Kollmorgen S300 Servo Drive Application Guide

Wiring and application: The STO Enable input must be connected to the output of a safety relay or safety controller that meets the same safety level (such as PLd/SIL 2). If STO is not required, the X4/5 terminal must be directly connected to+24V DC, and the driver cannot be used as a safety component that complies with the EU Machinery Directive.

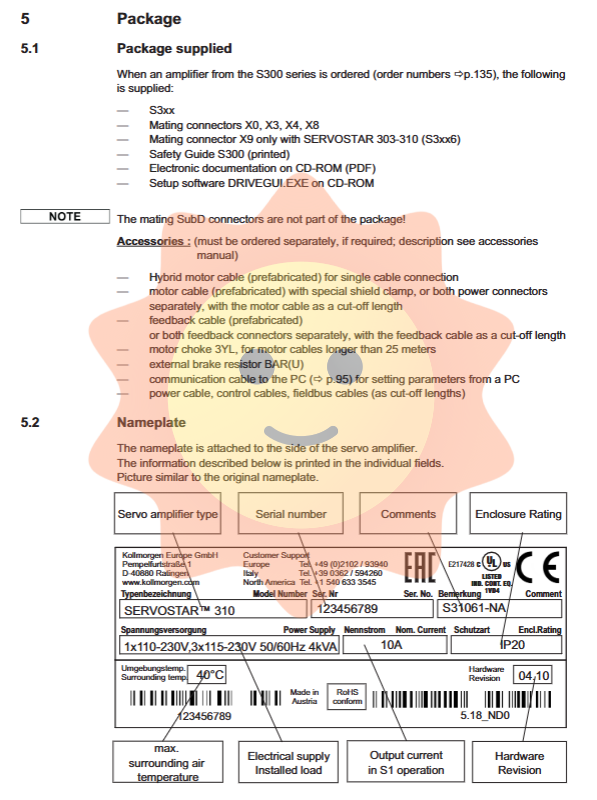

Detailed technical specifications and mechanical and electrical installation

1. Summary of Key Technical Data:

Switching frequency: The output stage defaults to 8kHz, and can switch to 16kHz when the current is halved.

Environmental conditions: The operating environment temperature ranges from 0 ° C to+40 ° C (rated conditions), with a maximum of+55 ° C (requiring derating for use). The protection level is IP20 and it needs to be installed inside the control cabinet.

Connector and torque: It is recommended to use 2.5mm ² (230V type) or 4mm ² (480V type) cables for power terminals (X0, X8, X9), with a tightening torque of 0.5-0.6 Nm. Use thinner cables for signal terminals.

Fuse protection: Users need to provide external fuses, for example, S303/341 recommends 6A delay type (T), S306/346 recommends 10A.

2. Key points for mechanical installation:

The driver should be installed vertically to facilitate heat dissipation.

Ensure that the installation base plate has good conductivity and do not use spray painted (non-conductive) installation plates to achieve effective EMC grounding.

Adequate cooling must be ensured inside the cabinet, and the inlet air temperature must be below 40 ° C. Some models rely on natural convection, while others require fans (some are optional controlled fans).

Avoid installing equipment that generates strong magnetic fields in close proximity to the driver.

3. Electrical installation specifications:

Cable separation: Power cables and signal control cables must be laid separately, with a recommended minimum distance of 200mm to enhance anti-interference performance.

Shielding layer grounding: All shielding layers (motor cables, encoder cables, etc.) should be extensively and low impedance grounded at both ends of the driver and motor terminals, usually using the shielding busbar on the front cover plate of the driver.

Grounding system: Pay attention to distinguishing between AGND (analog ground, used for encoders and analog inputs) and DGND (digital ground, used for 24V I/O). The two are optically isolated inside the driver.

Motor connection: When the length of the motor cable exceeds 25 meters, a motor reactor (such as 3YL) must be used to limit leakage current and voltage reflection, and protect the output stage of the driver.

Rich feedback system and interface configuration

The S300 supports almost all series of motor feedback devices, which is an important manifestation of its flexibility.

1. Single cable connection (SFD3/HiperFACE DSL):

This is the most advanced connection method that integrates the power line and the digital feedback signal of the high-resolution absolute encoder into a hybrid cable, greatly simplifying wiring and improving reliability. The maximum cable length is 25 meters.

2. Dual cable connection (power and feedback separated):

Support multiple types of feedback, users need to set the FBTYPE parameter in the debugging software (DRIVE GUI) to correspond:

Rotary transformer: connected to X2, simple and reliable, with strong resistance to harsh environments.

Sine encoder: supports multiple digital protocols such as EnDat 2.1/2.2, Hiperface, BiSS (analog/digital), SSI, etc., providing high-precision absolute position information.

Incremental encoder: Supports 5V (A/B/Z) and 24V types, connected to X1, X3, or X5.

Hall sensor: used for commutation of brushless motors.

3. Encoder simulation output:

The driver can provide incremental (A quad B) or SSI format position output signals through the X5 terminal, facilitating the transmission of motor position to the higher-level control system or other drivers, achieving master-slave tracking.

Debugging, software tools, and fault diagnosis

1. Debugging software (DRIVE GUI. EXE):

This is the core tool for configuring S300, running on the Windows system. It provides a graphical interface that supports online parameter settings, real-time monitoring, oscilloscope functionality, Bode plot analysis, and automatic tuning.

Quick Start Wizard: Guide users to complete motor model selection (which can be loaded from the database), feedback type setting, basic unit conversion, and preliminary controller tuning.

Complete configuration: Provides deep access to current loop, speed loop, position loop parameters, digital/analog I/O function allocation, electronic gear ratio, motion task programming, and more.

2. Status display and button operation:

The front of the driver is equipped with a three digit LED display screen and two buttons, which can display status codes, error/warning codes, and perform basic parameter viewing and site address settings.

3. Common troubleshooting:

Communication failure: Check the null mode cable, PC interface selection, and 24V auxiliary power supply for the driver.

Motor not turning: Check if the ENABLE (X3/12) and STO Enable (X4/5) signals are both+24V, if the software enable is activated, if the motor phase sequence is correct, and if the brake is released.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands