ABB REM615 Motor Protection and Control

Compact design: adopting a withdrawable unit structure, suitable for compact space installation.

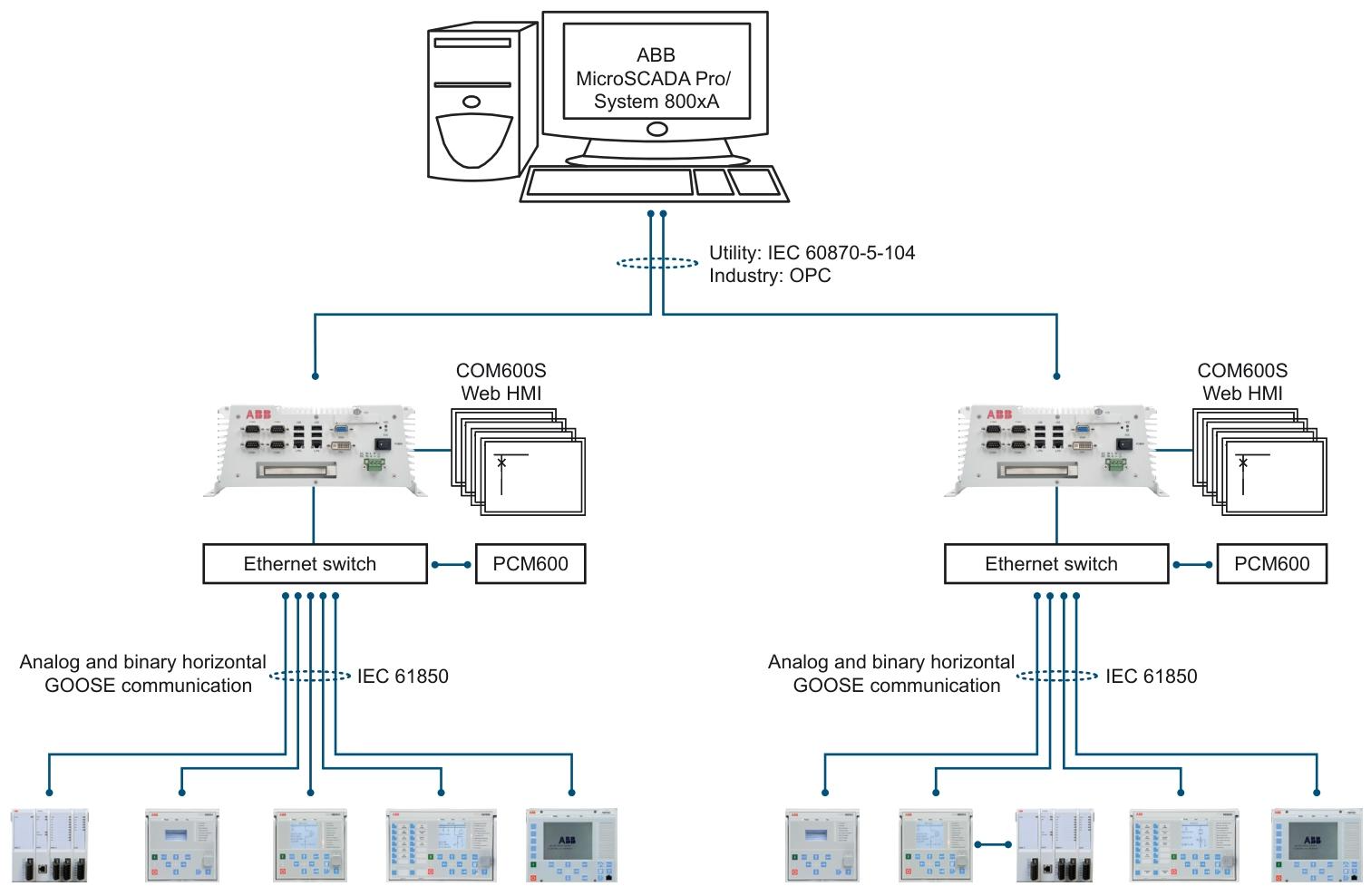

Communication standardization: fully supports IEC 61850 standard (including Edition 2), compatible with process bus IEC 61850-9-2 LE, and also supports IEC 60870-5-103, Modbus ®、 DNP3 and other protocols can support Profibus DPV1 through the protocol converter SPA-ZC 302.

Flexible configuration: Provides four standard configurations (A, B, C, D), which can be customized through the graphical signal matrix and application configuration function of PCM600 tool to meet specific user needs.

ABB REM615 Motor Protection and Control

Product Overview

REM615 is ABB Relion ® The dedicated motor protection and control relay in the 615 series is designed specifically for the protection, control, measurement, and monitoring of asynchronous motors in the industrial field. Its characteristics include:

Compact design: adopting a withdrawable unit structure, suitable for compact space installation.

Communication standardization: fully supports IEC 61850 standard (including Edition 2), compatible with process bus IEC 61850-9-2 LE, and also supports IEC 60870-5-103, Modbus ®、 DNP3 and other protocols can support Profibus DPV1 through the protocol converter SPA-ZC 302.

Flexible configuration: Provides four standard configurations (A, B, C, D), which can be customized through the graphical signal matrix and application configuration function of PCM600 tool to meet specific user needs.

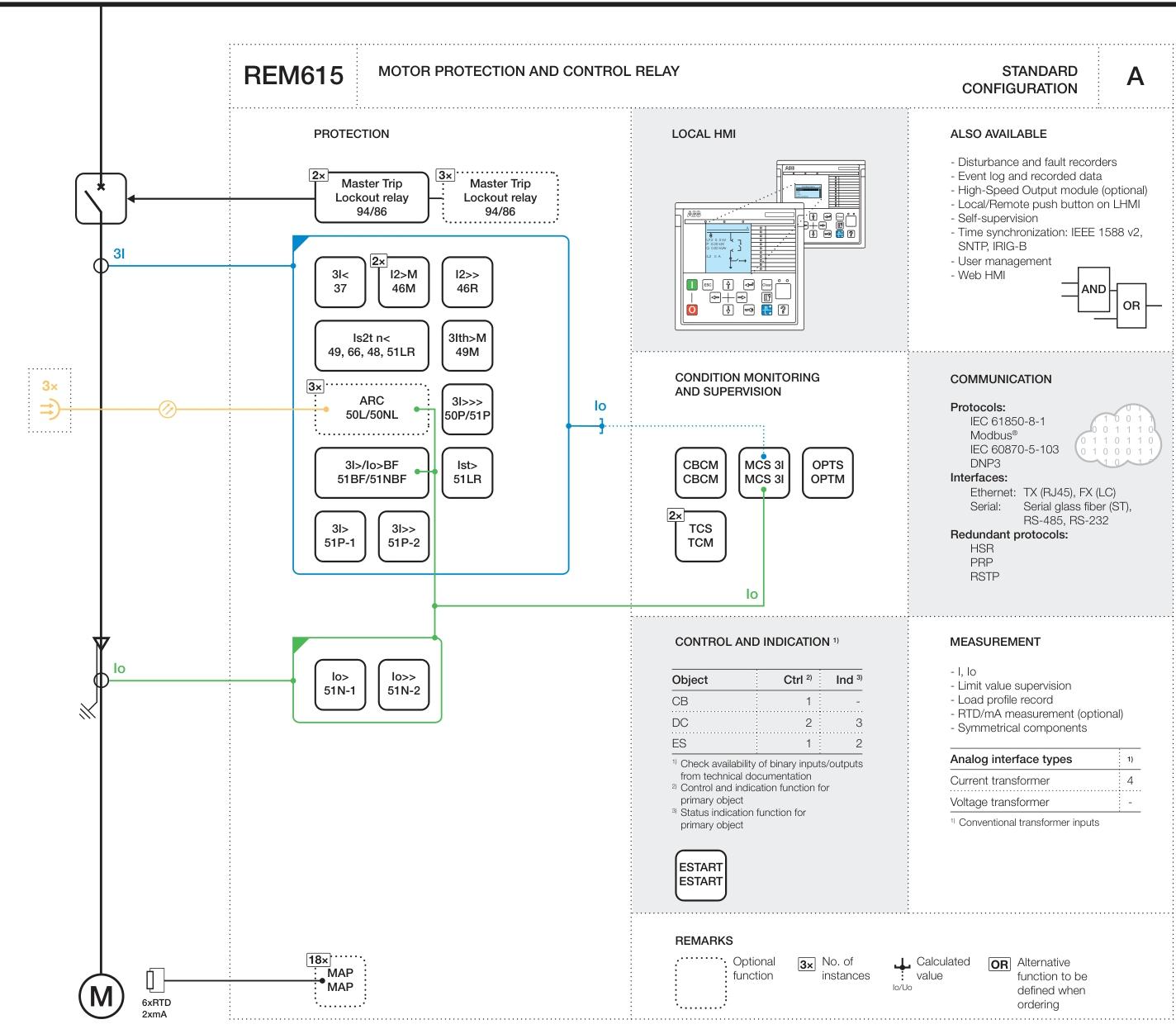

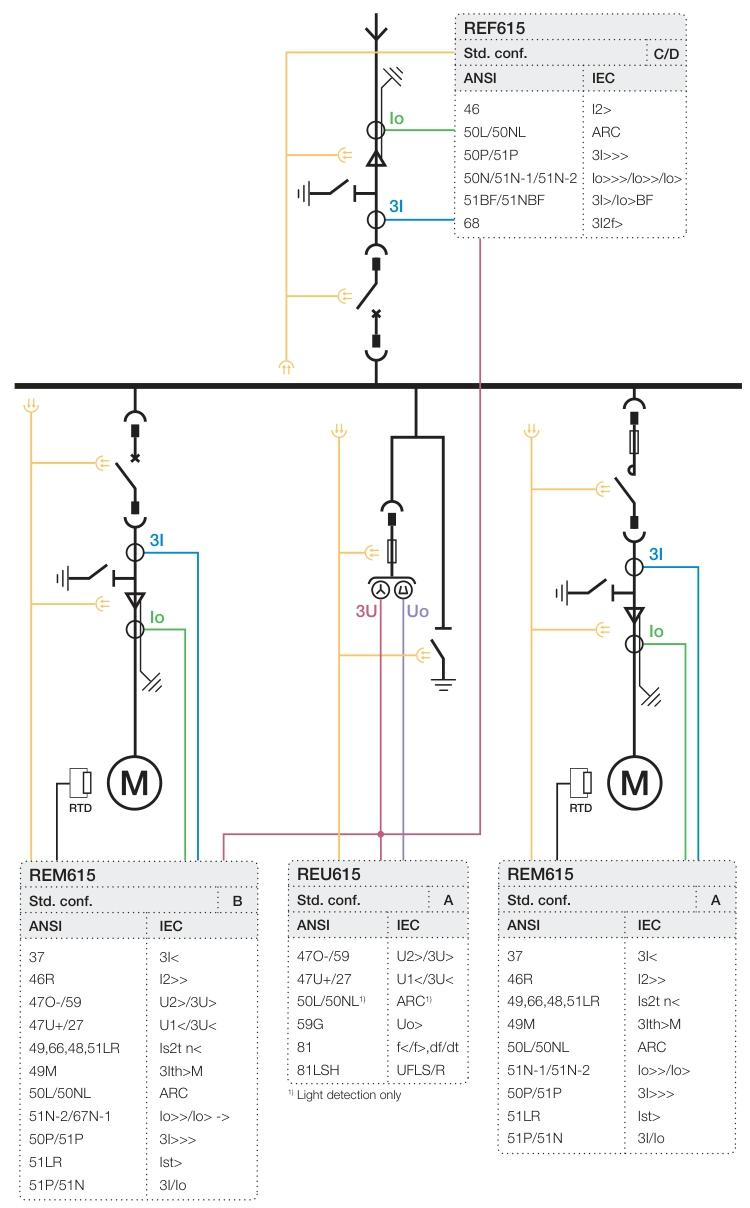

Standard configuration

The core differences and applicable scenarios of the four standard configurations are as follows:

Applicable scenarios for configuring core functions

A basic motor protection (including RTD temperature measurement option), including overcurrent, thermal overload, negative sequence overcurrent and other motors that only require basic protection, such as small pumps and fans

B adds voltage and frequency protection and measurement on the basis of A, supporting RTD temperature measurement for motors that require voltage/frequency monitoring, such as medium-sized compressors

C includes voltage and frequency protection and measurement, without RTD option for industrial motors with low temperature monitoring requirements

D supports voltage and frequency protection, using sensor inputs (instead of traditional CT/VT) to adapt to compact switchgear (such as ABB UniGear Digital) motors

All configurations include basic functions such as fault recording, event logging, self-monitoring, and can be expanded with options such as high-speed output module (HSO) and arc protection according to requirements.

Core functions

Protection function

Overcurrent protection: including three-stage non directional overcurrent (low/high/instantaneous), zero sequence overcurrent, covering motor short circuits and ground faults.

Motor specific protection: thermal overload protection (MPTTR), locked rotor protection (JAMPTOC), start-up monitoring (STTPMSU), phase sequence protection (PREVPTOC), etc., suitable for the entire life cycle of motor start-up and operation.

Voltage and frequency protection: under voltage (PHPTV), negative sequence overvoltage (NSPTOV), frequency anomaly (FRPFRQ), etc., to cope with voltage/frequency fluctuations in the power grid.

Enhanced protection: Optional arc protection (ARCSARC) can be used to quickly detect arc faults through light sensors, reducing equipment damage; Circuit breaker failure protection (CCBRBRF) ensures reliable fault removal.

Control function

Support local/remote control of circuit breakers, isolating switches, and grounding switches, using a "select execute" mechanism to ensure operational safety.

Integrated Emergency Start Function (ESMGAPC) allows for forced start of hot state motors to adapt to emergency conditions.

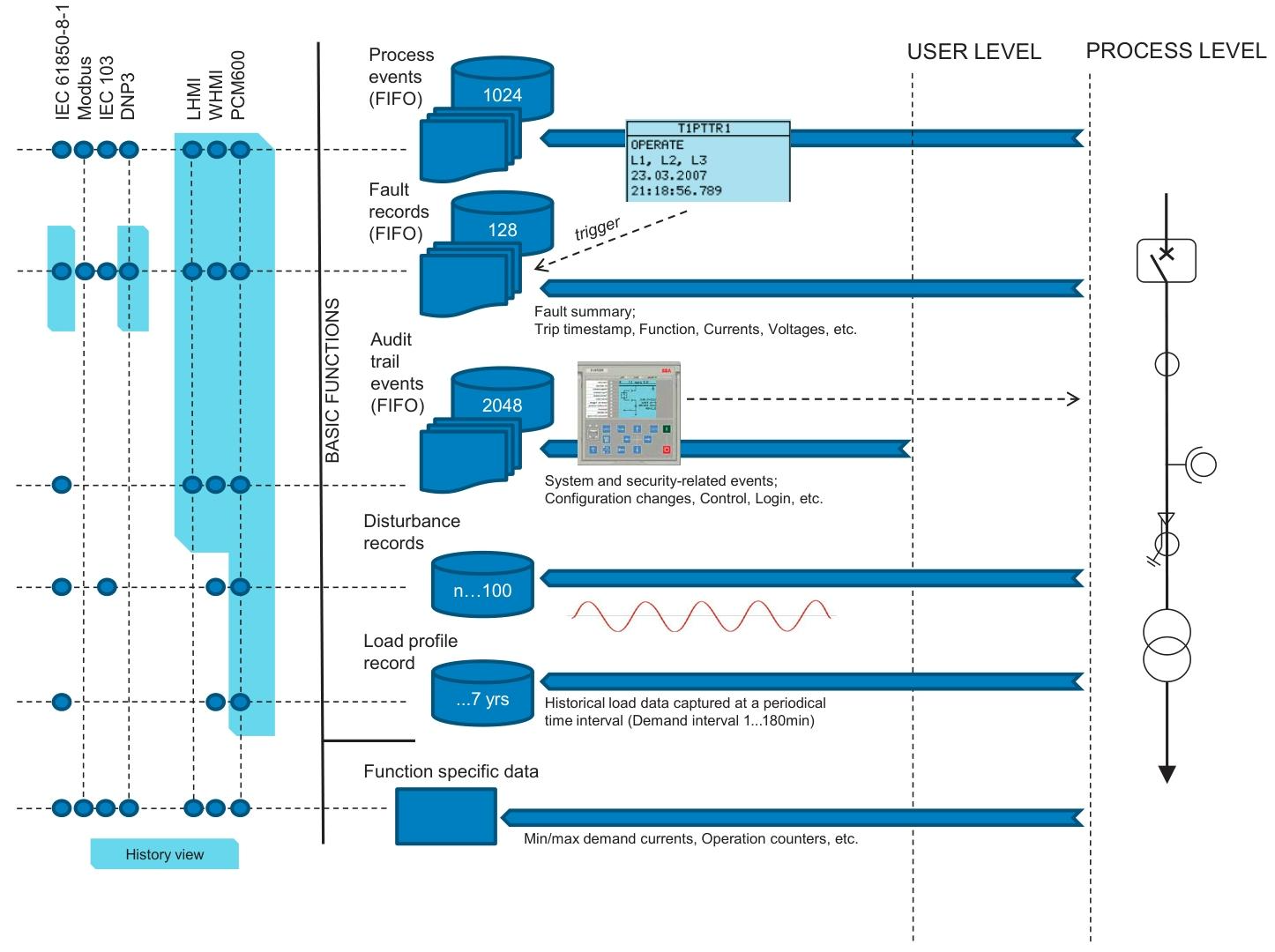

Measurement and Monitoring

Real time measurement of electrical quantities such as current, voltage, power, frequency, etc., with an accuracy of ± 0.5% (current/voltage).

Status monitoring: Circuit breaker status (SSCBR), trip circuit monitoring (TCSSCBR), current circuit monitoring (CCSPVC), etc., supporting preventive maintenance.

Wave recording and logging: The disturbance recorder can record 12 analog signals and 64 switch signals. The event log stores 1024 events (with timestamps) and supports post fault analysis.

Communication and synchronization

Network redundancy: Supports redundant protocols such as HSR, PRP, RSTP, etc. to ensure communication reliability.

Time synchronization: Supports IEEE 1588 v2 (accuracy 4 µ s), SNTP, IRIG-B, and meets the time synchronization requirements of process buses.

Technical parameters

Power supply: Supports AC 100-240V or DC 24-250V, power consumption ≤ 21W.

Input/output:

Analog input: CT rated 1A/5A, VT rated 60-210V AC; Configuration D supports sensor input (75mV-9V).

Binary input: 24-250V DC, response time<3ms; output contact capacity up to 30A (short-term).

Environmental adaptability: Working temperature -25~+55 ℃, protection level IP54 (front)/IP20 (back), anti electromagnetic interference in accordance with IEC 61000-4 series standards.

Installation and Configuration

Installation method: Supports embedded, semi embedded, and 19 inch rack installation, compatible with various switchgear.

Configuration tool: Parameter setting, logic configuration, and graphical display editing can be performed through PCM600 software, and remote access to Web HMI is supported (must be enabled).

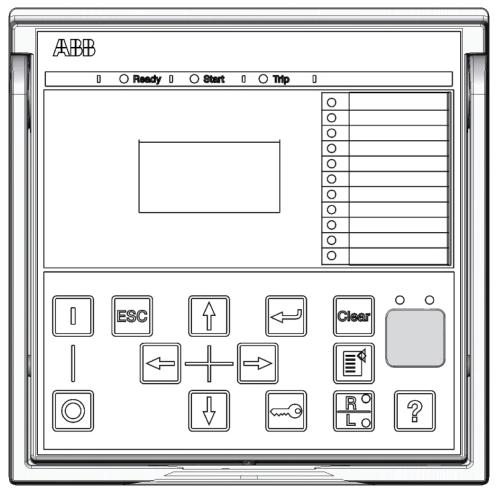

Human machine interface: Provides two sizes of LCD displays, with the large display supporting custom single line diagrams (SLDs) to visually display device status.

Application scenarios

Mainly used for asynchronous motor protection in the industrial field, including:

Rotating equipment such as pumps, fans, compressors, etc;

Heavy industrial motors such as crushers and mixers;

Suitable for medium voltage motors in compact switchgear.

Flexible configuration can meet the motor protection requirements of different voltage levels (medium and low voltage) and different operating conditions (continuous operation/intermittent start).

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands