STOBER POSIDRIVE ® How to install MDS 5000?

STOBER POSIDRIVE ® MDS 5000 installation method

Overview

This document is the fifth generation inverter product POSIDRIVE from STOBER company ® The installation manual for MDS 5000, version V 5.3 01/2008, covers core content such as safety instructions, technical parameters, mechanical installation, electrical installation, wiring allocation, connection examples, and accessories. It is suitable for professional technicians to install, debug, and maintain equipment, providing comprehensive guidance to ensure safe and stable operation of the equipment.

Safety instructions

(1) Definition of Security Level

Risk Description of Safety Signs

If you do not pay attention to this prompt, unexpected results or states may occur

CAUTION (no warning triangle) may cause property damage if appropriate preventive measures are not taken

CAUTION (with warning triangle) may cause minor personal injury and property damage if appropriate precautions are not taken

Warning: If appropriate preventive measures are not taken, there may be significant risks of death, serious personal injury, and significant property damage

If DANGER does not take appropriate preventive measures, it will inevitably result in life-threatening situations and significant property damage

NOTE: Important product information or document sections that require special attention

ACTION describes the particularly important steps in product operation

(2) Hardware security requirements

Device Attributes and Compliance: POSIDRIVE ® The FDS and MDS series are power electronic and electrical components used for energy flow regulation in high-voltage systems. They only supply power to servo motors (MDS) and asynchronous motors (FDS, MDS). Their use, installation, operation, and maintenance must comply with current regulations, legal requirements, applicable standards, and this technical document. They belong to the restricted sales category products specified in IEC 61800-3 and may cause high-frequency interference in residential areas. Users need to take appropriate measures.

High voltage safety: It is strictly prohibited to open the casing or disconnect the connection when the equipment is live; When installing or disassembling the option board, the device must be powered off (all power plugs disconnected) and wait for at least 5 minutes before operation; The equipment must be properly configured and installed in order to function properly. Transportation, installation, debugging, and operation are only allowed to be carried out by qualified personnel who have received specialized training.

Grounding and Protection: The equipment protection level is protective grounding, and the protective conductor must be connected according to regulations. It cannot operate directly on the IT network; Installation work can only be carried out in a power-off state. When working on the transmission system, it is necessary to lock the enable and disconnect the entire transmission system power supply (following 5 safety rules); Even without using DC link coupling, it is necessary to maintain its plug connection (BG0-BG2: X22); If the discharge time of the DC link capacitor exceeds 5 minutes, it is forbidden to insert any object into the interior of the equipment to avoid short circuits or equipment failures.

Environmental and installation regulations: When installing or performing other work inside the switchgear, the equipment must be protected from falling parts (such as wires, stranded wires, metal fragments, etc.); Before debugging, additional coverings need to be removed to prevent the equipment from overheating; The equipment needs to be installed inside the switchgear, and the ambient temperature should not exceed the specified technical parameter values; Only copper wire can be used, and the cross-sectional area of the wire must comply with the requirements of 60 ° C or 75 ° C in NEC standard 310-16 table.

Motor protection and circuit limitations: The motor must be equipped with an overall temperature monitor (basic insulation) that complies with EN 61800-5-1, or use external motor overload protection; The equipment is only suitable for power supply networks with a maximum symmetrical rated short-circuit current not exceeding 5000A (480V); Built in solid-state short-circuit protection does not provide branch circuit protection. Branch circuit protection should be provided according to the manufacturer's instructions, national electrical specifications, and local additional specifications. When using RK1 level fuses (see technical parameters section), it is suitable for circuits with a maximum root mean square symmetrical current of 10kA and 480V.

(3) Software Usage Specification

POSITool software permissions: This software package is used for application selection, parameter adjustment, and signal monitoring of STOBER fifth generation inverters. The copyright belongs to STOBER ANTRIEBSTECHNIK GmbH+Co. KG, and users are only authorized to use it. The software is only provided in machine-readable format; Customers who legally obtain the software may obtain non exclusive usage rights, which can be used for the above functions, and to support such use, make and install copies of the software (including one backup copy), all copies must retain copyright and other ownership notices.

Software usage restrictions: Customers are not allowed to use, copy, modify, transmit/transfer the software beyond the scope of the license, and are not allowed to perform reverse assembly, reverse compilation, or other conversion operations on the software. They are also not allowed to sublicense, rent, or lease the software.

Product maintenance scope: STOBER only assumes maintenance obligations for the last two current program versions prepared and released for use, and may choose to correct program errors or provide new versions; If the error cannot be corrected immediately, a temporary solution will be provided (which may require users to comply with special operating procedures); The right to correct errors can only be claimed when the reported errors are reproducible or can be recorded through machine output, and are reported in reproducible form and provide useful information for error correction; STOBER does not assume the obligation to correct errors in programs modified or tampered with by customers, unless the customer can prove that the error is not related to tampering; STOBER needs to store the current valid program version in a special protected location (fireproof data safe, bank vault).

Technical parameters

(1) Model Interpretation

Taking "MDS 5075/L" as an example, "MDS" is the product series, "5" represents the fifth generation, "075" represents a power of 7.5kW, "/L" represents the auxiliary voltage of the control electronic device as external 24V ("/H" represents the auxiliary voltage as DC link).

(2) General electrical parameters

Parameter Value

Under the rated maximum ambient air temperature data of 0-45 ° C, it can reach 55 ° C when the power is reduced by 2.5%/° C

Relative humidity during operation is 85%, with no condensation

Installation altitude below 1000m without restrictions, power reduction of 1.5%/100m from 1000-2000m

High voltage category complies with Class III of EN 61800-5-1

Pollution level meets level 2 of EN 60204/EN 50178

Protection level IP 20

The installation position is usually vertical installation

Ventilation method with built-in fan

Maximum voltage limit 830V

Brake chopper disabled voltage 740V/760V

(3) Detailed parameters of each specification and model

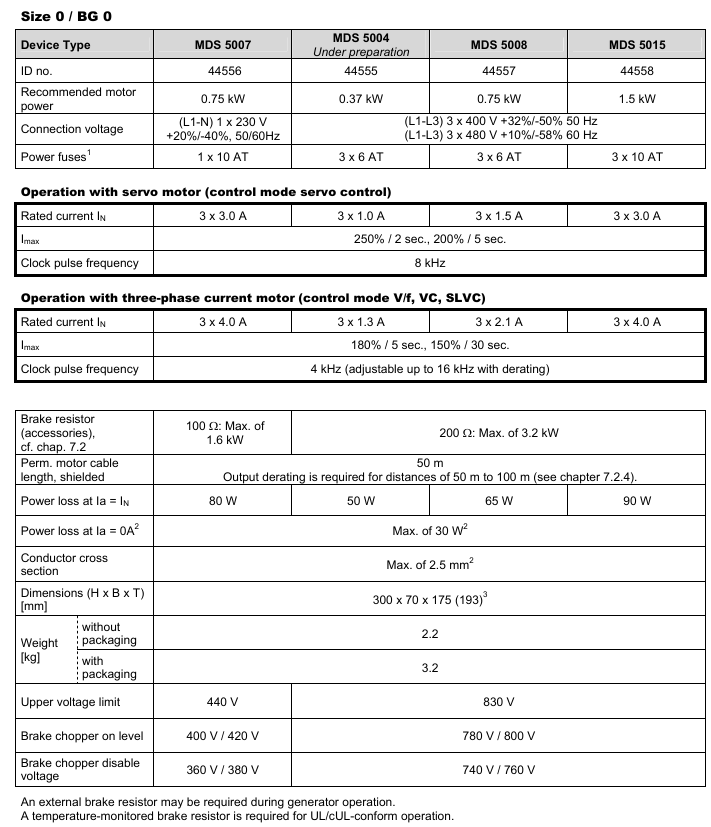

1. Specification 0/BG0

Equipment model MDS 5007 (ID: 44556) MDS 5004 (under preparation, ID:44555) MDS 5008(ID:44557) MDS 5015(ID:44558)

Recommended motor power 0.75kW 0.37kW 0.75kW 1.5kW

Connection voltage 1 × 230V (L1-N),+20%/-40%, 50/60Hz 3 × 400V (L1-L3),+32%/-50%, 50Hz; 3 × 480V (L1-L3),+10%/-58%, 60Hz Same as MDS 5004 Same as MDS 5004

Power fuse 1 × 10AT 3 × 6AT 3 × 6AT 3 × 10AT

Servo motor operation (servo control mode) - rated current (IN) 3 × 3.0A 3 × 1.0A 3 × 1.5A 3 × 3.0A

Servo motor operation (servo control mode) - maximum overload of 250%/2 seconds, 200%/5 seconds same as left, same as left

Servo Motor Operation (Servo Control Mode) - Clock Pulse Frequency 8kHz Same Left Same Left Same Left

Three phase current motor operation (V/f, VC, SLVC control mode) - rated current (IN) 3 × 4.0A 3 × 1.3A 3 × 2.1A 3 × 4.0A

Three phase current motor operation (V/f, VC, SLVC control mode) - maximum overload of 180%/5 seconds, 150%/30 seconds same as left, same as left, same as left

Three phase current motor operation (V/f, VC, SLVC control mode) - clock pulse frequency 4kHz (adjustable to 16kHz during derating) same as left, same as left, same as left

Braking resistor (accessories, see Chapter 7.2) 100 Ω: maximum 1.6kW, same as left 200 Ω: maximum 3.2kW, same as left

The allowed length of shielded motor cable is 50m, and the rating for 50-100m needs to be reduced (see Chapter 7.2.44). Same as left, same as left

When Ia=IN, the power consumption is 80W, 50W, 65W, and 90W

When Ia=0A, the maximum power consumption is 30W (depending on the connected option board and sensor, such as encoder), same as left, same as left

The maximum cross-sectional area of the wire is 2.5mm ², same left, same left, same left

Dimensions (H × B × T) [mm] 300 × 70 × 175 (193) (including depth of braking resistor RB 5000) Same as left, same as left

Weight [kg] (Unpackaged/Packaged) 2.2/3.2 Same Left Same Left Same Left

Maximum voltage limit 440V 830V Same Left Same Left

Brake chopper opening level 400V/420V 780V/800V same left same left

Brake chopper disable voltage 360V/380V 740V/760V same left same left

2. Specification 1/BG1

Parameter Value

Connection voltage 3 × 400V (L1-L3),+32%/-50%, 50Hz; 3×480V(L1-L3),+10%/-58%,60Hz

Power fuse 3 × 20AT

Servo motor operation (servo control mode) - rated current (IN) 3 × 10A

Servo motor operation (servo control mode) - maximum overload of 250%/2 seconds, 200%/5 seconds

Servo motor operation (servo control mode) - clock pulse frequency 8kHz

Three phase current motor operation (V/f, VC, SLVC control mode) - clock pulse frequency 4kHz (adjustable to 16kHz during derating)

Braking resistor (accessory) Ω: maximum 6.4kW

Power consumption (IN) 170W, 200W

Power consumption (Ia=0A) up to 30W (depending on the connected option board and sensor, such as encoder)

The maximum cross-sectional area of the wire is 4mm ²

Maximum voltage limit 830V

Brake chopper opening level 780V/800V

Brake chopper disabled voltage 740V/760V

3. Specification 2/BG2

Parameter Value

Connection voltage 3 × 400V (L1-L3),+32%/-50%, 50Hz; 3×480V(L1-L3),+10%/-58%,60Hz

Power fuse 3 × 50AT

Servo motor operation (servo control mode) - rated current (IN) 3 × 20A

Servo motor operation (servo control mode) - maximum overload of 250%/2 seconds, 200%/5 seconds

Servo motor operation (servo control mode) - clock pulse frequency 8kHz

Three phase current motor operation (V/f, VC, SLVC control mode) - clock pulse frequency 4kHz (adjustable to 16kHz during derating)

Braking resistor (accessory) 22 Ω: maximum 29kW

Power consumption (IN) 280W

Power consumption (Ia=0A) up to 30W (depending on the connected option board and sensor, such as encoder)

The maximum cross-sectional area of the wire is 6mm ²

Weight (unpackaged) 6.1kg

Maximum voltage limit 830V

Brake chopper opening level 780V/800V

Brake chopper disabled voltage 740V/760V

4. Specification 3/BG3

Equipment model MDS 5220 (ID: 44564) MDS 5370 (ID: 44566) MDS 5450 (ID: 44567)

Recommended motor power: 22kW, 37kW, 45kW

Connection voltage 3 × 400V (L1-L3),+32%/-50%, 50Hz; 3 × 480V (L1-L3),+10%/-58%, 60Hz same left same left

Power fuse 3 × 50AgG ² 3 × 80AgG ²-

Servo motor operation (servo control mode) - rated current (IN) 3 × 30A 3 × 50A 3 × 60A

Servo motor operation (servo control mode) - maximum overload of 250%/2 seconds, 200%/5 seconds ³ (average effective current within 10 minutes must not exceed rated current) Same left and same left

Servo Motor Operation (Servo Control Mode) - Clock Pulse Frequency 8kHz Same Left Same Left

Three phase current motor operation (V/f, VC, in preparation: SLVC control mode) - rated current (IN) 3 × 44A 3 × 70A 3 × 85A

Three phase current motor operation (V/f, VC, in preparation: SLVC control mode) - maximum overload of 180%/5 seconds, 150%/30 seconds ³ (average effective current within 10 minutes must not exceed rated current) same as left and right

Three phase current motor operation (V/f, VC, in preparation: SLVC control mode) - clock pulse frequency 4kHz (adjustable to 16kHz during derating) same left and same left

Internal braking resistor 30 Ω: 100W/maximum 21kW Same Left Same Left

External braking resistor (accessories, see Chapter 7.2) 15 Ω: maximum 42kW, same left, same left

Allowable shielded motor cable length of 100m, same left and same left

When Ia=IN, the power consumption is about 350W, about 600W, and about 1000W

When Ia=0A, the maximum power consumption is 55W ⁴ (depending on the connected option board and sensor, such as encoder). Same as left

When there is no core end sleeve in the cross-section of the wire, the maximum area is 35mm ², same left and same left

Dimensions (H × B × T) [mm] 382.5 × 190 × 276 Same Left Same Left

Weight [kg] (unpackaged/packaged) 11.8/13.6 13.2/15.0 13.2/15.0

The maximum voltage limit is 830V, same left and same left

The opening level of the brake chopper is 780V/800V, which is the same as the left

Brake chopper disable voltage 740V/760V same left same left

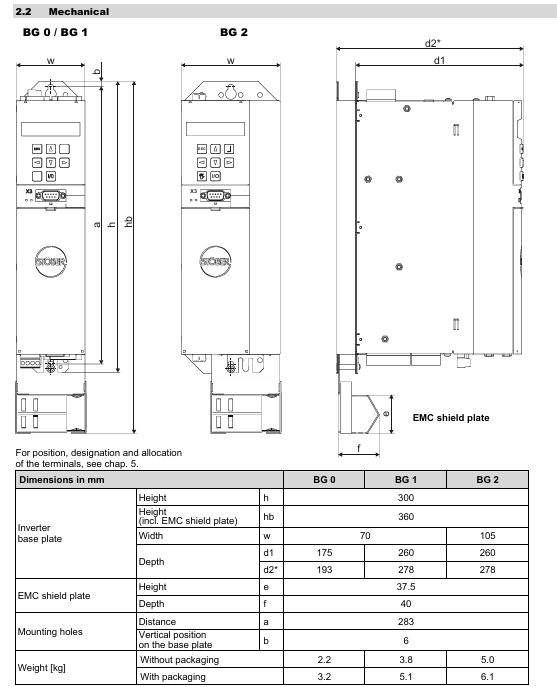

(4) Mechanical parameters

1. BG0/BG1/BG2

Parameter Value

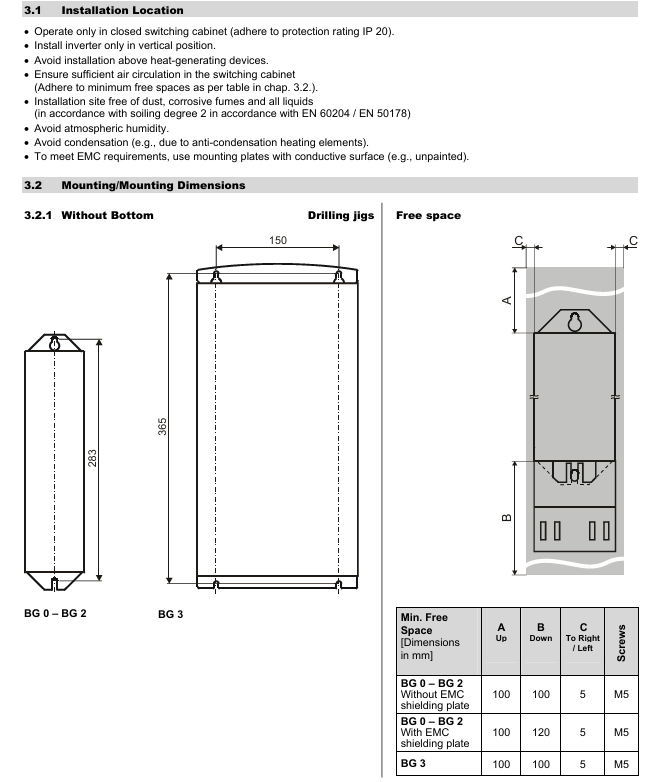

Minimum free space without EMC shielding board [mm] (up/down/right/left) 100/100/5/5

Minimum free space with EMC shielding board [mm] (up/down/right/left) 100/120/5/5

Screw specification M5

2. BG3

Parameter Value

Height [mm] 382.5

Inverter substrate width [mm] 190

Inverter substrate depth [mm] 276

Vertical distance [mm] 365

Number of vertical mounting holes on the substrate: 6

Horizontal distance [mm] 150

Minimum free space [mm] (up/down/right/left) 100/100/5/5

Screw specification M5

Installation points

(1) Mechanical installation

Position requirement: Install vertically inside the enclosed switchgear, leaving a minimum free space (100mm up/down, 5mm left/right; 120mm below with EMC shielding board).

Accessory installation: Before installing the optional modules (fieldbus, I/O terminals), power off and discharge are required, and touching the gold-plated contacts is prohibited; The depth of the bottom braking resistor (RB 5000) is increased by about 20mm, and the EMC shielding board can be replaced with a 24V braking module.

(2) Electrical installation

EMC measures: Separate power lines from signal lines, use shielded wires for motor cables with a large area of shielding layer, and shield brake resistor cables exceeding 30cm.

Power and protection: Use RK1 level fuses (such as Bussmann KTS-R series), and choose 300/500mA or delayed RCD circuit breakers.

DC link coupling: Only three-phase equipment can be coupled, and parameter A38 (set 1 for group 2/3) needs to be set. In case of a fault, the entire power supply needs to be disconnected, and fuses need to be replaced in pairs.

Safe torque shutdown: achieved through the ASP 5001 option, requiring dual shutdown (enable+option), with at least one functional test per month.

Connection Example

(1) Universal Connection Example

1. Connect the 24V DC brake with BRM 5000

Including power fuse, power cut-off, PE, 24V/0V power supply, BRM 5000 module (X300, X302), MDS 5000 X10 power supply, X11 24V, X1 enable, X2 terminal, X20 motor, X21 braking resistor, X4 encoder and other connection methods, marked with only/L optional equipment, DC brake motor only, brake resistor if necessary, shielding for line length>300mm and other precautions.

2. Connect 230V AC brake using interface relay

Similar to the connection with the 24V DC brake, but the 230V AC brake is controlled through an interface relay, with relevant options, motor types, brake resistor usage, and cable shielding requirements also indicated.

3. Connect the brake using Powerbox

Including power fuses, power cut-off, Powerbox module, and MDS 5000 terminal connections, labeled with options, motor types, brake resistor usage, and cable shielding requirements.

(2) Terminal connection example

Example 1

The potentiometer on AE1 (terminals X100.1, X100.3, X100.8) is powered by 18V voltage (terminal X100.19) and a voltage divider; The potentiometer on AE2 (terminals X100.4, X100.5, X100.8) provides 10V voltage through AA1 and F41 analog outputs (offset=10V, terminal X100.6); 24V power supply including option board (BA).

Example 2

Stable current analog input AE1 (terminal X100.1-3); Voltage controlled analog input AE2 (terminals X100.4, X100.5); Analog output connected to PLC (terminal X100.6-8).

Accessory selection

Core accessories: EMC shielding board (EM 5000), 24V braking module (BRM 5000), expansion I/O terminal (XEA 5001), fieldbus module (CAN5000/ECS5000).

Braking resistor: Select according to specifications (e.g. RB 5200 200 Ω for BG0, FGFT 6000W 20 Ω for BG3), UL certification requires thermal monitoring type.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands