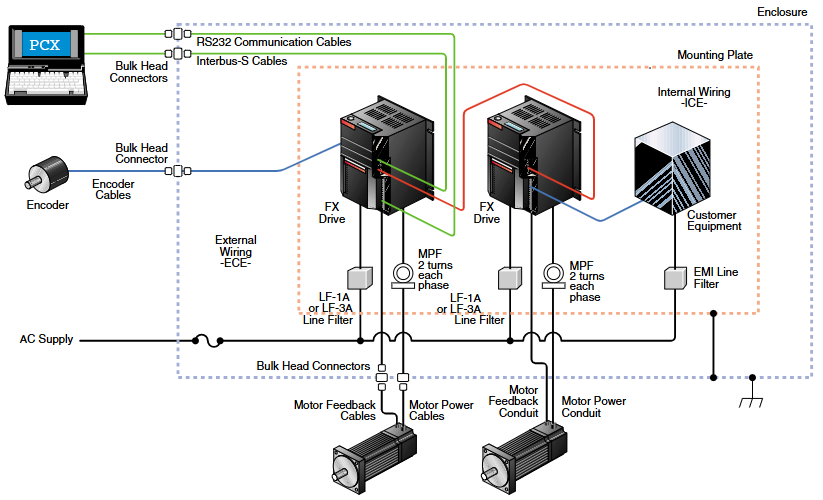

CE marking FX system

Certification and Scope: Compliant with EMC Directive 89/336/EEC and bearing the CE mark, with a continuous torque range of 8-120 lb in, a peak of 200%, and a maximum duration of 1.5 seconds. The amplifier is UL certified and the motor is UL approved, providing complete motion control system components.

Configuration and wiring: The CE marked FX driver has the same functionality and performance specifications as the standard FX driver, and is set using PCX programming software; There are two system wiring methods that meet CE grounding and shielding requirements, both requiring power lines and motor power filters.

Application module

The FX series offers a variety of application modules that can be easily installed on any FX driver front-end, enabling advanced positioning functions such as phase synchronization, proportional control, web control, and rotary tool cutting. It is programmed using the same PCX software as the basic FX driver, with parameters stored in non-volatile memory and movable between different drives. The main application modules include:

PCM-11 motion program controller: suitable for various applications such as composite indexing and packaging machinery.

PCM-14 slip compensator: used for slip compensation, automatic coil feeding and other scenarios.

PCM-15 proportional controller: capable of implementing functions such as flying shears and electronic spools.

Other modules, such as PCM-16 phase synchronization controller and PCM-17 random feed controller, each have their specific application areas.

Operation mode

Position control mode: The microprocessor executes user-defined motion control functions and can store multiple indexes. After adding application modules, the index storage capacity and functions can be expanded.

Pulse sequence following mode: Each received pulse generates incremental axis rotation, which can directly replace existing stepper positioning systems.

Simulation mode: includes two options: simulated speed and simulated torque, and all motion and system limitations are effective in this mode.

Software and Programming

PCX programming software: intuitive and simple, no need for advanced programming language knowledge. After the user inputs the motion parameters, the software completes the relevant operations and can complete the system settings in a short time.

Configuration and parameter settings: including driver parameter configuration, motion parameter definition (such as jogging, indexing, etc.), I/O settings, etc.

Specifications and Performance

System specifications: Different models of FX drivers have specific parameters in terms of recommended line current, motor torque, motor rotor inertia, rated power, maximum motor speed, and the shortest time to reach maximum speed.

Brake specifications: Each model of brake has clear data on maintaining torque, inertia, weight, coil voltage and current, engagement and release time, etc.

Driver specifications: including input power supply voltage, control mode, serial interface, programming method, diagnostic indicators, noise immunity, I/O circuit specifications and capacity, resolution, performance, motor housing, environmental specifications, etc.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands