Emerson MMS 3120 Dual Channel Bearing Vibration Transmitter

Emerson MMS 3120 Dual Channel Bearing Vibration Transmitter

Equipment Overview

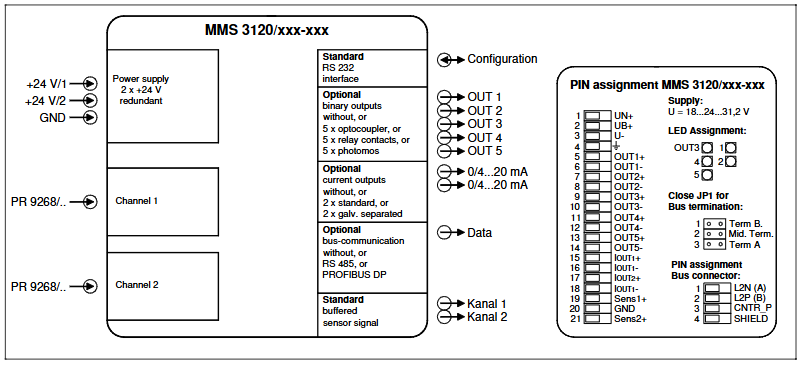

The MMS 3120/xxx-xxx dual channel bearing vibration transmitter is part of the improved MMS 3000 transmitter system, used for monitoring and protecting various types of turbomachinery. This transmitter has highly flexible hardware options and multiple combination possibilities, which can best adapt to the needs of the corresponding factory. It achieves economic measurement and monitoring of absolute bearing vibration through the use of seismic absolute vibration sensors, and complies with VDI 2056/.. And API 670 standards.

Application scenarios

Suitable for various types of turbomachinery, fans, compressors, gearboxes, pumps, and similar rotating machinery. Due to its bus capability, it is suitable for both large systems equipped with programmable logic controllers and hosts (such as power plants, refineries, and chemical plants) and small factories with few measurement points and scattered data processing. Can be used in conjunction with all EPR absolute bearing vibration sensors, such as PR 9268/20, PR 9268/30, PR 9268/60, and PR 9268/70.

Function and Design

Signal conversion: Convert the signal of a vibration sensor into two independent signals proportional to the vibration velocity or amplitude (peak to peak), or output signals proportional to the maximum value of these characteristic values.

Monitoring function: Integrated module and sensor monitoring function, capable of detecting faults in sensors and module electronic devices. In the event of an error, the status of the "OK" output will change, and the 4-20 mA current output will indicate 0 mA.

Configuration method: All necessary configurations are completed through MMS 3910W configuration software. The transmitter comes with standard configurations suitable for most applications at the factory, or other configurations can be made at the factory according to requirements.

Technical parameters

Sensor Input

Two independent inputs for PR 9268/20, PR 9268/30, PR 9268/60, and PR 9268/70 seismic vibration sensors.

Sensor connection: Harting connector.

Measurement range: It can be freely selected through configuration software based on the measurement range of the applied sensor.

Frequency range (-3dB): High pass filter 5/10/15 Hz; low-pass filter 50... 1500 Hz.

output

Current output: The standard is two current outputs, proportional to the selected characteristics and related to system grounding, which can be freely allocated to the measurement channel; Choose between two electrically isolated current outputs or no current output. The output range is 0/4... 20 mA or 20... 4/0 mA, with a maximum load of 500 ohms and open and short circuit protection.

Buffer sensor signal: Two signal outputs for analysis and diagnosis, one for each channel, proportional to the dynamic sensor signal, accessed through terminals, unfiltered voltage output of ± 5.0 V, with an error of ± 2.5%.

Function output: A total of 5 function outputs are provided, which can be freely allocated through configuration software to indicate limit values or clear channel status, etc. There are multiple options, such as no function output, 5 optocoupler outputs, 5 relay contacts (normally open contacts), 5 photoelectric MOS relays, etc.

Data interface: The standard is RS 232 interface, used for transmitter configuration and measurement data display; Optional RS485 bus (with epro protocol V2.0) and PROFIBUS DP.

Accuracy and stability

Linear error (without sensor): 0.2% at 25 ° C.

Linear error (with sensor):<2.2% at 25 ° C.

Output temperature stability:<0.08%/10K.

Long term drift: up to 1% of full scale.

Power supply: Optional redundant power supply, with diode decoupled LED, nominal voltage+24 V DC, voltage range+18...+31.2 V DC, power consumption depends on built-in options, maximum 6 W.

Shell and Protection

Shell: Aluminum, non corrosive.

Protection level: IP 65 (compliant with DIN 40050, IEC 144), CE certification, EMC testing in accordance with EN 55011 and EN 61326.

Environmental conditions (compliant with IEC 359, DIN 43745)

The maximum allowable temperature for installation surface is 65 ° C (90 ° C when installed on bolts with a spacing of 10mm).

Working temperature range: -20...+65 ° C (-20...+45 ° C when installed on 10 mm spaced bolts).

Allowable relative humidity: 0... 95%, no condensation.

Vibration and impact: impact 20 g/2 ms; Vibration at 5 g/60 Hz.

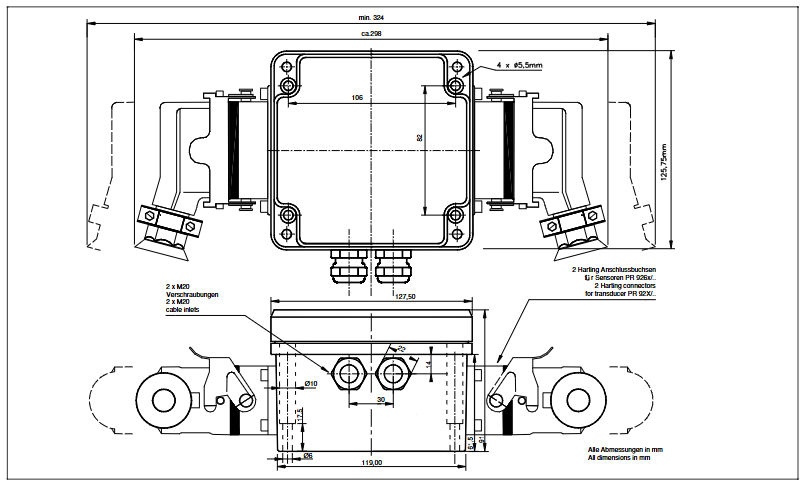

Installation and Dimensions: The preferred installation direction is downwards with the cable gland. Please refer to the drawing for the dimensions. The maximum net weight is 1.3 kg and the maximum gross weight is 1.5 kg.

Module and sensor monitoring

Internal module monitoring continuously checks the following functions: whether the input signal is within the predefined range; Is the cable between the transmitter and sensor normal (no short circuit/broken wire); System voltage. The monitoring status of modules and sensors can be signaled through the switch contacts of functional outputs.

Configure parameters and operating modes

Main configuration parameters: configured through MMS 3910W configuration software, adjustable parameters include KKS identification for each channel, operating mode, sensor sensitivity, series resistance of safety barriers, measurement range, etc. (may vary depending on the selected operating mode and measurement function).

Operation mode: Provides multiple measurement modes, which can be configured through MMS 3910W configuration software. In single channel and dual channel modes, the selectable measurement modes include vibration amplitude (SO-P, SP-P, MAX (x, y)) and vibration velocity (VRMS, MAX (x, y)).

Ordering options and standard models

Ordering Options

Communication: RS 232, RS 485, PROFIBUS DP.

Sensor inputs K1 and K2: two identical input channels that cannot be mixed, corresponding to PR 9268/.

Output characteristics: None; 2 with system reference (standard); Two electrical isolations.

Function output: None; 5 optocouplers (standard); 5 relay contacts (normally open contacts); 5 photoelectric MOS.

Display: None (standard); Equipped with an 8-bit display.

Standard Model

MMS 3120/010-000: Sensor PR 9268/.., RS 232, no bus communication, current output with common ground, no functional output, no display, order number 9100-03025.

MMS 3120/011-000: Sensor PR 9268/.., RS 232, no bus communication, current output with common ground, functional output, no display, order number 9100-03026.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands