GE Multilin D20/D200 Substation Controller

GE Multilin D20/D200 Substation Controller

The Multilin D20/D200 Substation Controllers offer an industry leading design embedded with high value substation automation applications that provide cost savings, increased reliability, and improved operational efficiencies in electric power substations. The ability to support a wide range of communication protocols and applications, allows the D20 to be interoperable with a broad range of intelligent electronic slave and master devices. The D20 can execute simple to complex local logic, compile and process data [collect and convert] and reports upstream to master stations. The D20’s distributed, expandable I/O architecture and mission-critical automation control applications reinforce why the D20 controller is being used in over 40,000 installations around the world.

Core functions and application scenarios

(1) Core functional positioning

As a substation level controller, D20/D200 plays three major roles: data centralization, protocol conversion, and local automation control. Its specific functions are as follows:

Data Concentrator: Automatically collects data from intelligent electronic devices (IEDs) such as relay protection devices and electricity meters, integrates it, and uploads it to SCADA, EMS, DMS, or historical databases to reduce the complexity of individual communication between multiple devices;

Protocol Converter: Supports over 100 communication protocols (including IEC 60870-5-101/103, Modbus, DNP3.0, etc.), enabling protocol translation between IEDs from different manufacturers and solving the problem of "protocol silos";

Local Automation Platform: Run customized control logic and support typical substation automation applications:

Distribution automation: capacitor group control, load transfer, fault location and isolation, voltage loss recovery;

Transmission/Generation Automation: Automatic Voltage Control (AVC), Transformer Tap Position Monitoring, Load Switching, Bus Switching Operation Interlocking;

Event recording: Local logs of sequence events (SOE) with millisecond accuracy, and storage of analog historical data for up to 7 days.

(2) The core difference between D20 and D200

The architecture of the two controllers is consistent, with the main difference being their hardware scalability to meet the needs of substations of different scales

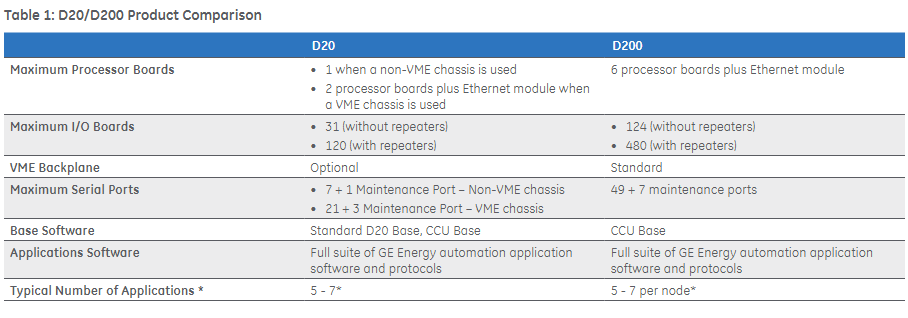

Comparison Dimension D20 Controller D200 Controller

Maximum processor board non VME chassis: 1 piece; VME chassis: 2 pieces (including Ethernet module) VME chassis: 6 pieces (including Ethernet module)

Maximum I/O board without repeaters: 31 pieces; With repeater: 120 pieces without repeater: 124 pieces; With repeater: 480 pieces

Maximum serial port non VME chassis: 7 (including 1 maintenance port); VME chassis: 21 (including 3 maintenance ports) and 49 (including 7 maintenance ports), supporting more SCADA master stations and IED access

VME backplane can be optionally equipped as standard (high scalability architecture foundation)

Typical application scenarios include small substations, distribution feeder automation, single interval monitoring of large hub substations, multi interval centralized control, and complex automation logic (such as multi station collaborative load transfer)

Hardware architecture and components

(1) Hardware topology and chassis type

Both controllers are based on modular VME architecture (D20 optional non VME single slot chassis), with core hardware including processor board, I/O module, power supply, modem, and base. The specific architecture is as follows:

Chassis type:

D20 non VME chassis: 3U single slot design, only supports 1 D20ME processor board, rear mounted terminal board provides power and serial port interface;

D20 VME chassis: 3U five slot design, supports 2 processor boards+Ethernet modules, optional rack mounted serial port panel expansion;

D200 VME chassis: 9U multi slot design, supports 6 processor boards and Ethernet modules, comes standard with redundant power interfaces, and is suitable for the multi bay requirements of large substations.

Core hardware components:

Processor board: D20ME/D20ME II, 32-bit 68030 processor (40 MHz), including 2MB Flash, 2MB SRAM (512KB battery backup), supporting RS-232/RS-485 serial ports (7 per board);

I/O module: covering discrete and analog input and output, supporting 300V DC high voltage signals, core models include:

D20S: 64 channel status input module;

D20A: 32 channel DC analog input module;

D20K: 32 channel control output module;

D20C: 16 inputs+8 outputs (optional 16 analog inputs or 8 inputs and 8 outputs analog);

Power module: Switching power supply, supports wide voltage input (20~60V DC or 100~300V DC/85~264V AC), outputs including+5V, ± 12V, 24V/48V DC, with a maximum power consumption of 7W;

Modems: Supports dial-up/dedicated mode, including WESDAC 202/V.23 (1200 bps), Telenetics series (up to 57.6 kbps), providing 1500V line isolation and lightning protection.

(2) Environmental and Safety Compliance

The hardware design meets the requirements of harsh environments in substations, and the compliance is as follows:

Environmental adaptability: working temperature -20~70 ℃, storage temperature -40~70 ℃, humidity 5%~95% (no condensation), altitude -300~3000m, anti vibration 0.75g @ 5~500Hz;

Electromagnetic compatibility (EMC): compliant with IEC 61326-1 Class A, CISPR 11 standards, anti-static discharge (± 8kV air discharge), fast transient (± 4kV), surge (± 2kV communication port);

Safety certification: UL/UL-C Class I Division 2 Groups A-D (temperature code T4), IEC 60255 insulation test (1500V DC), classification society certification (ABS, BV).

Software Tools and Configuration

(1) Core configuration tool

GE provides three types of software tools that cover the entire process of configuration, maintenance, and debugging:

SGConfig: a mainstream configuration tool that supports Windows 7 (32/64 bit) and XP, replacing the old version of Config Pro. Its features include:

Import/export XML format device configuration;

Visualize hardware topology and software application configuration;

Encrypt Ethernet transmission configuration files (supporting D20MX processors);

Config Pro: Old version tool (requires Windows XP), used for early D20 models, supports hardware parameter configuration and application download;

Maintenance tools:

WESMAINT: The controller has a built-in maintenance interface that allows users to view digital/analog status, error logs, and SOE data through a PC or VT100 terminal, and supports on-site debugging;

PROMAINT: A specialized maintenance tool for I/O modules that can force output signals to verify module functionality;

68K Monitor: Debugging tool that supports memory read and write, breakpoint setting, and serial loopback testing.

(2) Core software applications

The controller is equipped with multiple types of automation application modules and supports IEC 61131-3 standard PLC logic (LogicLinx module). The core applications include:

Data processing: analog averaging, data change detection, alarm priority sorting, redundant I/O switching;

Time synchronization: Supports IRIG-B code and SNTP protocol, achieving millisecond level synchronization of multiple controllers;

Communication management: Communication watchdog (monitoring link health), virtual terminal (remote access device), LAN services (TFTP, time server).

Communication Protocol and Compatibility

(1) Scope of Support Agreement

Host Protocols: Suitable for SCADA/EMS systems, including DNP3.0, IEC 60870-5-101, Modbus RTU/TCP, GE Private D.20 protocols;

IED Protocol (Slave Protocols): Covering mainstream power equipment, the core includes:

Protection device: SEL gateway SIPROTEC、Hydran;

Instruments: Power Measurement 3710, Rugby clock, Fluke temperature recorder;

Other: Modbus, IEC 60870-5-103, UCA 2.0;

Special features: Supports HART protocol compatibility (high impedance design, does not interfere with HART signals), GPS time synchronization (SOE accuracy 1ms).

Ordering and spare parts information

(1) Ordering Rules

The controller adopts the "basic model+configuration options" ordering mode, and the core parameters include:

Chassis type: Non VME single slot (D20), VME multi slot (D20/D200);

Processor board: D20ME (RS-232 only), D20ME II (RS-232/RS-485 optional);

Power module: Select according to input voltage and output voltage (e.g. D20ME-S-A-U-U: 20-60V DC input, 24V output);

Modems: Select according to communication method (dial-up/dedicated line) and speed;

I/O module: Combine discrete/analog modules as needed, paying attention to channel isolation requirements.

(2) Spare parts and replacements

Provide a complete spare parts system, including processor board, power supply, I/O module, modem. Old models (such as 580-2004 power supply) can be replaced with new models (D20ME-S-A-U-U), and the conformal coating version (suffix - CC) is suitable for high humidity and high dust environments.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands