REXROTH 4WRPEH series Directional control valves

REXROTH 4WRPEH series proportional directional valve: an Industry 4.0 solution that integrates intelligence and precise control

Product positioning and technological innovation

In the wave of modern industrial automation transforming towards intelligence and networking, hydraulic control technology has also undergone profound changes. The 4WRPEH series proportional directional valve launched by Bosch Rexroth is an outstanding representative of this trend. As a direct operated directional control valve with electrical position feedback and integrated electronic devices (On Board Electronics, OBE), it integrates traditional high-performance hydraulic technology with modern digital communication, intelligent diagnosis, and safety functions, providing a new solution for precise closed-loop control of position, speed, and pressure.

The 4WRPEH valve belongs to the 10 port, 3X component series, and its core design philosophy revolves around reliability, safety, energy efficiency, high quality, flexibility, and precision. The most eye-catching feature is its optional IO Link interface, which not only makes it an intelligent component that complies with Industry 4.0 (I4.0) standards, but also achieves a safety shutdown function that complies with EN 13849-1 standards and can reach up to Category 3, Performance Level (PL) d through specific configurations, paving the way for building a safety integrated machine control system.

Interpretation of Core Technical Characteristics and Models

1. Core components and structure

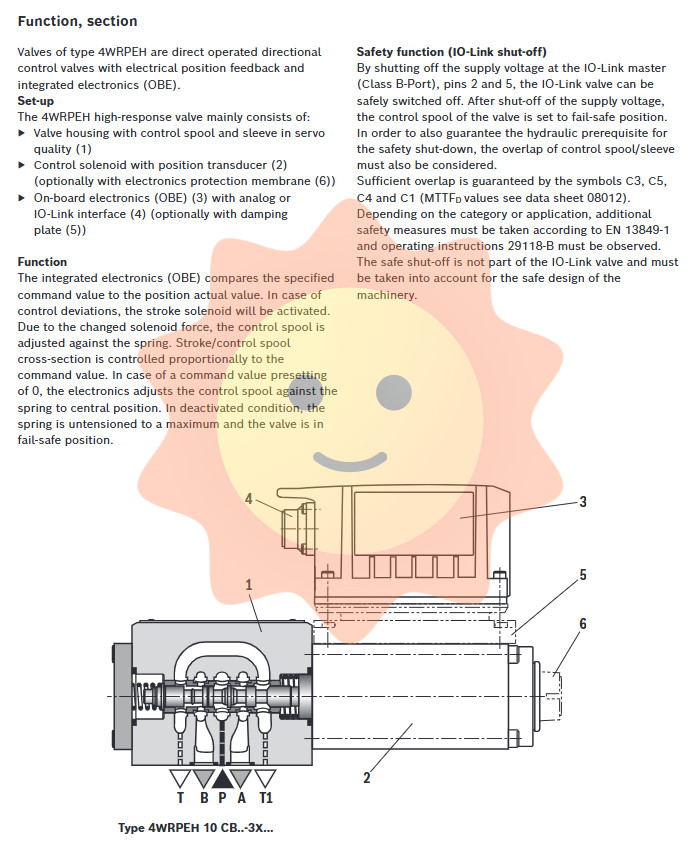

The 4WRPEH valve is essentially an electro-hydraulic proportional valve, and its core structure includes:

Servo quality valve core and sleeve (1): High precision matching valve core and sleeve are used to ensure extremely low hysteresis (≤ 0.2%) and excellent repeatability, which is the foundation for achieving high dynamic response and precision control.

Control electromagnet with position sensor (2): Built in non-contact position sensor, providing real-time and accurate feedback of the actual displacement of the valve core, forming the core feedback loop of closed-loop control.

Integrated Electronic Device (OBE) (3): This is the "brain" of the valve, integrating signal processing, power amplification, closed-loop control algorithms, and communication interfaces. It directly compares the instruction value with the actual value of the valve core position and drives the electromagnet.

Communication interface (4): Multiple interfaces can be selected, including analog (± 10V, 4-20mA) and digital (IO Link), to meet the access requirements of different control systems.

2. Model code and key options

The ordering code system defines all key parameters of the valve, which is the basis for correct selection. Taking code 4WRPEH 10 B 50 L 3X M 24 L1 as an example:

Valve core function (6th and 7th digit codes): such as "C3", "C5", "C1", etc., define the connection relationship between oil ports P, A, B, and T at different valve core positions. This is the core of selecting control logic (such as median function).

Rated flow rate (8th code): defined when the pressure difference Δ p on a single control edge is 35 bar, with two options: 50 L/min and 100 L/min. The flow rate follows the square root relationship formula with the change of pressure difference:

qx=qVnom⋅Δpx35q x=q Vnom⋅ 35Δp x

Traffic characteristics (9th code):

L-type (linear): The displacement of the valve core is linearly related to the output flow rate, suitable for applications that require linear speed control.

P-type (inflection point characteristic): There is an inflection point at about 40% of the spool stroke, with lower gain near zero position, providing finer micro motion control, and higher gain in high flow area, suitable for situations requiring fine low-speed control and fast high-speed response.

Sealing material (11th digit code): NBR (nitrile rubber) or FKM (fluororubber), the choice depends on the compatibility of the hydraulic oil used.

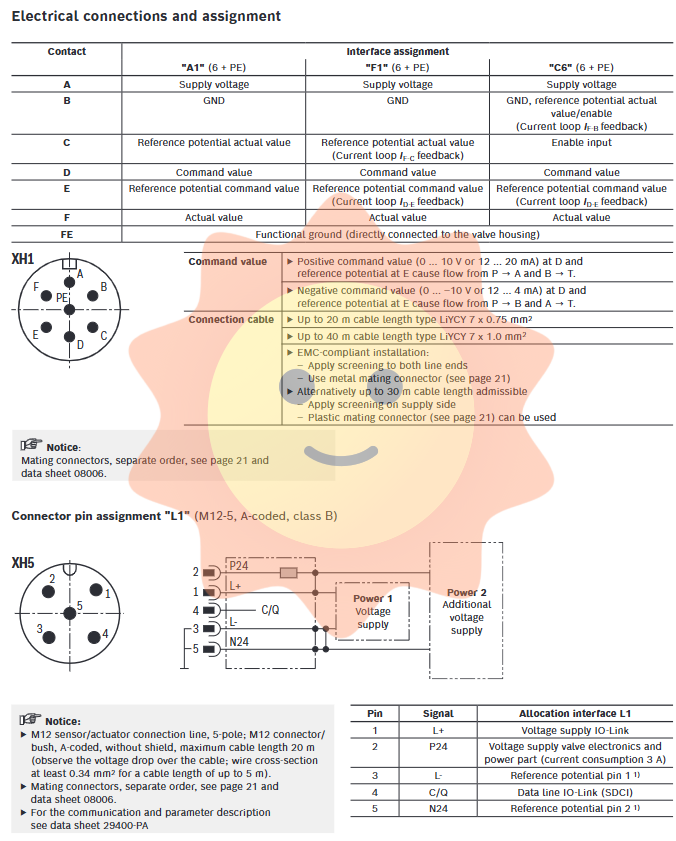

Electronic interface (14th code): This is the key to the level of intelligence.

A1: Analog voltage command input (± 10V), analog voltage actual value output (± 10V).

F1: Analog current command input (4-20mA), analog current actual value output (4-20mA).

L1: IO Link digital communication interface. This is the core of implementing Industry 4.0 integration, supporting parameter settings, status monitoring, diagnostic data reading, and firmware updates.

C6: Combination interface (± 10mA instruction, 4-20mA actual value, with enable signal).

Electronic protective film (15th digit code "967"): Recommended for use in high environmental humidity or severe cyclic temperature changes (such as outdoor applications) to prevent condensation from forming inside the electronic compartment.

Working principle and advanced functions

1. Closed loop proportional control

OBE receives command signals (analog voltage/current or IO Link digital commands) from the controller and compares them with the actual value of the spool position sensor. Once a control deviation occurs, OBE will immediately adjust the current output to the control electromagnet, thereby changing the electromagnetic force. This electromagnetic force opposes the reset spring, driving the valve core to move precisely to a position proportional to the command value, thereby infinitely adjusting the flow rate through the valve port. When the command value is zero, the electronic device adjusts the valve core to the neutral position. When the power is cut off, the spring is fully released and the valve core enters the fault safe position.

2. IO Link Integration and Security Shutdown

The IO Link interface (L1 type) is not only a digital communication channel that replaces analog signals, but also brings revolutionary features:

Parameterization and diagnosis: All valve parameters, such as gain and ramp time, can be easily set and saved through software. Can read detailed diagnostic data, such as temperature, current, fault codes, etc.

Safe shutdown: By cutting off the power supply to pins 2 and 5 of the IO Link master station (Class B port), the valve can be safely closed and placed in a fail safe position. Combined with valve cores with sufficient coverage (such as C3, C5, C4, C1 types), this function can be used to construct safety related control circuits that comply with EN 13849-1 standards, up to Category 3, PL d. Machine manufacturers need to implement additional safety measures and periodic diagnostics according to standards.

Internal fault monitoring: OBE continuously monitors its own status. When low power supply voltage, IO Link communication interruption, watchdog timeout, or internal error is detected, the electromagnetic power supply will be automatically cut off, allowing the valve to enter the fault safe position.

3. Damping plate and protection

Damping plate "D": an optional accessory used to suppress high-frequency vibrations (>300 Hz) transmitted externally to the valve and protect internal precision electronic components. However, it is not recommended to use it for applications primarily subjected to low-frequency excitation (<300 Hz).

Electronic protective film "967": As mentioned earlier, it is used in harsh environments to prevent condensation.

Detailed technical data and performance boundaries

1. Hydraulic and medium conditions

Maximum working pressure: A, B, P ports: 350 bar; T port: 250 bar.

Hydraulic oil: compatible with mineral oil (HL, HLP), biodegradable oil (HETG, HEES, HEPG), and flame retardant hydraulic fluid (HFC, HFDU). The selection of oil directly affects the sealing compatibility, temperature range, and component life, and strict reference to the compatibility table is required.

Oil cleanliness: extremely high requirements, must meet ISO 4406 18/16/13 level. This is the key to ensuring long lifespan and reliability.

Usage restrictions: To ensure reliable fault safety functions, different valve core functions have limitations on the working pressure difference (350 bar for C3 and C5 models; C1 and C4 models are 250 bar).

2. Electrical characteristics

Power supply: All electronic interfaces require a 24 VDC power supply, with slightly different allowable ranges (e.g. A1/F1/C6 type: 19-36 VDC; L1 type valve amplifier: 18-30 VDC.

Protection level: When using a suitable and correctly installed docking plug, it can reach IP65.

EMC installation: To achieve electromagnetic compatibility, metal docking plugs must be used and the cable shielding layer must be grounded at both ends. If only grounded at one end, a plastic plug can be used, but the cable length is allowed to be shortened.

3. Dynamic performance and characteristic curve

The document provides detailed characteristic curves of HLP46 hydraulic oil at 40 ° C, including:

Flow signal characteristic curve: visually displays the relationship between the command signal and the flow rate between each oil port under L-shaped and P-type flow characteristics.

Step response curve: displays the response time of the valve to different amplitude command steps, reflecting its high dynamic performance.

Frequency response curve: describes the amplitude and phase response of the valve under different frequency sine signal excitations, and is the key to evaluating the dynamic stability of the system.

Leakage volume at the fault safe position: lists the internal leakage volume between each oil port in the power-off (fault safe) state, which is crucial for system pressure maintenance design.

Installation, wiring, and accessories

1. Mechanical installation

Adopting the bottom plate installation method of ISO 4401-05-04-05 standard.

Installation must be carried out using specified hexagon socket head screws (such as ISO 4762-M6x40) and specified tightening torque (such as 12.5 Nm ± 10%) to ensure sealing and pressure bearing capacity.

The installation surface must meet the specified surface processing quality.

2. Electrical connection

Analog interfaces (A1, F1, C6): Use 6-pin+PE circular connectors. The pin definition is clear, and attention should be paid to the polarity of the instruction value: positive signals cause P → A/B → T to flow; Negative signal causes P → B/A → T flow.

IO Link interface (L1): using M12-5 pin, A-code connector. Among them, Pin2 (P24) and Pin5 (N24) are the valve electronic devices and power stage power supplies; Pin1 (L+) and Pin3 (L -) provide power to the IO Link communication interface; Pin4 (C/Q) is the data cable. Pin3 and Pin5 are already connected inside the valve, and L - and N24 must also be connected together on the power supply side.

3. Recommended attachments

Docking plugs and cables: Bosch Rexroth offers a variety of prefabricated shielded cable components ranging in length from 1.5 meters to 20 meters, strongly recommended for use to ensure EMC performance.

Testing and maintenance equipment: such as a dedicated maintenance test box (R901049737), which can be used for offline testing, diagnosis, and parameter setting of valves.

Selection and Application Points

Clarify control requirements: Firstly, determine whether it is position, speed, or pressure control, as well as the requirements for dynamic response and control accuracy.

Select valve core function and flow rate: Select the neutral function (C3, C5, etc.) based on the principle of hydraulic circuit, and calculate and select the rated flow rate of 50 or 100 L/min according to the maximum flow rate of the system and the expected working pressure difference.

Determine the level of interface and intelligence: choose analog interfaces (A1, F1) for traditional PLC control, or choose IO Link interface (L1) to achieve digital, intelligent integration and advanced safety functions. If considering safety shutdown, it is necessary to choose component series 31 and above models.

Check the compatibility between the environment and the medium: confirm the compatibility of the environmental temperature, vibration conditions, and the hydraulic oil and sealing material (NBR/FKM) used. For special media such as flame retardant liquids, attention should be paid to the potential performance degradation they may cause.

Safety integration considerations: If IO Link valves are used for safety shutdown, it is necessary to strictly follow the requirements of operating manual 29118-B, conduct risk assessment, and implement necessary periodic diagnostic monitoring outside the valve to meet the target category and PL level.

System integration: Pay attention to internal leaks in the fault safe position and design the hydraulic circuit reasonably. Ensure power supply quality and configure the correct external fuse (such as 13.15A delay type).

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA