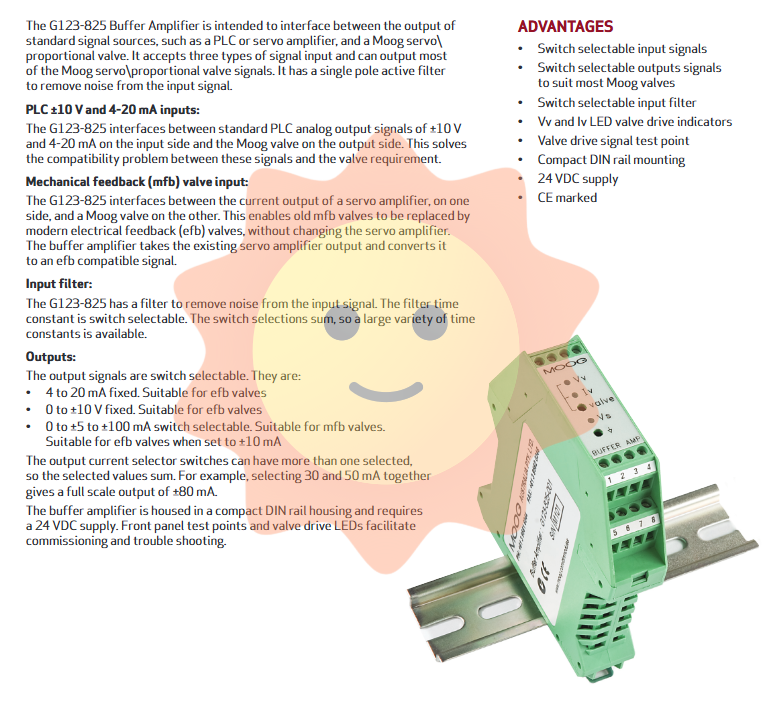

MOOG G123-825-001 DIN rail buffer amplifier

MOOG G123-825 Buffer Amplifier: A General Signal Interface and Modern Transformation Bridge for Industrial Servo Control Systems

In modern industrial automation, mechanical manufacturing, and process control systems, electro-hydraulic servo and proportional technology continue to play a key role due to their high power density, fast response, and precise control capabilities. However, when building or maintaining a high-performance servo system, engineers often face a fundamental but tricky challenge: compatibility of signal interfaces. Controllers from different eras (such as PLCs, motion control cards), servo amplifiers, and actuators (servo valves/proportional valves) may use vastly different signal formats (voltage, current, range), which are like barriers between different languages, hindering the lossless transmission of information and maximizing system efficiency. The G123-825-001 buffer amplifier launched by Moog is a sophisticated solution designed to eliminate this obstacle. It is not just a signal amplifier, but also a highly integrated, flexible and configurable "universal translator" and "signal guardian", providing unprecedented convenience and reliability for system integration, equipment upgrades, and daily maintenance.

Core positioning: Cracking three typical interface compatibility problems

The design philosophy of G123-825 buffer amplifier directly points to the three most common types of signal interface pain points in industrial sites, and its core value lies in its "bridge" role.

Interface Bridge between PLC Standard Analog Output and Servo Valve

Modern PLCs widely use ± 10V or 4-20mA as standard analog output signals. However, the numerous models of electrical feedback (EFB) servo valves/proportional valves from Moog may require specific current or voltage drive ranges. Direct connection may result in the valve not being able to operate at full stroke, abnormal sensitivity, or even damage. G123-825 perfectly solves this contradiction. It receives ± 10V or 4-20mA signals from the PLC side and can be flexibly configured as the precise driving signal required by the valve on the output side through a dip switch (such as a fixed 4-20mA or 0 to ± 10V), ensuring lossless and accurate transmission of command signals from the controller to the actuator end.

Modernized bridge renovation with replacement of old and new valves

In equipment lifecycle management, there is often a need to replace old mechanical feedback (MFB) valves with modern electrical feedback (EFB) valves that have better performance and higher reliability. However, the original servo amplifiers were usually designed and tuned for the current drive characteristics of MFB valves, such as a specific value within the range of 0 to ± 100mA. If the valve is replaced along with the amplifier, the cost is high and may involve complex system re debugging. G123-825 demonstrates its enormous value in this scenario: it receives the drive current output from the original servo amplifier and "converts" it into a compatible signal required by the EFB valve (e.g. set to ± 10mA output to match a typical EFB pilot stage). This means that users can seamlessly upgrade valves without changing the original core control electronic equipment (servo amplifier), greatly reducing the difficulty, cost, and risk of renovation and protecting existing investments.

The Guardian of Purifying Signal Noise

Electromagnetic interference in industrial environments is complex, and analog signals transmitted over long distances are prone to introduce noise. These noises, amplified by servo amplifiers, may cause small but harmful "vibrations" in valves, affecting system stability, accuracy, and actuator life. G123-825 is equipped with a single pole active filter, and its transition frequency can be flexibly selected through a dip switch (providing multiple levels such as 7, 16, 34, 72, 723 Hz, and can be combined and stacked). Engineers can finely adjust the filtering strength based on the actual noise spectrum and response speed requirements of the system, effectively filtering out high-frequency interference, ensuring that the command signal input to the valve is pure and smooth, thereby improving the stability and dynamic quality of the entire closed-loop system.

Flexible configuration: "Universal output" achieved by dip switch

The flexibility of G123-825 is fully demonstrated in its output configuration, which enables it to adapt to the vast majority of Mug servo valves and proportional valves.

Output mode selection: The output can be set to:

Fixed 4-20mA: Suitable for EFB valves with a large number of standard current inputs.

Fixed from 0 to ± 10V: suitable for EFB valves that require voltage drive.

Adjustable from 0 to ± 5mA to ± 100mA: This mode is designed to match various MFB valves or EFB valves that require special current drive. The subtlety lies in the mechanism of selecting the current range.

Innovative current range combination logic: The output current range is not fixed in a few levels, but is selected through a set of dip switches representing different current values (± 5, 10, 20, 30, 50 mA). What's even more unique is that these switches can be selected multiple times, and the values they represent will add up. For example, by selecting both 30mA and 50mA switches simultaneously, a full-scale output range of ± 80mA can be obtained. This design provides almost continuous current range selection capability (from ± 5mA to multiple combinations in increments of 5mA, up to ± 100mA), allowing engineers to accurately match the factory calibrated rated current for each specific valve (especially the old model MFB valve), ensuring performance remains the same after replacement or commissioning.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands