HIMA HIQuad X Safety System

HIMA HIQuad X Safety System

System Overview and Positioning

HIQuad X is a programmable electronic safety system launched by HIMA. As an upgraded version of the HIQuad system with over 30 years of application history, it integrates mature HIQuad I/O technology and high-performance HIMax system architecture, suitable for scenarios with strict safety requirements and the need to ensure system availability (such as process industries and energy fields). The system supports centralized and distributed deployment, and is compatible with various I/O modules including intrinsically safe SIL 3 modules. It is programmed using SILworX engineering tools to meet safety function requirements such as "de energize to trip" and "energize to trip".

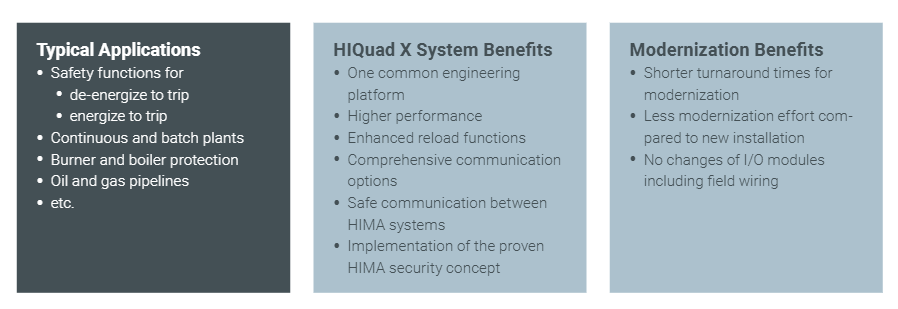

Typical application scenarios

HIQuad X is mainly aimed at process industries and safety critical fields, with typical applications including:

Continuous and batch production equipment: safety interlock control for chemical reaction vessels and pharmaceutical production lines;

Burner and boiler protection: realize safety functions such as flame monitoring, emergency shutdown due to overheating and overpressure;

Oil and gas pipelines: pressure and flow anomaly detection and emergency cutoff control;

Other industrial scenarios that require compliance with SIL 3 safety level, such as nuclear power auxiliary systems and safety monitoring in petrochemical storage tank areas.

Core advantages

(1) System level advantages

Improvement of engineering and operation efficiency

Adopting the Unified Engineering Platform (SILworX) to reduce the cost of switching between multiple tools;

Support fast reload of application programs, hardware configurations, and communication parameters to shorten fault recovery time;

Optimize diagnostic functions (such as real-time monitoring of module status and fault location prompts) to reduce maintenance and troubleshooting difficulties.

Performance and flexibility optimization

Shorten the system cycle times and improve real-time control response speed;

Accelerate REAL data computation efficiency to meet high-precision process control requirements;

Supporting a hybrid architecture of single loop (Mono) and redundant loop, flexibly adapting to different availability requirements, and reducing device footprint;

Supports multitasking and can run up to 32 applications simultaneously, meeting the requirements for complex control logic splitting.

Security and compatibility guarantee

Continuing HIMA's mature safety concept and meeting the highest SIL 3 safety level requirements;

Compatible with 24 existing HIQuad I/O modules, no need to replace I/O hardware or field wiring during upgrades, reducing renovation costs and downtime;

F-CPU 01 operates without interference with the I/O module, avoiding mutual influence between core control and signal acquisition;

Cross connection between modules is supported to enhance system redundancy and availability.

(2) Highlights of modernization upgrade

Compared to traditional systems, HIQuad X has significant advantages in upgrade scenarios:

Shorter transformation cycle: No need to redeploy I/O wiring, reducing on-site construction workload;

High hardware reuse rate: directly compatible with existing HIQuad I/O modules, reducing upgrade costs;

Enhanced scalability: supports longer system buses, better electromagnetic compatibility (EMC stability), and adapts to complex industrial environments;

Optimization of operating experience: Improved tactile feedback design (such as module insertion and removal feel, button operation feedback) enhances operational convenience.

System architecture and core parameters

(1) Differences between two major system models

The HIQuad X is divided into two models, H51X and H41X, with core configuration differences as shown in the table below:

Model: Maximum I/O Expansion Rack Number, Single System: Maximum I/O Module Number, Applicable Scenarios

H51X 16 with 256 large complex systems (such as large petrochemical parks and centralized control of multiple units)

H41X 1 set of 28 small and medium-sized systems (such as single production line, independent equipment safety control)

(2) Key components and functions

Component model type, core functions and parameters

The F-CPU 01 processor module is suitable for H51X/H41X, including 2 RJ-45 interfaces, supporting SIL 3 safety level, and implementing core control logic operations

The F-COM 01 communication module integrates Ethernet, Profibus DP, and serial communication functions, including 2 RJ-45 interfaces and 1 9-pin D-Sub interface (including 2 RS 485 channels), supporting both secure and standard protocols

F-IOP 01 I/O processing module SIL 3 level, with redundant system bus, responsible for I/O signal acquisition and control instruction execution

F-PWR 01 power module outputs 24 VDC/5 VDC, with a power of 50 W, suitable for the main power supply of H41X/H51X systems

F-PWR 02 (optional) watchdog power module is only suitable for H51X expansion rack, ensuring stable power supply for expansion units

F-BASE RACK 01 basic rack 19 inch specification, 4U height, suitable for H51X system

F-BASE RACK 02 basic rack 19 inch specification, 4U height, including 12 I/O module slots, suitable for H41X system

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands