KOLLMORGEN IDC EC Series Electric Cylinder Configuration and Application Guide

IDC EC series electric cylinder: modular engineering solution for precision linear motion control

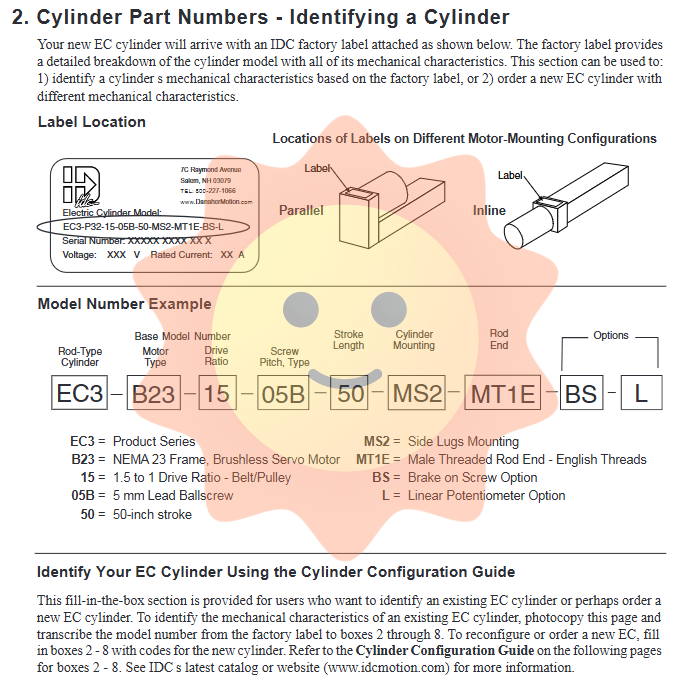

In the fields of industrial automation, scientific experiments, and high-end commercial equipment, precise control of linear thrust, speed, and position is the core indicator for measuring system performance. The EC series electric cylinder launched by IDC (Intelligent Dynamic Control) is a high-performance linear actuator designed to meet this high standard requirement. From compact EC2 to heavy-duty EC5, this series of products integrates advanced mechanical design, flexible configuration options, and strict environmental adaptability, providing machine designers with a reliable, precise, and highly customizable power solution. This article will delve into the technical architecture, configuration logic, installation specifications, maintenance points, and value of the EC series electric cylinder in complex application scenarios, providing comprehensive application guidelines for engineers and integrators.

Product Core Architecture and Modular Design Philosophy

The core design of the EC series electric cylinder abandons the complex pipelines and pollution problems of traditional pneumatic or hydraulic cylinders, and uses an electric motor to directly drive the screw through an efficient transmission system, achieving clean, quiet, and controllable linear motion. Its typical structure from top to bottom includes: drive motor (which can be provided by the customer), drive housing, transmission system (belt drive or gear drive), thrust bearing, screw (ball screw or trapezoidal screw), drive nut, internal guide flange, rod end bearing, dust scraping sealing ring, thrust tube, and guide cylinder. This integrated design ensures efficient power transmission and compact structure.

The outstanding advantage of this series lies in its high modularity and configurability. Users can select "menu style" options based on specific application load, speed, accuracy, and space requirements from the following dimensions:

Motor type: Supports multiple power sources, including 24V/160V DC brushed motors, NEMA 23/34/42 frame stepper motors (such as P22, P32, S32, S42), and high-performance brushless servo motors (B23, B32, B41). Even supports the "X" option, allowing users to install their own provided motors, greatly enhancing system compatibility.

Drive ratio: Provides multiple transmission ratios (such as 10, 15, 20, 50, 70, 100, 10L) from 1:1 direct coupling to 10:1 worm gear reduction, allowing users to achieve the best balance between high speed and high thrust.

Screw type and lead: EC2 and EC3 can choose precision rolled ball screws (05B, 10B, 16B) or trapezoidal screws (04A); EC4 and EC5 provide larger lead ball screws (10B, 25B, 32B). Different leads directly affect motion speed and resolution.

Travel length: Provides standard travel ranging from 50 millimeters to 1500 millimeters, and can accept customized travel in increments of 1 millimeter to meet various travel needs.

Installation and connection methods: Multiple cylinder installation methods (such as front flange MF1, rear flange MF2, side ear MS2, fork ear MP2, journal MT4, etc.) and rod end connection forms (such as internal/external thread FT1/MT1, fork FC2, ball head FS2) are provided to adapt to different mechanical interfaces and compensate for misalignment requirements.

In addition, all standard models meet the IP54 protection level and can choose the IP65 protective cover option (- PB) to protect the thrust tube/sealing ring interface from dust and water spray intrusion. Its metric dimensions comply with the ISO 6431 standard, meeting the needs of global equipment manufacturing.

Performance specifications and configuration references: matching application requirements

The performance parameters of each model in the EC series (EC2, EC3, EC4, EC5) have their own emphasis to meet different loads and dynamic requirements. For example:

EC3: When paired with brushless servo motors (B23/B32), the maximum no-load speed can reach 1280 mm/s, the repeat positioning accuracy is as high as ± 0.013 mm, and the maximum load capacity is 7200 N, suitable for high-speed and high-precision applications.

EC2: As a more economical entry-level option, its DC brushed motor (D series) version has a maximum load of 3230 N, while the stepper or servo version has a load of 3600 N.

EC4 and EC5: For heavy-duty applications, EC5, when paired with a brushless servo motor, has a maximum load capacity of up to 25000 N (approximately 5620 lbs), demonstrating strong thrust performance.

When selecting, users must carefully check the "performance curve" and specification table in the product manual to ensure that the speed thrust characteristics of the motor match the critical speed and cylindrical load limit of the screw, in order to avoid equipment damage caused by resonance or screw buckling.

Professional Installation Guide: Ensure Long term Reliable Operation

Correct installation is the foundation for ensuring the performance and lifespan of electric cylinders. The IDC manual provides detailed installation specifications, with core points including:

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands