Teknic SSt-6000-U Digital Servo Drive

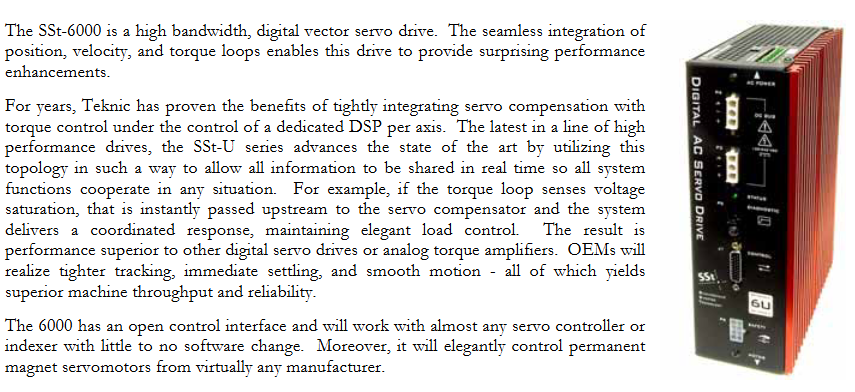

For years, Teknic has proven the benefits of tightly integrating servo compensation with torque control under the control of a dedicated DSP per axis. The latest in a line of high performance drives, the SSt-U series advances the state of the art by utilizing this topology in such a way to allow all information to be shared in real time so all system functions cooperate in any situation. For example, if the torque loop senses voltage saturation, that is instantly passed upstream to the servo compensator and the system delivers a coordinated response, maintaining elegant load control. The result is performance superior to other digital servo drives or analog torque amplifiers. OEMs will realize tighter tracking, immediate settling, and smooth motion - all of which yields superior machine throughput and reliability.

The 6000 has an open control interface and will work with almost any servo controller or indexer with little to no software change. Moreover, it will elegantly control permanent magnet servomotors from virtually any manufacturer.

Teknic SSt-6000-U Digital Servo Drive

The SSt-6000 is a high bandwidth, digital vector servo drive. The seamless integration of position, velocity, and torque loops enables this drive to provide surprising performance enhancements.

The SSt utilizes an adaptive control algorithm (IMT) based on neural fuzzy logic.

The IMT virtually eliminates the concern of inertia matching and allows for loads of large and varying inertia.

The SSt-6000-U uses small-signal, sliding-mode, automatic gain modulation to eliminate hunting even with extreme gains.

Axes will be perfectly still and have no loss of accuracy.

Some systems are high performance and others easy to use.

Few are both. The SSt’s cascading PIV control structure provides cutting edge performance with ease of use.

Even the sophisticated RAS, IMT, and Anti-Hunt are easy to set up

Key technical specifications

Basic and environmental parameters

Physical dimensions and weight - Dimensions: 8.93 x 5.56 x 3.15 inches (227 x 141 x 80 mm)

-Weight: 71.8 ounces (2035 g)

Working environment - Temperature: 0~40 ℃ (no condensation)

-Humidity: 0~95% RH (non condensing)

-Installation: Vertical installation on metal surface (with reserved heat dissipation space)

Compliance - Electrical Safety: EN 61010, UL 508C

-Electromagnetic compatibility (EMC): EN 50081-2 (emission), EN 50082-2 (anti-interference)

-Mechanical safety: EN 954-1 (requires compliant power control)

Power output and motor compatibility

Output current - peak current: 23 A (continuous for 3 seconds)

-Rated current: 9 A RMS (vertically installed on metal surface), 12 A RMS (with fan cooling)

PWM characteristics: 28 kHz center balanced vector PWM ripple frequency, reducing motor operating noise and heat generation

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands