MOOG QAIO 16/4 Analog I/O Module Technology Analysis and Application Guide

MOOG QAIO 16/4 Analog I/O Module Technology Analysis and Application Guide

In industrial automation and control systems, accurate acquisition and reliable output of analog signals are the foundation for achieving process monitoring and closed-loop control. The QAIO 16/4 analog I/O expansion module, jointly launched by Moog and Berghof Automation, serves as the M3000 ® The control system and CANtrol automation system are important components that provide engineers with high-density and high-precision analog signal processing capabilities. This article will provide a comprehensive and in-depth analysis of this classic module from multiple perspectives, including module overview, technical details, safety specifications, installation and wiring, signal processing, and system integration.

Product Overview and System Positioning

The QAIO 16/4 module is an extension module designed specifically for expanding the analog I/O capabilities of cell controllers. It is connected to the system through direct E-Bus coupling, providing two input type variants: QAIO 16/4-V (voltage input) and QAIO 16/4-A (current input). The core function of the module is to serve as a high-precision bridge between the on-site analog sensor and the upper control unit.

Its design strictly follows the international standard IEC 61131 (Programmable Logic Controller) series and meets the EMC (Electromagnetic Compatibility) requirements in industrial environments (EN 50081-2/EN 50082-2). The module emphasizes reliable operation in industrial noise environments and provides detailed safety operation guidelines and shielding wiring specifications for this purpose.

Core functions and electrical characteristics

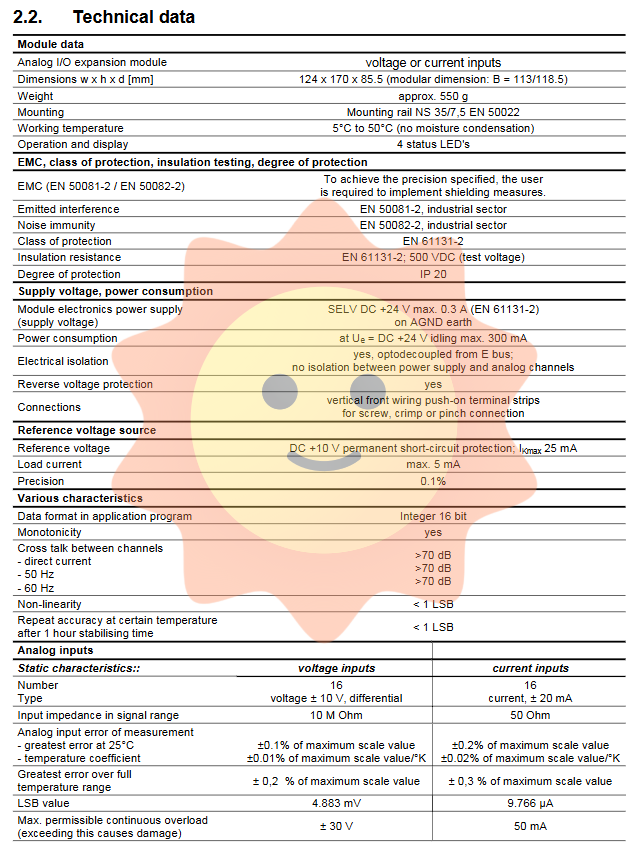

1. Analog input channel

Number of channels: 16.

Input type:

V version: Differential voltage input, with a range of ± 10V.

Version A: Current input, with a range of 0... 20mA (actual support ± 20mA).

Resolution: 11 bits+sign bit, equivalent to a 16 bit integer representation (-32768 to+32752).

Accuracy (25 ° C):

Voltage input: ± 0.1% full scale.

Current input: ± 0.2% full range.

Temperature coefficient: extremely low, at ± 0.01%/K (voltage) and ± 0.02%/K (current) respectively, ensuring stability over a wide temperature range (0-50 ° C operating temperature).

Input impedance: voltage input up to 10M Ω, current input is 50 Ω.

Overload protection: Equipped with protective diodes, it can withstand continuous overload up to ± 30V (voltage) or 50mA (current) without damage.

Common mode rejection ratio: ≥ 70 dB, effectively suppressing common mode interference.

2. Analog output channel

Number of channels: 4.

Output type: Floating voltage output, with a range of ± 10V.

Resolution: 11 bits+sign bit.

Accuracy (25 ° C): ± 0.15% of full scale.

Output capability: Maximum output current of 5mA, with permanent short-circuit protection (short-circuit current limit of 25mA).

Dynamic performance: setup time<1ms, slew rate>8 V/μ s.

Load requirements: minimum load resistance of 2k Ω, maximum capacitive load<1000 pF.

3. Module reference voltage source

Output:+10 VDC.

Accuracy: ± 0.1%.

Load capacity: Maximum load current of 5mA, also equipped with permanent short-circuit protection (current limit of 25mA). This power supply can provide stable excitation for external sensors such as potentiometers and bridges.

4. General module characteristics

Power supply: 24 VDC SELV (safe extra low voltage), maximum current consumption of 0.3A, with reverse polarity protection.

Isolation: The electronic part of the module is isolated from the E-Bus through optocouplers; But there is no electrical isolation between the module power supply (24V) and the analog channel, and they share AGND (analog ground). This is a key point in design and application.

Physical characteristics: Dimensions 124 x 170 x 85.5 mm, weight approximately 550g, installed on NS 35/7.5 DIN rails.

Protection level: IP20, suitable for installation inside cabinets.

Status indication: 4 LED indicator lights, respectively indicating L+(24V power supply), ± 15V (analog unit power supply),+5V OUT (E-Bus communication), and OUT-INA (output enabled) status.

Safe operation and qualified user requirements

The manual emphasizes safety at the beginning and defines four levels of warning signs:

danger Failure to comply will result in death, serious injury, or significant property damage.

Warning! Failure to comply may result in death, serious injury, or significant property damage.

Caution: Failure to comply may result in minor injuries or property damage.

Annotation: Provide important product information or document guidance.

The module only allows qualified users to operate, that is, professionals who have been trained, authorized, and able to debug, ground, and mark equipment according to safety engineering standards. The system is designed for environments with overvoltage category I, with a rated supply voltage not exceeding 1000 VAC or 1500 VDC.

The manual specifically warns that any malfunction of specific components in an electronic control system may result in uncontrollable operation. When designing safety related systems, all failure modes must be considered and manufacturers may need to be consulted.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands