ABB IRC5 Industrial Robot Controller

ABB IRC5 Industrial Robot Controller

Core advantages and positioning

As a product based on ABB's over 40 years of experience in robotics technology, IRC5 is centered around unique motion control technology, which combines flexibility, safety, modular design, customizable user interface, multi robot control, and PC tool support, setting an industry benchmark for industrial robot applications.

Key Features

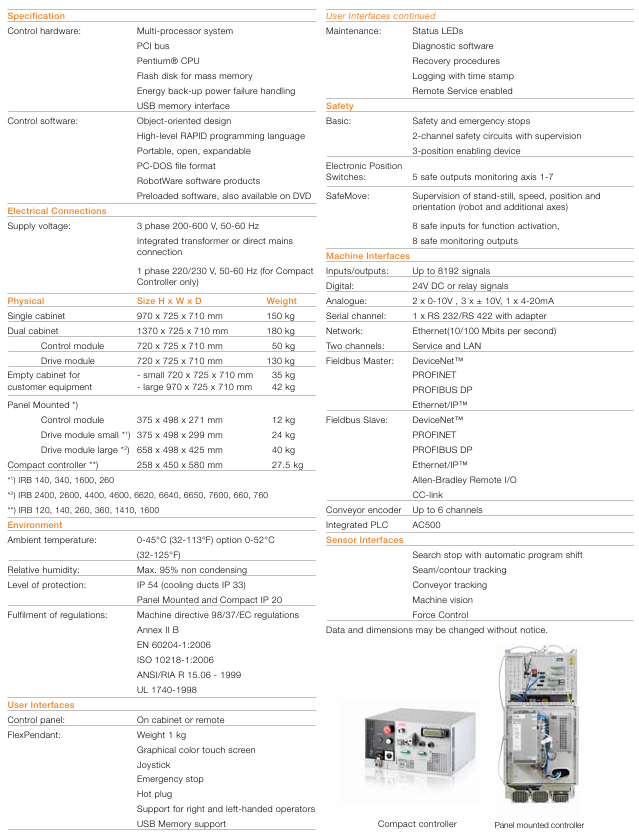

Security: Passed third-party certification and complies with all relevant regulations. Equipped with electronic position switches and SafeMove safety systems, it achieves a new generation of safety protection and supports more flexible cell safety solutions (such as robot operator cooperation). Basic safety functions include safety emergency stop, dual channel safety circuit monitoring, and three position enabling devices.

Motion control: Based on advanced dynamic modeling, QuickMove achieves the shortest physical cycle time, TrueMove ensures precise path accuracy, and the path is independent of speed, automatically presenting predictable high-performance performance without the need for programmer debugging.

Modular design: Provides multiple variants to meet different needs, modules can be stacked, placed side by side, or distributed, optimizing footprint and cell layout. Including compact models (controlling low-end IRB series robots) and panel mounted models (inorganic cabinets, suitable for special environments).

Operation and programming: The FlexPendant interface adopts a color touch screen and 3D joystick, supporting customized applications; The RAPID programming language combines simplicity, flexibility, and powerful functionality, supporting structured programs, workshop languages, and various process applications.

Communication capability: Supports advanced I/O fieldbus and is a good node in the factory network, with functions such as sensor interface, remote disk access, socket communication, etc. Ethernet supports 10/100 Mbps, including service and LAN dual channels.

Remote services and tools: can be remotely monitored through GSM or Ethernet, providing advanced diagnostic, backup management, reporting, and preventive maintenance services; The RobotStudio tool supports online and offline processing of IRC5 data, with offline mode providing digital copies of the robot system and powerful programming and simulation capabilities.

MultiMove: A controller can control up to 4 robots, and for each additional robot, a compact drive module needs to be added to perfectly coordinate complex motion patterns.

Technical parameters

Maintenance: including status indicator lights, diagnostic software, recovery program, timestamp logging, and remote service functionality.

I/O signals: up to 8192, digital signals support 24V DC or relay signals, analog signals include 2 × 0-10V, 3 × ± 10V, 1 × 4-20mA, etc.

Fieldbus: Both master-slave modes support DeviceNet ™、 PROFINET、PROFIBUS DP、Ethernet/IP ™ It also supports Allen Bradley Remote I/O, CC link, and up to 6 channels of conveyor encoders, among other types.

Integrated PLC: AC500.

Sensor interface: supports search stop and automatic program displacement, weld/contour tracking, conveyor belt tracking, machine vision, force control, etc.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands