MOOG G128-809A DIN rail power supply

MOOG G128-809A DIN rail power supply

In the fields of industrial automation, process control, and mechanical manufacturing, a stable and reliable power supply is the foundation for ensuring the continuous operation of the system. The G128-809A DIN rail power supply launched by Moog has become an ideal power supply choice for many industrial applications due to its wide range of inputs, high efficiency conversion, high reliability design, and compact structure. This article will provide a comprehensive and in-depth analysis of the power module from multiple dimensions, including technical specifications, design features, application scenarios, and selection guidance.

Product Overview and Core Positioning

G128-809A is a compact DIN rail mounted power supply that uses switch voltage regulation technology. Its main function is to convert AC or DC input into a stable 24VDC output, suitable for various industrial equipment that requires DC power supply. This power supply can provide up to 2.9A of continuous output current when the ambient temperature does not exceed 40 ° C, meeting the needs of most small and medium power loads.

Its design follows strict requirements in industrial environments, with safety features such as air defense idle operation, short circuit protection, and high isolation voltage. It has also passed CE certification and complies with EN50081-2 (emission) and EN61000-6-2 (immunity) standards, ensuring stable operation in complex electromagnetic environments in industrial sites.

Detailed technical specifications and performance analysis

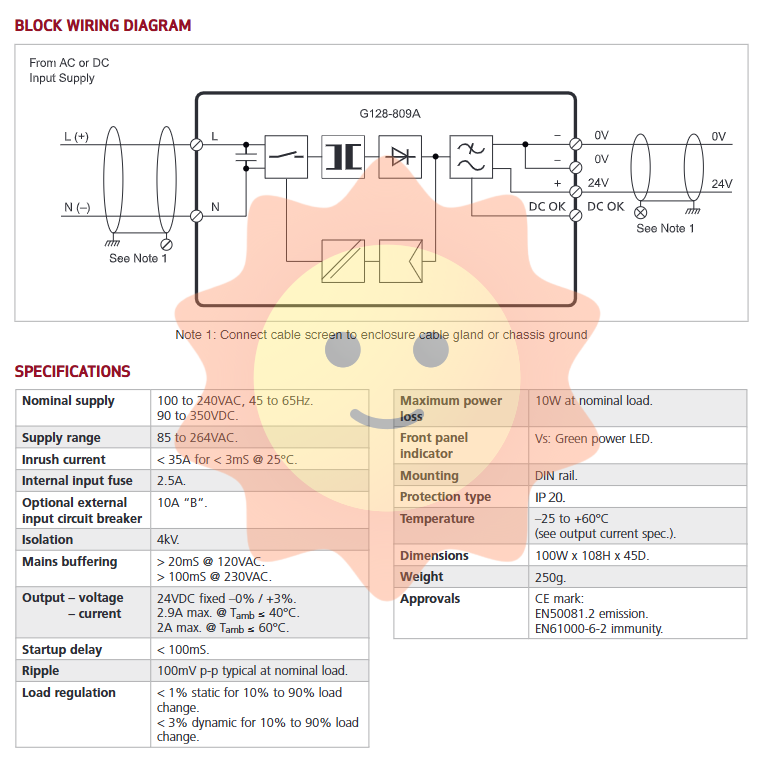

1. Input characteristics

Wide range input: Supports 85-264VAC (45-65Hz) AC input or 90-350VDC DC input, enabling it to adapt to most global power grid standards and some DC bus systems.

Buffer capacity: Under 120VAC input, the buffer time of the main power supply is greater than 20ms; under 230VAC input, it is greater than 100ms, effectively responding to short-term power grid interruptions.

Surge current limitation: When starting, the surge current is below 35A (duration<3ms, @ 25 ° C), reducing sensitivity to power on shocks.

Built in protection: equipped with a 2.5A internal input fuse, and it is recommended to choose a 10A "B" type external input circuit breaker to build a dual protection mechanism.

High isolation: There is 4kV electrical isolation between input and output, which enhances system safety and anti-interference ability.

2. Output characteristics

Voltage stabilization accuracy: The output voltage is fixed at 24VDC, with an accuracy range of -0%/+3%, providing a highly stable DC power supply.

Load capacity: Output current capacity varies with environmental temperature:

When ≤ 40 ° C: maximum 2.9A (continuous).

When ≤ 60 ° C: maximum 2A (continuous). When designing, it is necessary to reduce the rating according to the actual working temperature.

Low ripple noise: The typical ripple voltage is 100mV peak to peak (under rated load), providing clean power for sensitive control circuits.

Load adjustment rate:

Static adjustment rate:<1% (load varies between 10% and 90%).

Dynamic adjustment rate:<3% (load varies between 10% -90%), fast response, stable output.

3. Efficiency and reliability

High efficiency: The conversion efficiency exceeds 80%, which helps reduce equipment heating and energy consumption.

High reliability: The mean time between failures (MTBF) is as high as 500000 hours, reflecting its design goals of long lifespan and high reliability.

Low power consumption: The maximum power loss under rated load is only 10W.

4. Mechanical and environmental characteristics

Installation method: Standard DIN rail installation (compliant with EN60715 standard), convenient for quick deployment and maintenance inside the control cabinet.

Protection level: IP20, suitable for the protection requirements of cabinet installation.

Working temperature: -25 ° C to+60 ° C, with a wide temperature range suitable for most industrial environments.

Size and weight: Compact size of 100mm (width) x 108mm (height) x 45mm (depth), weighing only 250g, saving installation space.

Status indication: The front panel is equipped with a green LED power indicator light (Vs) for easy status monitoring.

Core design features and advantages

1. Advantages of Switching Power Supply Technology

Adopting a high-frequency switching voltage regulation design, it has significant advantages in efficiency, volume, and weight compared to traditional linear power supplies. Efficiency>80% reduces energy waste and heat dissipation pressure, and the compact DIN housing design maximizes the use of control cabinet space.

2. Powerful protection function

Short circuit protection: When the output terminal is short circuited, the power supply automatically enters a protection state to prevent damage.

Anti idle (anti no-load oscillation): Ensure stable operation under no-load or extremely light load to avoid abnormal output voltage.

Input surge suppression and buffering: effectively responding to power grid fluctuations and short-term power outages, enhancing system resilience.

3. Redundancy and scalability

Supporting parallel connections, it can be used to build redundant power supply systems and improve power supply reliability in critical application scenarios. When parallel connection, attention should be paid to current sharing design to ensure that each module evenly shares the load.

4. Compliance and Security Certification

The CE mark indicates that it complies with the EU Low Voltage Directive and Electromagnetic Compatibility Directive, and has passed relevant emission and immunity tests to ensure the legal sale and safe use of the product in industrial environments.

Typical industrial application scenarios

G128-809A power supply is widely used in applications that require 24VDC standard industrial voltage:

Industrial automation control system: provides main power for PLC (Programmable Logic Controller), remote I/O modules, sensors, relays, pneumatic valve islands, etc.

Process control and instrumentation: Provide power to field instruments such as flow meters, analyzers, and recorders.

Mechanical equipment and production lines: used for control circuits, human-machine interfaces (HMI), and small drive devices in CNC machine tools, packaging machinery, and assembly lines.

Building automation: powering controllers for lighting control and security systems (such as access control and cameras).

Communication and Network Infrastructure: Provides DC power to industrial switches, routers, fiber converters, and other network equipment.

Installation, wiring, and usage precautions

Installation: Ensure installation in a well ventilated location away from heat sources. Firmly mounted on a standard 35mm DIN rail.

Input wiring: Connect the L/N (AC) or+/- (DC) input lines correctly according to local electrical specifications. Be sure to ensure that the input voltage is within the specified range.

Output wiring: Use cables of appropriate diameter to connect the output terminals (+24V and 0V). Pay attention to the positive and negative poles and avoid reverse connection.

Grounding and shielding: It is necessary to connect the shielding layer of the input cable (if any) to the cable gland or chassis grounding point of the enclosure to ensure good EMC performance and safety.

Heat dissipation considerations: Ensure sufficient air flow around during high temperature environments or full load operation. When multiple power supplies are installed in parallel, appropriate spacing should be left.

Maintenance: The power module does not require regular maintenance. If the internal fuse is blown, it needs to be replaced by a professional after checking the cause of the fault.

Selection Guide and Key Points for Competitive Comparison

When selecting G128-809A or similar products, engineers should focus on evaluating the following parameters:

Does the input voltage range cover the fluctuation range of the on-site power grid.

Whether the output current meets the total load demand of the system and considers the environmental temperature derating.

Efficiency and losses affect system temperature rise and operating costs.

Is the protection function (short circuit, overload, overvoltage) complete.

Whether the installation method and size match the layout of the control cabinet.

Whether the certification and standards comply with the regulatory requirements of the target market.

Brand reliability, MTBF data, and after-sales service.

Moog G128-809A has formed comprehensive advantages in wide input range, high isolation voltage, high MTBF, and compact DIN design, making it particularly suitable for industrial applications that require high reliability, safety, and space utilization.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands