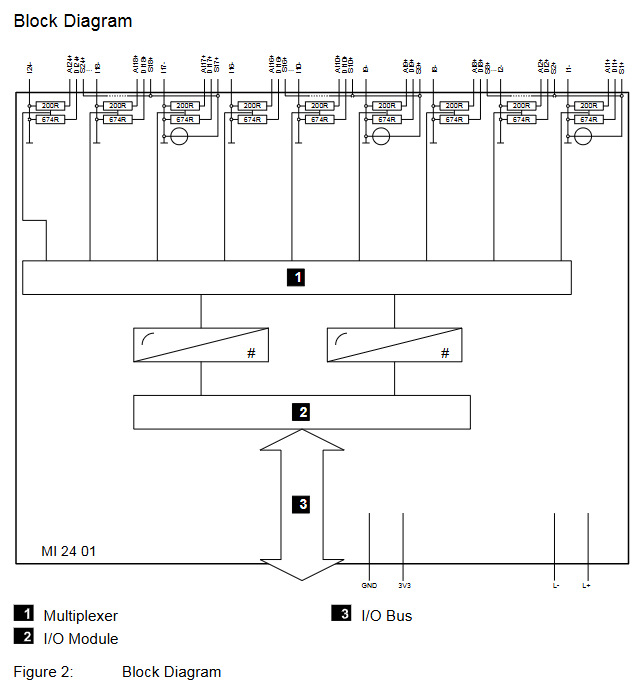

HIMA HIMatrix MI 24 01 Safety Related Controller Module (HI 800 209 E)

Rack adaptation: Only supports HIMatrix F60 modular rack, installed in slots 3-8 (slot 1 for power module, slot 2 for CPU module);

Installation steps:

Disconnect the system power and remove the cables from the front panel of the rack;

Insert the module along the upper and lower rails of the rack, press the front panel until it clicks into place with the back panel socket;

Fix the upper and lower ends of the module with screws and reconnect the cables;

Explosion proof installation (Zone 2): It needs to be installed in an enclosure with a protection level of IP54 or above, ensuring heat dissipation (maximum power consumption of the module is 16 W), and using PELV/SILV level 24 VDC power supply.

2. Wiring specifications

Cable requirements: Both analog and digital inputs must use shielded twisted pair cables, with the shielding layer grounded at one end (controller side), and a total resistance of ≤ 250 Ω (analog) and ≤ 50 Ω (digital);

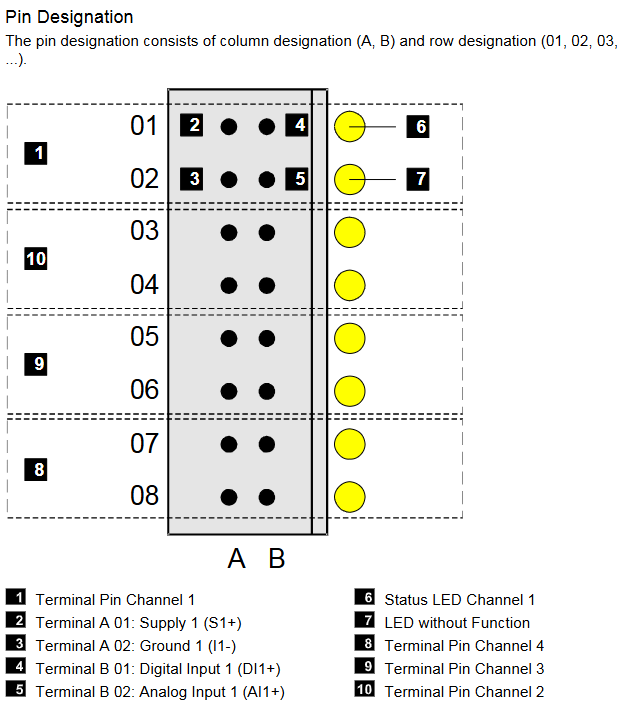

Pin allocation: 24 channels are divided into 3 groups, each group of pins including "power supply (Sx+), ground (Ix -), digital input (DIx+), analog input (AIx+)". Example (channels 1-8):

Pin Identification Function Description

A 01 S1+channels 1-8 power output

A 02 I1- Channel 1 Grounding

B 01 DI1+Channel 1 Digital Input

B 02 AI1+Channel 1 Analog Input

3. Software configuration

Tool adaptation:

System firmware<V7: configured using ELOP II Factory;

System firmware ≥ V7: Use SILworX (recommended, supports graphical interface);

Core configuration items:

Channel Type (AI/DI): Single channel independent setting Channel Used [BOOL] (1=enabled, 0=disabled);

Threshold configuration: Limit Value LOW/HIGH (DI mode: effective high and low level range; AI mode: under/over range threshold), Hysteresis LOW/HIGH (DI mode: switching threshold);

Power supply settings: Transmitter Voltage (8.2 V/26 V switching per group), Transmitter Used [BOOL] (whether to use module power supply).

Ordering and matching

1. Core components and spare parts

Component Name Model/Part Number Description

MI 24 01 module 98 2200115 24 channel safety input module (with normal coating, non optional uncoated version)

Two wire transmitter protection module 99 4703202 (H 7032) is compatible with two-wire transmitters and has SIL 3 safety protection

Three wire transmitter protection module 99 4703302 (H 7033) is compatible with three wire transmitters and has SIL 3 safety protection

The terminal plug does not have a clear part number for the module front board wiring terminal, and needs to be ordered separately

2. Documentation and technical support

Essential documents:

《HIMatrix System Manual Compact Systems》(HI 800 141 E);

《HIMatrix Safety Manual》(HI 800 023 E);

SILworX Online Help or ELOP II Factory Online Help;

Technical Support: HIMA Germany Headquarters (Phone+49 6202 709-0, Email) info@hima.com )Or regional agents (such as document provider SDS Automatyka).

Maintenance and lifecycle

Regular maintenance: Conduct precision calibration (analog input) and functional verification (safety circuit proof test) every 10 years;

Fault replacement: After a module failure, it needs to be replaced as a whole (cannot be repaired on site). When replacing, the system power supply needs to be disconnected, and the same model or HIMA certified replacement model should be used;

Scrap disposal: It is necessary to dispose of industrial electronic waste in accordance with the regulations. You can contact HIMA to sign a disposal agreement.

Key precautions

Channel configuration restrictions: 24 channels cannot be mixed into AI/DI mode and must be configured uniformly or grouped;

Power overload protection: Each group can provide a maximum of 200 mA of power. After overload, it will automatically restart within 30 seconds. If the overload persists, it will retry within 60 seconds. It is necessary to avoid connecting too many high-power devices to a single group;

Explosion proof scenario requirements: Zone 2 installation must meet EN 60079-15 enclosure protection (IP54+) and be labeled with "power-off operation only";

Software compatibility: The ELOP II Factory project and SILworX project are non editable, and compatibility needs to be confirmed before upgrading firmware.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands