Selection and Application of KOLLMORGEN E/H Series Stepper Motor

Kollmorgen E/H series stepper motors: an engineering solution for high performance and reliability

Introduction: Excellent partner in the field of motion control

In today's highly automated industrial environment, precise, reliable, and efficient motion control solutions have become the core competitiveness of machine design and manufacturing. As a global leader in the field of motion control systems, Kollmorgen, with over a century of technological accumulation and innovative spirit, continues to provide breakthrough products and solutions for various industries. Its product footprint covers extreme and precision application scenarios ranging from Mars exploration, spacecraft, surgical robots to industrial production lines, confirming its extraordinary strength in the field of high-performance motion control. This article aims to provide a comprehensive and professional reference guide for engineers and machine designers by deeply analyzing the E/H series stepper motors under Kollmorgen, from their design concepts, core technologies, detailed specifications to actual selection and application.

Overview of E/H series stepper motors: core characteristics and design philosophy

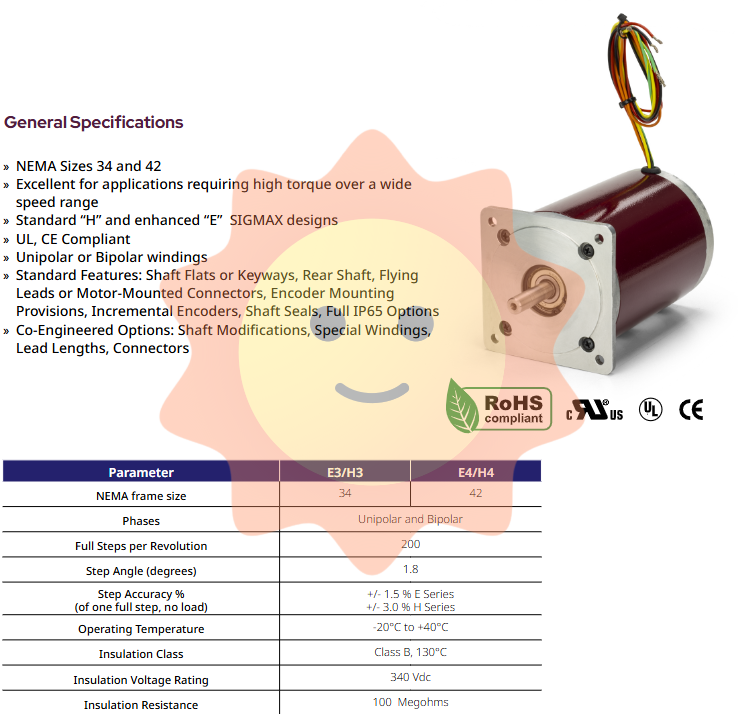

The E/H series stepper motors are the core product line launched by Kollmorgen for general and high-performance application needs. This series adopts a traditional circular chassis design and offers two standard frame sizes, NEMA 34 (90mm) and NEMA 42 (110mm), covering a wide range of installation compatibility. Its maximum holding torque can reach 27.95 N · m (3958 oz in), which can meet the requirements of most industrial applications for high dynamic response and strong positioning force.

The core highlight of this series lies in its high customizability and technological differentiation:

Dual Series Design: The series includes the standard "H" series and the performance enhanced "E" series. The E series exclusively uses Kollmorgen's SIGMAX ™ Through optimization in motor design, technology has achieved higher torque output and faster acceleration capability, making it particularly suitable for applications that require high-speed reciprocating motion or rapid positioning.

Wide range of connection and packaging options: Users can flexibly choose terminal board connections (via conduit), MS connectors, or fly wire lead out methods based on the on-site installation environment and electrical layout. In terms of protection level, NEMA 34 and 42 models can achieve IP65 protection level when using "C" (MS connector), "L" (terminal board) or "M" (terminal board) structure and equipped with shaft seals, effectively preventing dust and low-pressure water jets, and adapting to harsh industrial environments.

Excellent reliability certification: The entire series of motors have obtained UL certification and use B-class insulation (130 ° C) to ensure long-term stable operation and electrical safety within the working temperature range of -20 ° C to+40 ° C.

In depth technical specifications: the cornerstone of building a reliable system

The general technical specifications of E/H series motors lay the foundation for their stable performance. The entire series offers Unipolar and Bipolar winding options, providing flexibility for users to match different types of drivers. The standard step angle of the motor is 1.8 °, with 200 full steps per revolution. In terms of accuracy, the E series demonstrates higher positioning consistency, with a step accuracy (unloaded) of ± 1.5%, while the H series is ± 3.0%, making the E series more advantageous in applications that require extremely high positioning repeatability accuracy.

The electrical insulation performance of the motor is also excellent, with a rated insulation voltage of 340 Vdc and an insulation resistance of up to 100 M Ω, providing a solid guarantee for the safe operation of the system in complex electrical environments. These rigorous specification parameters ensure that the E/H series motors can stably serve in industries with strict requirements for motion control quality, such as printing and packaging, food and beverage processing, medical equipment, laboratory automation, material forming and cutting.

Detailed selection guide: from requirements to models

Kollmorgen provides a clear selection path for the E/H series. For users familiar with the product, they can directly refer to the Model Nomenclature to confirm the part number. The naming convention is a system containing multi digit codes that define in detail the series (E/H), frame size, stack length, installation method, shaft configuration, winding type, shaft modification, encoder options, customization content, rotor type, lead connection method, and structural type of the motor. For example, a motor model "E33HCHP - LEK-M2-01" contains all the information from the motor series to the specific connection method.

For new users, it is recommended to follow the following steps:

Determine basic requirements: First, determine the NEMA frame size (34 or 42) and approximate torque range based on load, speed, accuracy, and installation space requirements.

Refer to the general specifications: Understand the basic electrical parameters, insulation level, protection capability, etc. of the motor to ensure compliance with the application environment.

Analyze performance data: Conduct in-depth research on detailed performance tables for different stack lengths (1 stack, 2 stacks, 3 stacks, 4 stacks) and winding configurations (parallel, series, single pole). These tables provide key data including holding torque, rated phase current, phase resistance, phase inductance, thermal resistance, rotor inertia, weight, and shaft load (radial and axial forces). For example, the torque range of the E3/H3 1-stack motor ranges from approximately 1.58 Nm to 1.71 Nm, while the 4-stack enhanced (E34 series) motor can provide a holding torque of up to 9.18 Nm.

Reference mechanical drawings: The document provides detailed dimensional drawings for the E3/H3 and E4/H4 series, including standard front-end covers, heavy-duty front-end covers, splash proof structures, and various external dimensions with MS connectors and encoder options. The user needs to confirm whether the installation hole position, shaft extension size (standard keyway, flat or rear shaft extension, etc.), and total length comply with the mechanical design.

Build part number: Based on all determined technical parameters and options, construct a complete motor model according to naming conventions.

Electrical connection and encoder integration: achieving precise control

To achieve correct docking with the driver, the document elaborates on the wiring methods for different winding configurations:

4-wire bipolar connection (parallel and series): Corresponding lead colors, terminal numbers, and MS connector pin definitions are provided to guide users in achieving the most efficient current drive mode.

6-wire single pole connection: clarifies the connection method of the center tap, suitable for single pole drivers.

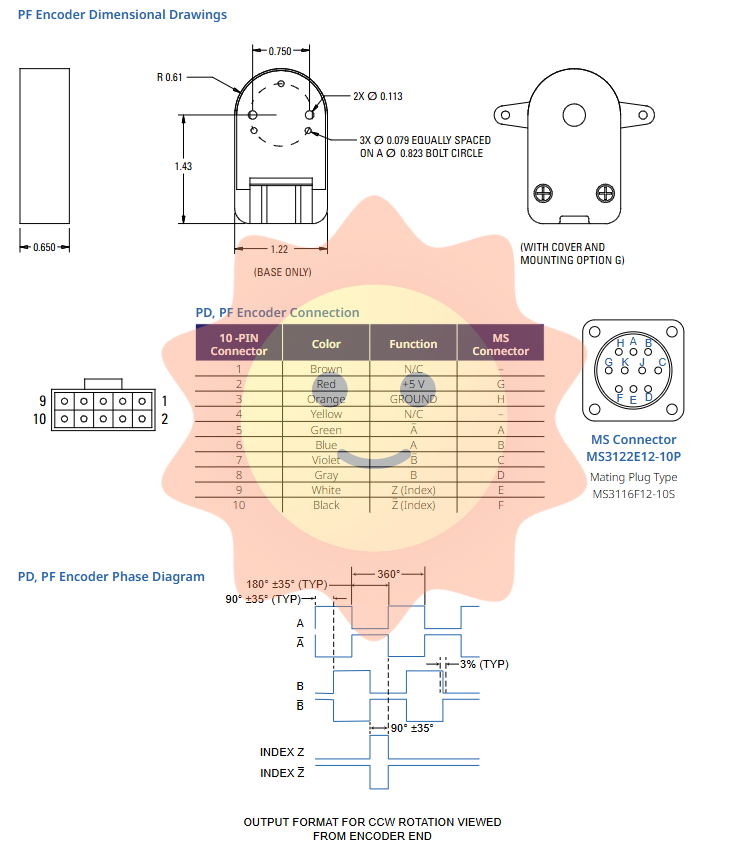

For applications that require closed-loop feedback or higher positioning accuracy, the E/H series offers optional incremental optical encoders. There are mainly two types of encoder options: PD type (500 wires/rpm) and PF type (1000 wires/rpm). They all use differential line drive outputs, providing dual channel orthogonal signals and index (Z) signals, with a maximum response frequency of 100 kHz and a wide operating temperature range of -40 ° C to 100 ° C. The encoder is integrated through a 10 pin connector (matched with MS3116F12-10S plug), with clear wiring definitions for system integration. The installation of encoders provides the possibility to improve system accuracy, achieve out of step detection, and more complex motion control algorithms.

Application areas and value realization

The design of Kollmorgen E/H series stepper motors enables them to serve numerous high-end and general industrial fields. Its application in the aerospace and defense fields reflects the requirement for ultimate reliability; Accuracy and cleanliness compatibility are crucial in medical imaging, in vitro diagnostics, and laboratory automation equipment; In the printing, packaging, and food processing industries, high speed and high reliability are directly related to production efficiency and cost; In emerging warehouse automation (including AGV systems) and robotics technologies, their high torque and customizability provide support for flexible design.

The core value of choosing E/H series motors lies in their direct contribution to enhancing overall equipment efficiency (OEE) for users by improving machine performance, enhancing reliability, improving energy efficiency, and ensuring operational safety, thereby creating significant differentiation advantages for machine manufacturers in fierce market competition. Kollmorgen's global engineering, service, and support network, as well as its world-class engineering design expertise and self-service design tools, further ensure the full cycle success of users from selection, integration to maintenance.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands