MOOG Servo Electronics Products

MOOG servo electronic system: modular cornerstone for building precision electro-hydraulic servo control

In high-precision and high dynamic response application fields such as industrial automation, aerospace, testing, and heavy machinery, electro-hydraulic servo systems have become the core solution for achieving precision motion and force control due to their advantages of high power density, fast response, and high stiffness. However, a high-performance servo system not only requires high-quality valves and actuators, but also the quality of its "brain" and "nerve" - servo electronic control system - often directly determines the performance boundary and reliability of the entire system. Moog, as a global leader in electro-hydraulic servo technology, not only provides top-notch servo valves and actuators, but also builds a comprehensive, modular, and highly flexible servo electronic product ecosystem. This article aims to deeply analyze Moog's three major electronic platforms, Eurocard, Snap Trac, and DIN Rail, and reveal how they provide engineers with the flexibility and powerful functionality of "LEGO bricks" to tackle various challenges ranging from simple open-loop to complex multi axis closed-loop control.

Three major platforms: strategic division for different integration requirements

Moog's servo electronic products are not a single model stack, but are strategically divided into three platforms based on system complexity, channel quantity, installation environment, and cost considerations, reflecting a clear product philosophy.

Eurocard: a professional choice for multi-channel and complex systems

The Eurocard platform adopts a standard 19 inch rack mounted card structure, which is an ideal choice for dealing with multi-channel servo systems or complex control systems. A standard rack can accommodate one power card and up to nine functional cards. The advantages of this centralized architecture are:

High density integration: many functions such as servo amplifier, signal conditioner, oscillator/demodulator, PID controller, ramp generator, etc. are centralized in one chassis, with neat wiring and high space utilization.

Excellent anti-interference and heat dissipation: Installed in professional electrical cabinets, the environment is controllable, especially suitable for complex electromagnetic environments or situations with extremely high reliability requirements.

Powerful expansion capability: Standardized card slots and backplane bus for easy addition and upgrade of future features. The document clearly states that when the system requires more than three servo loops, it is recommended to use Eurocard electronic devices.

Snap Trac: A Flexible and Economical Modular Industrial Solution

The Snap Trac platform is a reliable, low-cost option tailored for industrial equipment design. Its core lies in "modularity" and "ease of use": the circuit board adopts a modular design, which can be directly inserted into standard PVC tracks, achieving "plug and play" convenient installation, maintenance, and replacement.

Installation flexibility: The card can be fixed at any position along the track, making it particularly suitable for use in control cabinets with limited space or frequent configuration adjustments.

Easy maintenance: High quality plug-in screw terminal connectors are used, and a large number of front panel test points and 20 turn precision potentiometers are set up, greatly facilitating on-site debugging and troubleshooting.

Applicable scenarios: It is usually recommended for single channel or dual channel systems and is the preferred choice for OEM equipment manufacturers and system integrators to achieve economical servo control.

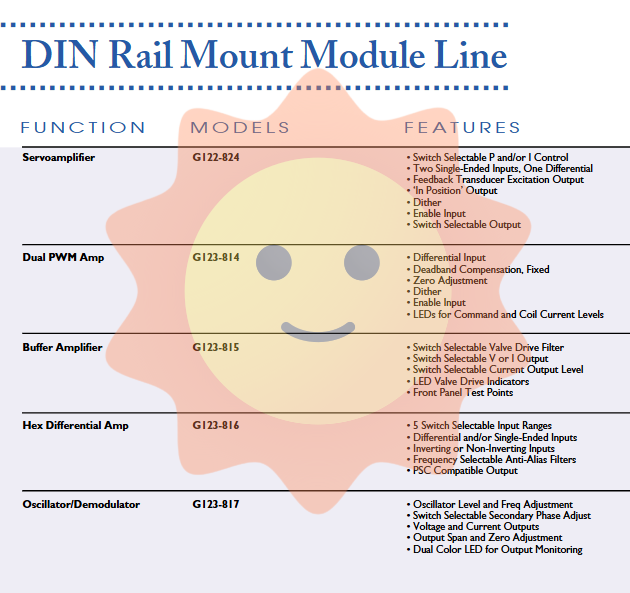

DIN Rail: The Answer to Compact Space and Standardized Installation

The DIN Rail rail installation module is designed specifically for cabinets with limited installation space. All modules comply with the CE mark and are uniformly powered by 24 VDC. They can be installed on standard 35mm DIN rails, making installation and removal extremely easy. This series of products embodies the highest degree of standardization and compactness, making them ideal as dedicated servo interface modules in large PLC control systems or for implementing specific servo functions in small spaces.

Core functional module: The "functional organ" of the servo system

No matter which platform is used, the construction of the system relies on a series of modules with clear functions. These modules are like functional organs in precision instruments, each performing their own duties and working together.

Servo amplifier: the "power core" of the system. For example, the G122-202A1 enhanced servo amplifier not only provides PID control and 10-100mA output, but also integrates rich functions such as slope generator, 4-20mA to 0-10VDC converter, and Dither selection, making it almost a single card universal servo controller.

Servo controller, such as N122-001, is designed for complex control and typically includes an inner and outer loop control (such as the inner loop used to control a three-stage servo valve with LVDT spool feedback). Multiple configurations can be selected through jumper wires, and it has independent gain adjustment and current limiting functions.

Exciter/Demodulator: The core interface required for sensors such as Linear Variable Differential Transformer (LVDT) or RVDT (Rotary Transformer). NF123-204A1 provides adjustable excitation frequency (100-2500Hz) and amplitude (2-11Vp-p), and demodulates the AC modulation signal of LVDT into a DC voltage signal proportional to the displacement of the iron core, which is the key to forming a high-precision position closed loop.

Signal Conditioner: Used to process weak millivolt level differential signals generated from strain gauges, pressure sensors, load units, etc. Like NF123-211A1, gain range adjustment for jumper selection, signal summation amplification, and stable DC power supply can be provided to the sensor.

Ramp Generator: Convert step input commands into ramp outputs with adjustable slopes, used to control the acceleration and deceleration of the system, achieve smooth start stop, and avoid impact. This function is often integrated into the main servo amplifier card.

I/V converter, F/V converter: realize interface conversion of different signal formats. For example, converting the 4-20mA current command output by the PLC into a ± 10V voltage command (I/V), or converting the frequency signal of the pulse encoder into a DC voltage (F/V) proportional to the speed.

DC level detector/comparator: used as a window comparator, it triggers a relay or logic output when the input voltage reaches a preset level. Commonly used for speed arrival indication, zero point detection, or "Bang Bang" control.

Power module: Provides stable and pure ± 15Vdc, ± 24Vdc, and+5Vdc (for logic circuits) power to the entire electronic system. High end models have functions such as low ripple, low noise, overload protection, and power failure alarm output.

From Theory to Practice: Construction and Debugging of Typical Closed loop Control Systems

The document spends a lot of space, vividly demonstrating how to use Moog electronic modules to build a classic control system through detailed system diagrams, wiring diagrams, and step-by-step setup processes. This is not only a product description, but also a valuable engineering application guide.

Closed loop position control: This is the most fundamental and common application. The system consists of servo amplifiers, servo valves, hydraulic cylinders, and position sensors (such as DCDT or magnetostrictive displacement sensors). The core principle is that the servo amplifier compares the command input with the sensor feedback, generates an error signal to drive the servo valve, and moves the hydraulic cylinder until the feedback is consistent with the command and the error is zero. The document provides detailed construction and debugging steps from open-loop manual control to closed-loop PID control, emphasizing the sequence and importance of bias and gain adjustment.

Closed loop control of three-stage servo valve: For high flow applications, a three-stage servo valve is required. The Moog scheme cleverly utilizes exciter/demodulator cards to close the inner loop of the valve core position. LVDT detects the actual position of the three-stage valve core, and the demodulated DC voltage is sent to the servo amplifier together with the feedback signal from the external position sensor to form the outer loop. This independently adjustable structure of the inner and outer rings can ensure high-precision and fast positioning of the valve core, as well as precise control of the final load.

Closed loop force control: The system consists of servo valves, actuators, pressure sensors or load units, and servo amplifiers. The key lies in the application of signal conditioners, which amplify and condition the weak differential signal of strain gauge pressure sensors into a standard force feedback signal (force=area x pressure). The servo amplifier compares the force command with the force feedback, controls the opening of the valve to adjust the pressure in both chambers of the actuator until the output force matches the command. The document provides detailed instructions on how to use a regulator for zero (ZERO) and span (SPAN) calibration to achieve accurate force conversion in non equal area cylinders.

Closed loop speed control (with acceleration limitation): Typically, servo motors are used, and speed feedback is provided by a DC tachometer (Tachometer). The system forms a speed loop through a servo amplifier (often set as integral I control to achieve zero static error tracking). The ramp generator (or built-in amplifier function) is used to limit acceleration. The document specifically introduces how to interface with a PLC that outputs 4-20mA analog signals, requiring the use of an I/V conversion card.

Example of a complex multi axis PLC servo system: The document presents a highly representative dual axis (X-Y) PLC control system. Among them, the Y-axis (linear) uses I/V conversion card, ramp generator card, servo amplifier card, and position feedback conditioning card to achieve position closed-loop with acceleration and deceleration control. The X-axis (rotation) uses I/V conversion card, servo amplifier card, and introduces F/V conversion card to convert incremental encoder pulses into speed feedback, and then provides the "speed arrival" signal to the PLC through the DC level detector card. This example perfectly illustrates how to combine Moog's modular electronic products with an economical PLC with only discrete I/O points to build a fully functional complex motion control system.

Core advantages and engineering design philosophy

Through in-depth analysis of the product system, we can summarize the core advantages and design philosophy of Moog servo electronic products:

Ultimate modularity and flexibility: Users can choose and combine function cards based on specific needs (position, speed, force, single axis, multi axis, simple, complex) like building blocks, without the need to design circuits from scratch for each new project, significantly shortening development cycles and reducing costs.

Engineering oriented usability design: ubiquitous front panel testing points, multi turn precision potentiometers, clear LED status indicators, plug-in connectors, and detailed setup process documents, all aimed at reducing the difficulty of debugging and maintenance for on-site engineers.

Forward compatibility and reliability: New product series (such as NF series) are often designed as "forward compatible alternatives" to old series (such as F series), protecting users' long-term investments. The product has undergone rigorous testing and has a wide operating temperature range (-20 ° C to 50 ° C), making it suitable for industrial environments.

Complete ecological support: From core electronic modules to various sensors (LVDT, DCDT, magnetostrictive rods, pressure sensors, rotary transformers), to valve testers (used for rapid on-site diagnosis of servo valve status) and rich installation accessories, Moog provides a one-stop solution.

Professional application support and warning: The document emphasizes the complexity of closed-loop system design at the end and provides a "serious warning". Moog explicitly pointed out that due to numerous variables such as load type, pipeline length, component selection, loop gain, friction, clearance, etc., even if each individual piece performs perfectly, problems such as oscillation, overshoot, and even danger may occur after forming a closed loop. This reflects Moog's professional sense of responsibility as an industry leader. It is recommended that users exercise extreme caution during initial power on and debugging, and encourage them to utilize Moog's experienced engineering department for system analysis and auxiliary design.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands