Emerson DeltaV M Series Virtual I/O Module 2 (VIM2)

Modular and flexible installation: Adopting the same installation method as the DeltaV controller, it can be installed in the controller slot of a 2-wide horizontal carrier or a 4-wide vertical carrier (located on the left side of the DeltaV controller), using standard DeltaV power supply. The design is durable and can operate stably for a long time.

Details of Function Implementation

(1) Implementation of I/O simulation function

Hardware coordination: The VIM2 hardware preloads the I/O simulation driver and communicates with the MiMiC software through the simulation network. After disconnecting the real I/O card from the control system, the MiMiC driver directly writes simulation signals to the I/O subsystem of the DeltaV controller.

Simulation data management: A single simulated process controller corresponds to one MiMiC dataset, and a MiMiMiC server can support up to 32 datasets (ports). Each dataset can accommodate 4000 MiMiMiC simulation labels, meeting the requirements of large-scale process simulation.

Technical Support: Technical support for I/O simulation drivers and MiMiC software is provided by MYNAH Technologies and requires separate contact with the supplier for service.

(2) Implementation of Ethernet I/O Integration Function

Drivers and configurations: Ethernet I/O drivers (such as Modbus TCP/IP master drivers, Ethernet/IP scanner drivers, etc.) need to be purchased separately from MYNAH. After loading the drivers, the DeltaV controller can automatically detect the debugged VIM2 (serial cards identified as slots 57-60 or 61-64 in single-mode configuration, and redundant pairs identified as slots 57-64 in redundant configuration).

Redundancy mechanism: The redundant VIM2 needs to be installed on independent 2-wide carriers, equipped with independent power supplies, and monitored for the status of the main and backup devices through dedicated redundant link cables (included in the redundancy kit) - the main VIM2 continuously communicates with industrial Ethernet devices, while the backup VIM2 sends intermittent signals to maintain communication integrity and ensure uninterrupted switching between the main and backup devices.

Configuration tool requirements: VIMNet Explorer needs to run on a workstation connected to the Ethernet I/O network (which can be a DeltaV workstation with a third network card or a non DeltaV workstation), support Windows XP/7 system, and complete connection configuration through the RJ45 Ethernet interface at the bottom of VIM2.

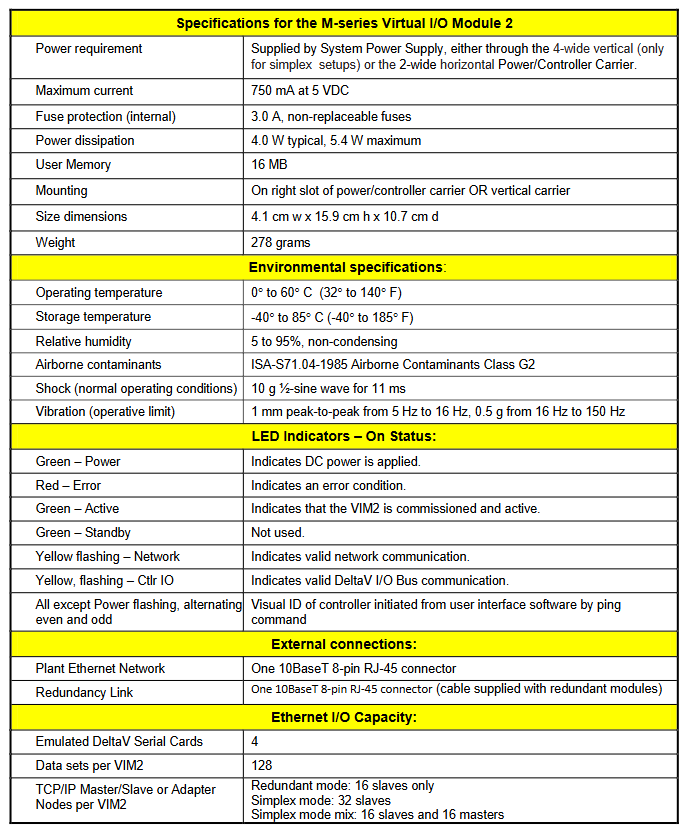

Hardware specifications

Category specific parameters

The power requirement is supplied by the DeltaV system power supply, supporting 2-wide horizontal carriers or 4-wide vertical carriers (single-mode configuration only)

Electrical protection built-in 3.0A non replaceable fuse, maximum current 750mA (5VDC)

Typical power consumption of 4.0W, maximum value of 5.4W

Storage and Size: User Memory 16MB; Size: 4.1cm (width) x 15.9cm (height) x 10.7cm (depth), Weight: 278g

Installation method: Install in the right slot (horizontal carrier) or vertical carrier of the power/controller carrier

Environmental parameters: Operating temperature: 0 ° C~60 ° C (32 ° F~140 ° F), Storage temperature: -40 ° C~85 ° C (-40 ° F~185 ° F); Relative humidity ranging from 5% to 95% (without condensation); The air pollutant level complies with ISA-S71.04-1985 G2 level; Shock resistance (normal operation): 10g half sine wave, continuous for 11ms; Vibration resistance (working limit): 1mm peak to peak value at 5Hz~16Hz, 0.5g at 16Hz~150Hz

LED indicator light - green (power): indicates connection to DC power supply

-Red (Error): Indicates the existence of an error status

-Green (Active): indicates that VIM2 has been debugged and is in an active state

-Green (Standby): Not used

-Yellow flashing (Network): indicates normal network communication

-Yellow flashing (Ctlr IO): indicates that DeltaV I/O bus communication is normal

-Alternating flashing (parity) except for the power light: device recognition triggered by the ping command on the user interface software

External Interface - Factory Ethernet: 1 10BaseT 8-pin RJ-45 connector

-Redundant link: 1 10BaseT 8-pin RJ-45 connector (redundant kit includes dedicated cable)

Ethernet I/O Capacity - Analog DeltaV Serial Card: 4

-Number of datasets: 128 per unit

-Number of device nodes: 32 single mode slave stations (or 16 master+16 slave stations), redundant 16 slave stations

DeltaV Authorization and Configuration Rules

DST counting rule: The DeltaV software authorization requirement (DST counting) for the VIM2 register is consistent with the serial card register - a single DeltaV serial card dataset can contain up to 100 values (Boolean, 8-bit/16 bit values), and if it is a floating-point or 32-bit value, it can contain up to 50 values; If a single dataset is referenced by only one module, it is counted as one DST; If referenced by multiple modules, the DST count is equal to the number of referenced modules.

DST type differentiation: The numerical count used to control the function block is "Control DST", and the numerical count used only for graphic display or historical data acquisition is SCADA value, not included in DST count.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands