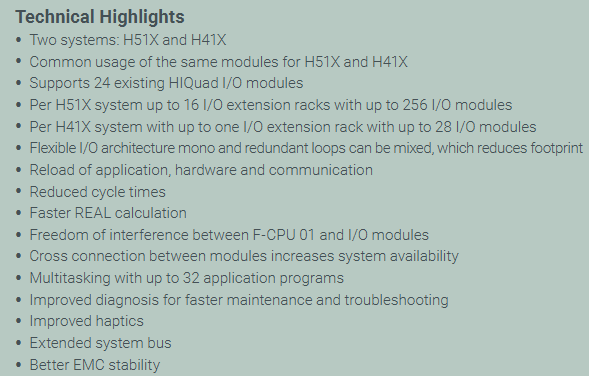

HIMA HIQuad X Safety System

The F-FAN 01 system fan has a 19 inch specification and a height of 1U, providing heat dissipation for the rack and ensuring stable operation of the module

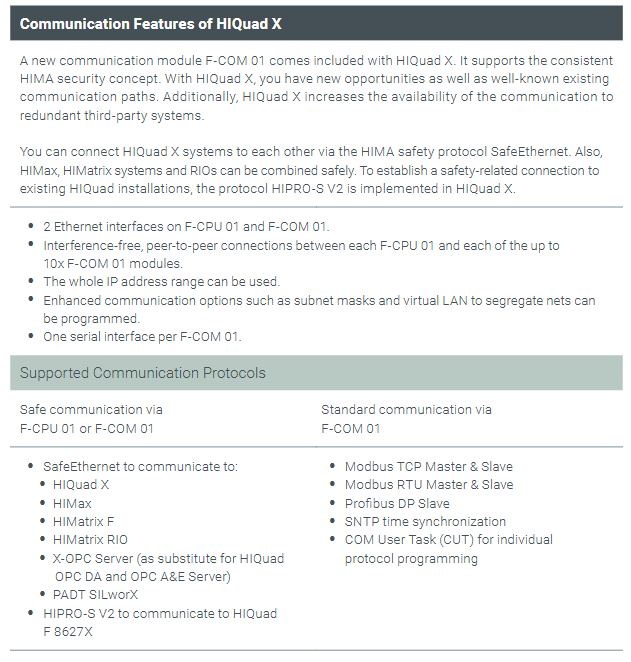

Communication function and protocol support

(1) Advantages of Communication Architecture

Hardware and connectivity flexibility

Both F-CPU 01 and F-COM 01 are equipped with two Ethernet interfaces, supporting redundant communication;

F-COM 01 supports up to 10 modules to establish interference free point-to-point connections with F-CPU 01, expanding communication capacity;

Support the use of complete IP address segments, configurable subnet masks and virtual local area networks (VLANs) to achieve network segmentation isolation and enhance communication security.

Secure Communication and System Interconnection

Implementing secure communication between HIMA systems through the SafeEthernet protocol, supporting secure integration of HIQuad X with HIMax, HIMatrix systems, and RIO (Remote I/O);

Integrate HIPRO-S V2 protocol to establish secure connections with existing HIQuad F 8627X systems, ensuring compatibility during upgrades of older systems;

Support PADT (Programming and Debugging Tool) to communicate with the system through SILworX, enabling program download and diagnosis.

Classification of supported communication protocols

The communication protocols of HIQuad X are divided into "safety related protocols" and "standard protocols", which are implemented through different modules:

Protocol type supports the core purpose of protocol implementation module

Secure communication protocols SafeEthernet, HIPRO-S V2, SNTP (time synchronization) F-CPU 01/F-COM 01 for secure data transmission, time synchronization, and interconnection with legacy HIQuad systems

Standard communication protocols Modbus TCP (master/slave), Profibus DP (slave), Modbus RTU (master/slave), COM User Task (CUT, custom protocol programming) F-COM 01 and third-party devices such as SCADA systems HMI、 Non safety data exchange of smart meters

Compliance and Certification Standards

HIQuad X complies with multiple international safety and industrial standards, ensuring compliant applications in different regions and industries worldwide. Core certifications include:

Safety integrity standards: IEC 61508 (maximum SIL 3), IEC 61511 (maximum SIL 3 for process industries), EN ISO 13849-1 (maximum PL e);

Industry specific standards: EN 50156 (railway applications), EN 298 (burner control), EN 12067 (oil and gas pipelines), EN 54-2 (fire detection and alarm), NFPA 72/85/86 (North American fire and boiler standards);

Explosion proof standard: EN 60079-15 (ATEX Zone 2, non explosion proof area);

Network security standard: IEC 62443 (SL1, to be published).

Summary

As an upgraded version of the HIMA safety system, the core value of HIQuad X lies in * * "balancing safety and availability, upgrading and compatibility" * *: it not only meets the highest SIL 3 safety level requirements, but also improves system availability through flexible architecture, fast reloading, and optimized diagnostics; Simultaneously compatible with existing HIQuad I/O modules and communication protocols, significantly reducing the cost of upgrading old systems, suitable for various industrial scenarios that require high safety and efficiency.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands