Honeywell HA71 Digital Gas Controller

Honeywell HA71 Digital Gas Controller

Product Overview

HA71 is a multi-channel digital gas controller launched by Honeywell, supporting up to 16 detection channels (configurable as 8-channel mode). Its core functions are real-time monitoring, alarm control, and data management, suitable for safe monitoring of toxic gases, flammable gases, and oxygen content in industrial environments. Its design emphasizes modular expansion, high reliability, and flexible communication capabilities, which can receive data through analog input or Modbus protocol, and support integration with upper level systems such as PLC and DCS.

Core functions and features

1. System configuration and input/output

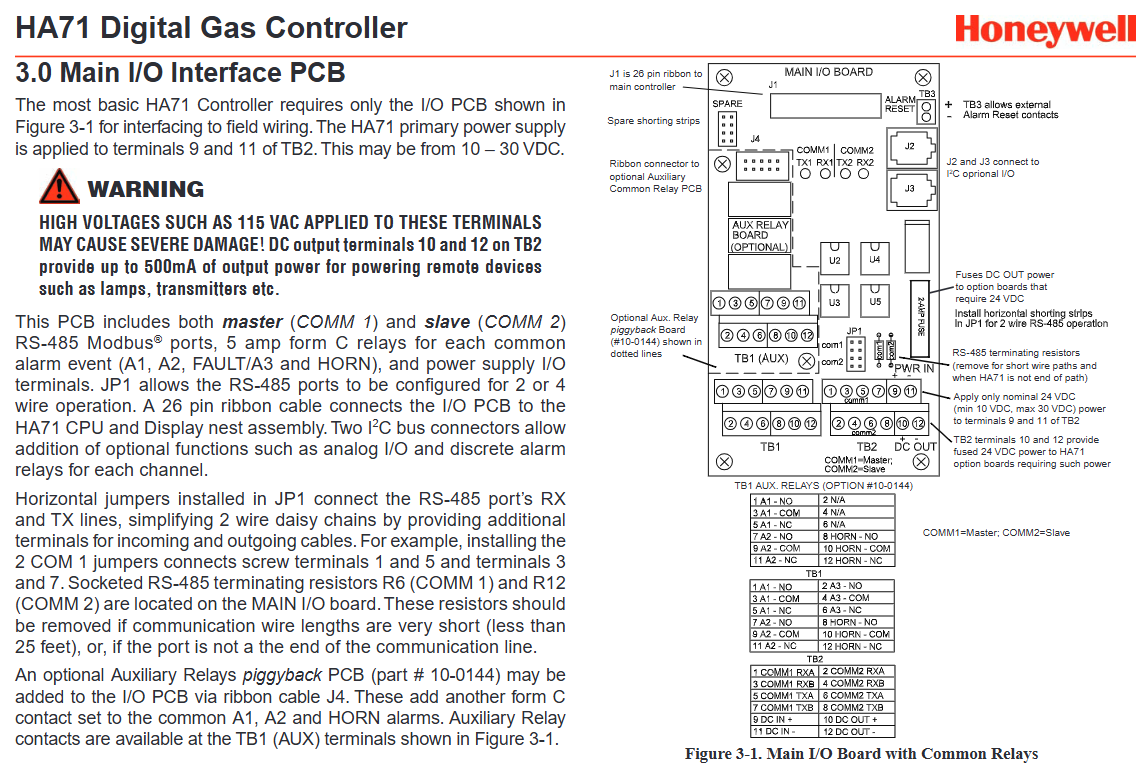

Channels and inputs: Basic support for 8 channels, expandable up to 16 channels, compatible with analog signals (4-20mA, mV) and Modbus RTU protocol inputs, can directly connect catalytic bead sensors, RTD temperature sensors and other devices.

Output and Control:

Standard configuration of public alarm relays (A1, A2, fault, horn), supporting 3-level independent alarms (high, medium, and low alarm thresholds can be set for each channel).

Optional discrete relays (corresponding to 12/24 channels per channel) and 4-20mA analog outputs are available for driving external devices such as sound and light alarms and valves.

Power supply and power consumption: Supports 10-30VDC power supply, optional 150W AC/DC power supply (110-240VAC input, 24VDC output), total power consumption up to 210W (including expansion unit).

2. Display and operation

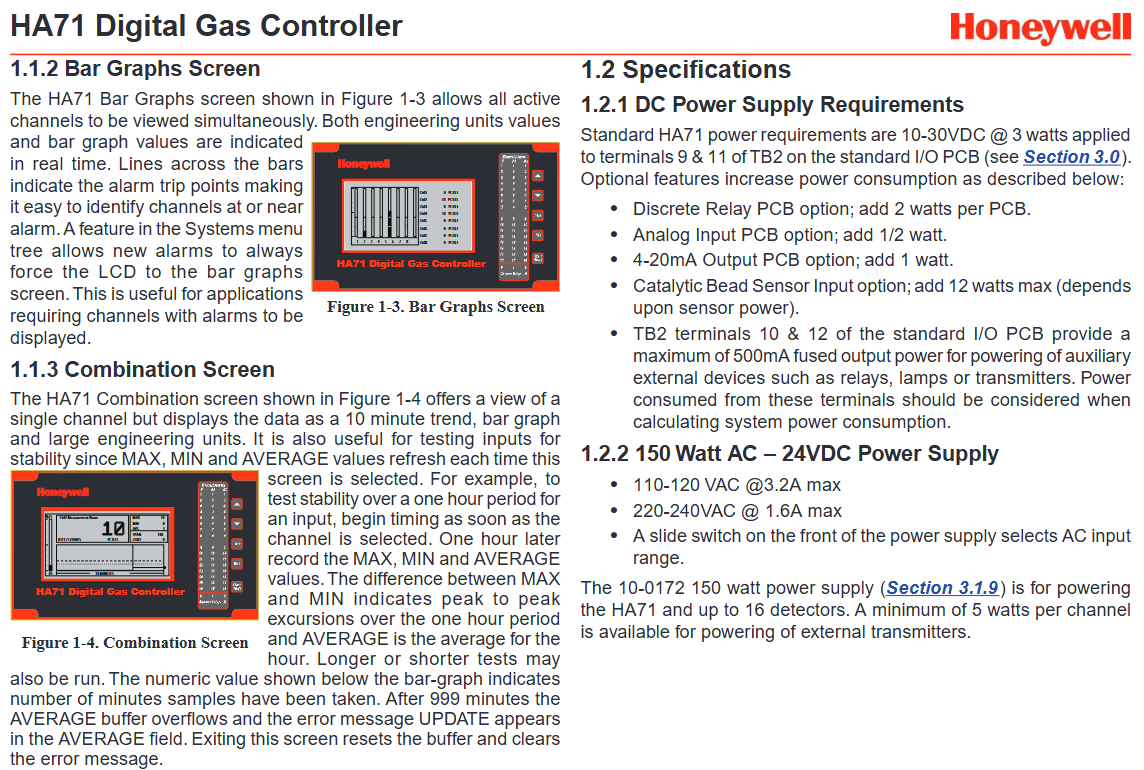

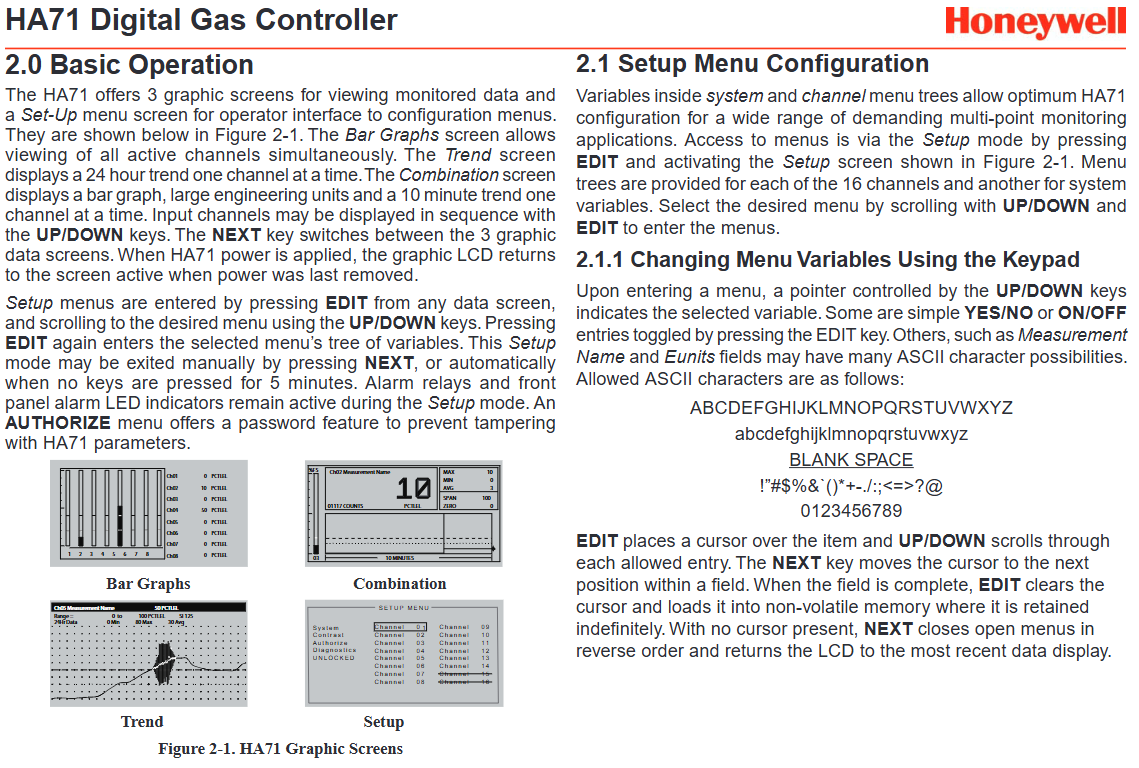

Interface design: 240 × 128 pixel graphic LCD, providing 3 data views (bar chart, 24-hour trend chart, combination view), supporting visual display of engineering units and alarm thresholds.

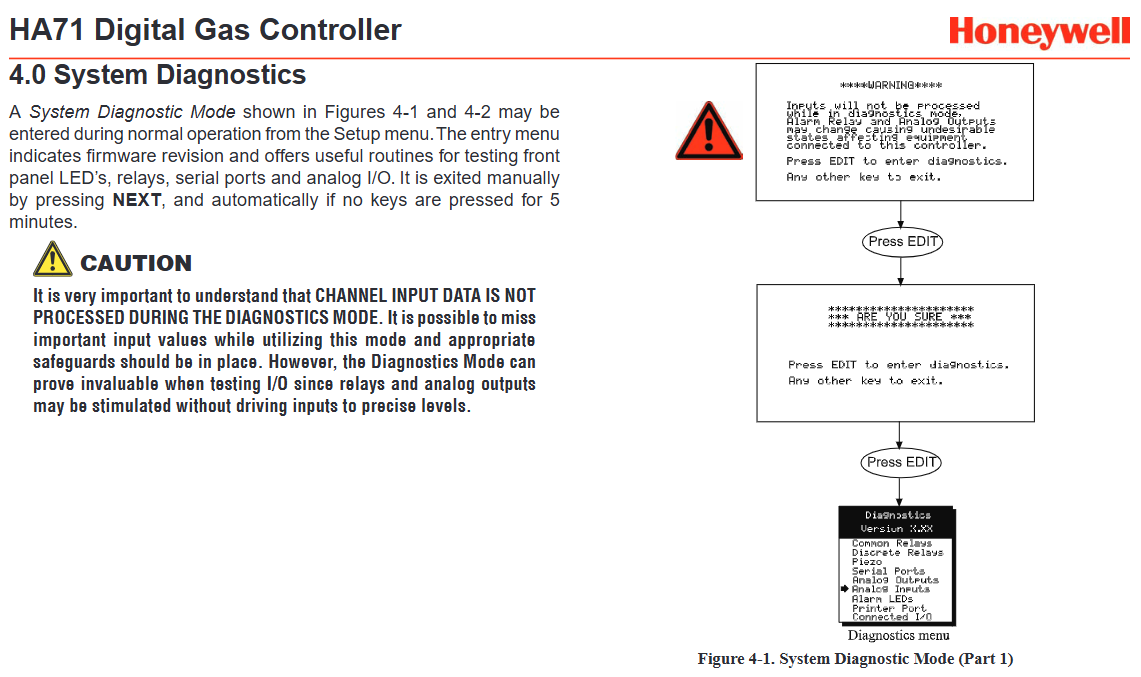

Operation mode: Non invasive magnetic keyboard (suitable for hazardous areas), supports password authorization mode (locking key configurations), built-in calibration mode (zero/range calibration).

Alarm indication: Each channel is equipped with green yellow red three color LED (normal/fault/alarm), and the sound alarm is ≥ 70dB@1 Mi, supports remote reset and mute functions.

3. Communication and Data Management

Communication interface: comes standard with dual Modbus RS-485 ports (master-slave mode), supports Modbus TCP/IP (optional 10 BaseT Ethernet), and can be networked with multiple machines (up to 128 HA71).

Data recording: Supports SD card storage configuration, event logs, and historical data, with optional printer interface (real-time printing of alarm events with timestamps).

Environmental adaptability and certification

Protection level: Multiple enclosure options are available, including NEMA 4X (dustproof and waterproof, suitable for outdoor use), 316 stainless steel enclosure (corrosion-resistant), NEMA 7 explosion-proof enclosure (suitable for Class I, Div. 1/2 hazardous areas).

Working environment: temperature -25 ° C to+50 ° C, humidity 0-90% (non condensing), altitude up to 2000 meters.

Certification standards: Compliant with safety and electromagnetic compatibility standards such as CSA C22.2, UL 1604, EN 55011, etc., with a safety integrity level of SIL2.

Modular expansion and installation

Optional modules:

Analog input board (8 channels, supporting 4-20mA/mV signals), discrete relay board (8 channels, 5A contact capacity).

Catalytic bead sensor interface board, RTD/4-20mA hybrid input board, 4-20mA output board.

Clock/printer interface board (supports parallel/serial printing, records alarm events).

Installation method: Supports wall mounted, panel mounted, or 19 inch rack mounted installation, with preset cable entry (PG16/M20 specification) to simplify wiring.

Applicable scenarios

Typical applications: Chemical workshops, oil and gas facilities, laboratories, and other scenarios that require multi-point gas monitoring can be integrated with Honeywell Sensepoint series detectors to form a complete system.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands