MOOG G128-809A DIN rail power supply

4. Compliance and Security Certification

The CE mark indicates that it complies with the EU Low Voltage Directive and Electromagnetic Compatibility Directive, and has passed relevant emission and immunity tests to ensure the legal sale and safe use of the product in industrial environments.

Typical industrial application scenarios

G128-809A power supply is widely used in applications that require 24VDC standard industrial voltage:

Industrial automation control system: provides main power for PLC (Programmable Logic Controller), remote I/O modules, sensors, relays, pneumatic valve islands, etc.

Process control and instrumentation: Provide power to field instruments such as flow meters, analyzers, and recorders.

Mechanical equipment and production lines: used for control circuits, human-machine interfaces (HMI), and small drive devices in CNC machine tools, packaging machinery, and assembly lines.

Building automation: powering controllers for lighting control and security systems (such as access control and cameras).

Communication and Network Infrastructure: Provides DC power to industrial switches, routers, fiber converters, and other network equipment.

Installation, wiring, and usage precautions

Installation: Ensure installation in a well ventilated location away from heat sources. Firmly mounted on a standard 35mm DIN rail.

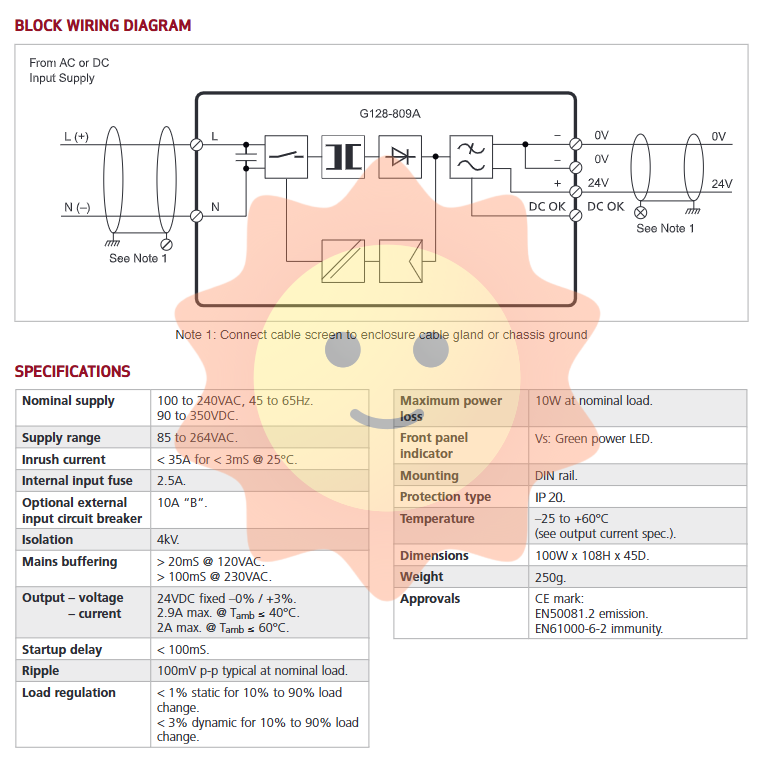

Input wiring: Connect the L/N (AC) or+/- (DC) input lines correctly according to local electrical specifications. Be sure to ensure that the input voltage is within the specified range.

Output wiring: Use cables of appropriate diameter to connect the output terminals (+24V and 0V). Pay attention to the positive and negative poles and avoid reverse connection.

Grounding and shielding: It is necessary to connect the shielding layer of the input cable (if any) to the cable gland or chassis grounding point of the enclosure to ensure good EMC performance and safety.

Heat dissipation considerations: Ensure sufficient air flow around during high temperature environments or full load operation. When multiple power supplies are installed in parallel, appropriate spacing should be left.

Maintenance: The power module does not require regular maintenance. If the internal fuse is blown, it needs to be replaced by a professional after checking the cause of the fault.

Selection Guide and Key Points for Competitive Comparison

When selecting G128-809A or similar products, engineers should focus on evaluating the following parameters:

Does the input voltage range cover the fluctuation range of the on-site power grid.

Whether the output current meets the total load demand of the system and considers the environmental temperature derating.

Efficiency and losses affect system temperature rise and operating costs.

Is the protection function (short circuit, overload, overvoltage) complete.

Whether the installation method and size match the layout of the control cabinet.

Whether the certification and standards comply with the regulatory requirements of the target market.

Brand reliability, MTBF data, and after-sales service.

Moog G128-809A has formed comprehensive advantages in wide input range, high isolation voltage, high MTBF, and compact DIN design, making it particularly suitable for industrial applications that require high reliability, safety, and space utilization.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands