How to install and maintain the Bently Nevada 3500 monitoring system rack?

Core advantage: Enhanced operator information (providing multi-dimensional data, Windows) ® Basic display software, better integration of factory control computers (multi protocol communication gateway, time synchronization data), reduced installation and maintenance costs (reduced wiring, backward compatibility, easy configuration), improved reliability (redundant power supply, TMR system), intrinsic safety options, multiple output interfaces (supporting multiple display and control systems).

Bently Nevada 3500 Monitoring System Rack Installation and Maintenance

Receiving and Processing Instructions

Receiving inspection

Visually inspect the system for any obvious transportation damage. If there is any damage, file a claim with the carrier and submit a copy to Bently Nevada, LLC.

Handling and storage precautions

The circuit board is susceptible to static damage and requires the use of a grounding strap (such as 3M Velostat) before operation ® No.2060) Grounding: Avoid using tools/materials that are prone to static electricity, such as ungrounded soldering irons and non-conductive plastics.

Transport and storage of circuit boards require the use of conductive bags or foil, and special attention should be paid to static electricity accumulation in dry weather (humidity<30%).

When the system loses power, it will lose its mechanical protection function; When operating correctly, the module can be plugged in and out while powered on (see Chapter 4 for details).

Basic Information

System Overview

The 3500 monitoring system is used to continuously monitor the status of rotating and reciprocating machinery (such as imbalance, misalignment, shaft cracks, bearing failures, etc.) to improve factory safety, product quality, equipment availability, and reduce operating costs.

Core advantage: Enhanced operator information (providing multi-dimensional data, Windows) ® Basic display software, better integration of factory control computers (multi protocol communication gateway, time synchronization data), reduced installation and maintenance costs (reduced wiring, backward compatibility, easy configuration), improved reliability (redundant power supply, TMR system), intrinsic safety options, multiple output interfaces (supporting multiple display and control systems).

General characteristics

Hot swappable module: When operated correctly, any module can be plugged in and out while the system is powered on, without affecting the operation of unrelated modules (plugging in and out of the power supply does not interrupt the system when dual power is available).

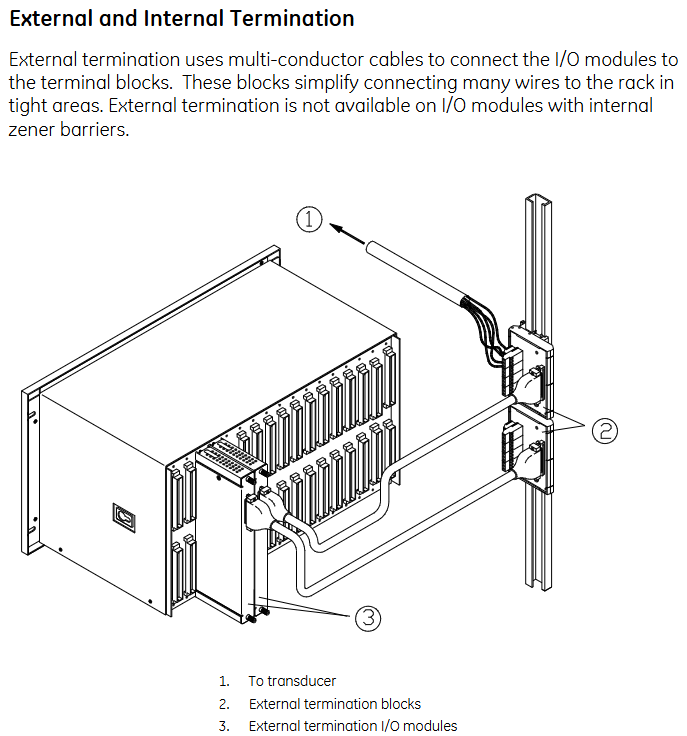

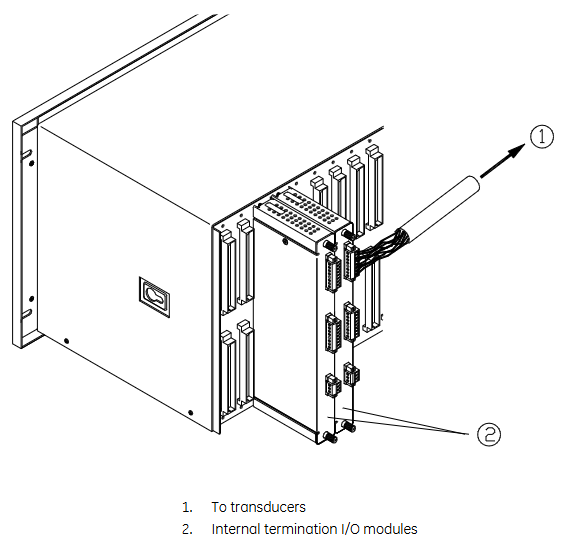

Internal and external terminals: External terminals are connected to I/O modules and terminal blocks through multi-core cables (suitable for narrow space areas); Internal terminals allow sensors to be directly connected to I/O modules (I/O modules with internal Zener barriers have no external terminals).

System components

Including a weatherproof enclosure (protecting the rack from moisture and dust), rack (full-size 19 inch/compact 12 inch Mini rack), power supply (half height module, supporting 1-2 redundant installations), Rack Interface Module (RIM, communicating with the host and other modules, maintaining event lists), communication gateway module (allowing external devices to access information), monitoring module (collecting sensor data), relay module (controlling relays based on channel status) Keyphasor ® Modules (supplying power to sensors and processing signals), display modules (supporting multiple display devices), grounding modules (providing low impedance grounding, used in conjunction with internal barrier I/O modules), etc.

Relays and Safety Systems

Standard rack relay options: independent relay (each monitoring module is equipped with more than one relay module), bus relay (multiple monitoring channels share a single relay), Triple Modular Redundancy (TMR) system (high reliability configuration, triple redundancy function, avoiding single point failure).

Intrinsic safety internal barrier system: suitable for hazardous environments, needs to be used in conjunction with grounding modules, has strict installation restrictions (such as prohibiting the use of bus sensors, requiring isolation of RS-232 connections, etc.), and has characteristics such as dual IS grounding and safe/hazardous area wiring separation.

Initial rack installation

General installation process

Refer to the installation checklist (confirm conditions such as power supply, space, ventilation, grounding, etc.);

Install weatherproof casing (if required);

Install the rack;

Set rack jumpers and switches;

Install external terminal blocks (if necessary);

Install modules;

Connect sensors, relays, and power wiring;

Complete the software configuration for rack installation.

Key installation details

Weather resistant enclosure: Meets NEMA 4 requirements, not compatible with display units; Attention should be paid to temperature derating (due to limited ventilation), panel cut size, conduit fittings (to avoid mixing power and signal wiring), and air purification options (to meet specific pressure and flow requirements).

Rack installation: Ensure ventilation (minimum gap of 50.4mm between top and bottom), support panel installation, rack installation (19 inch EIA cabinet), Bulkhead installation, etc. Different installation types have specific size and fixing requirements.

Intrinsic safety operation: Ensure that the grounding resistance is less than 1 Ω, use 4-10mm ² cables to connect to the factory's IS grounding, and use a single point grounding to avoid loops.

High electromagnetic noise/CE installation: The system rack, EMI shielding, and cables must be thoroughly grounded to shield all wiring out of the metal cabinet. CE installation must comply with EN61000.3.2 standard.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands