Allen-Bradley IMC ™ S Class Compact Motion Controllers (IMC-S/23x model)

Allen-Bradley IMC ™ S Class Compact Motion Controllers (IMC-S/23x model)

Core positioning and basic functions of the product

IMC-S/23x is a compact, robust microprocessor based motion controller under Rockwell Automation Allen Bradley, supporting 2-axis or 4-axis servo control, integrating logic and field power, and can be used as an independent motion and logic controller without additional accessories, suitable for various industrial scenarios. Its core function revolves around closed-loop motion control, which requires external drive systems and feedback encoders to achieve various high-precision motion controls, including:

Single point positioning control: supports three speed profiles: trapezoidal, parabolic, and S-shaped, and can independently program speed, acceleration, and deceleration parameters to meet smooth start stop requirements under different operating conditions.

Multi axis interpolation function: Supports up to 3-axis linkage, achieving linear, circular, and spiral interpolation, suitable for complex trajectory motion scenes (such as precision machining path control).

Synchronous control capability: equipped with electronic gear and electronic cam functions, the electronic gear can make any shaft follow the main axis in a programmable proportion (proportion supports floating point or fractional form); Electronic cam can generate collaborative motion profiles based on time or main axis position, and can also be combined with phase shift, automatic positioning, and automatic correction functions to simplify complex synchronous motion programming.

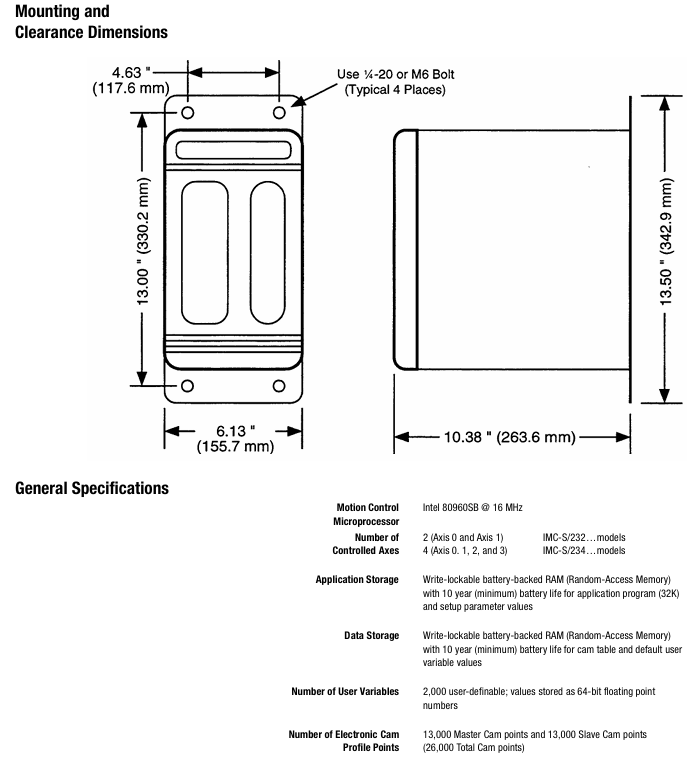

Hardware configuration and specifications

(1) Core hardware parameters

Category specific parameters

The microprocessor Intel 80960SB operates at a frequency of 16MHz and adopts RISC architecture to ensure high-speed data processing and motion computing

Axis configuration includes 2 axes (IMC-S/232 model) and 4 axes (IMC-S/234 model)

Feedback and output encoder input supports incremental AB orthogonal signals, with a maximum feedback count rate of 4MHz, ensuring accuracy under high-speed motion; The servo output is an isolated 16 bit DAC, supporting ± 10V voltage or ± 150mA current mode, and can be independently configured by axis

Storage configuration applications and parameter storage use RAM (non-volatile) with battery backup, with a battery life of at least 10 years; Can store 32K applications, 13000 main cam points+13000 slave cam points, support 2000 64 bit floating-point user variables

Environmental adaptability: Operating temperature range of 0-50 ℃, storage temperature range of -40-70 ℃, maximum humidity of 95% (non condensing), suitable for complex industrial environments

Power requirements: AC input 90-132V/175-264V (47-63Hz, maximum 3A), I/O power supply 5-40V DC (nominal 24V DC, maximum 3A), all equipped with 3A slow melting fuse protection

(2) I/O interface configuration

The dedicated discrete I/O: 2-axis model includes 10 inputs (5 per axis, corresponding to origin switch, positive and negative overtravel switch, driver fault, position positioning signal) and 4 outputs (2 per axis, corresponding to driver enable, absolute position trigger); The 4-axis model has 20 inputs and 8 outputs, all of which are designed with optical isolation. The output includes relay contacts (driver enabled) and solid-state relays (position triggered).

Extended I/O support: can directly connect up to 8 Allen Bradley Flex devices ™ I/O module, with a total of 128 discrete I/O points, can also be replaced with analog I/O modules (such as 8-channel analog input and 4-channel analog output modules) to meet different signal acquisition and control requirements, and can be directly connected without the need for additional adapters for use.

Software and Programming

(1) Programming environment

Using Allen Bradley's proprietary GML (Graphic Motion Control Language) for application programming, providing over 100 instructions and allowing for complete customization of controller functions; Equipped with a graphical development system, it supports real-time debugging, reduces programming difficulty, and supports multitasking operating systems. It can execute up to 10 tasks simultaneously, improving system efficiency.

(2) Program Download and Storage

Download programs to the controller through RS-232C or RS-422 ports, store them in non-volatile RAM, and have a "Memory Lock" key switch on the panel to prevent accidental operation or unauthorized modification of programs and parameters.

Communication function

The controller is equipped with multi-channel communication interfaces, supporting flexible interconnection with external devices, including:

Serial communication: 2 serial ports (A/B), can be independently configured as RS-232C or RS-422 (optical isolation), RS-232C has a maximum baud rate of 19.2k, RS-422 has a maximum baud rate of 128k; port B can be replaced with DH-485 channel (half duplex, baud rate of 9.6k/19.2k, RJ-45 interface), used for human-machine interface (MMI) connection, supports ASCII encoding and XON/XOFF flow control.

Remote I/O option (IMC-S/23x-R model): Supports remote I/O communication with other Allen Bradley devices (such as PLCs), supports discrete signal and block transmission, with a maximum block transmission length of 64 words (128 bytes), and supports multiple data formats such as 32-bit integers and 32-bit floating-point numbers; The rack address can be selected between 0-31, and the rack width supports 1/4, 1/2, 3/4, and full rack configurations, corresponding to different I/O points (such as a full rack with 100 inputs and 100 outputs).

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands