REXROTH BTV04.2 Micro Control Panel Functions and Applications

As an important hub connecting operators and machines, BTV04.2 not only provides an intuitive operating experience, but also supports communication with various Indramat controllers (such as MTC200, CLC, Ecodrive3, PPC-R, etc.) and PCs. Its hardware design balances durability and functionality, with the front panel reaching IP65 protection level, suitable for industrial site environments.

REXROTH BTV04.2 Micro Control Panel: Function Analysis and Application Guide

Product Overview and System Positioning

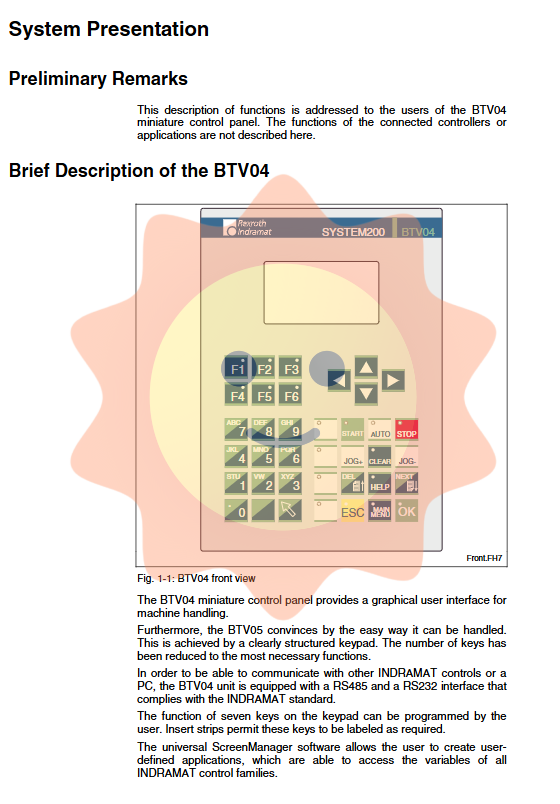

BTV04.2 is a miniature control panel launched by Rexroth Indramat, belonging to the System200 product family, designed specifically for the operation and monitoring of industrial machinery and automation equipment. This device adopts a compact structure with a graphical user interface, suitable for single axis or multi axis control systems, and is widely used in packaging machinery, food processing, machine tools, handling systems, and general automation fields.

As an important hub connecting operators and machines, BTV04.2 not only provides an intuitive operating experience, but also supports communication with various Indramat controllers (such as MTC200, CLC, Ecodrive3, PPC-R, etc.) and PCs. Its hardware design balances durability and functionality, with the front panel reaching IP65 protection level, suitable for industrial site environments.

Hardware Structure and Technical Characteristics

1. Appearance and mechanical design

BTV04.2 adopts an aluminum alloy front panel, equipped with 38 buttons, of which 7 buttons support user-defined labels (achieved through plug-in label strips). The device is equipped with a 128 × 64 pixel monochrome graphic LCD display screen, supporting LED backlight and dark mode, with a visible area of 68 × 37 mm. The overall size is 203 × 143 × 45 mm (including the installation frame of 203 × 143 × 50 mm), weighing about 1.7 kg, and the appearance is light gray (RAL7035).

2. Core hardware configuration

Processor: Based on 68000 series microcontroller

Storage: 1 MB Flash memory, 512 KB RAM

Communication interface:

COM1: RS485 interface (compliant with Indramat standard, supports bus connection)

COM2: RS232 interface (for software loading and debugging)

I/O configuration: 10 24V inputs, 11 24V outputs, all using electrical isolation design

Power supply: 24V DC (range 18-30V), maximum current consumption 400 mA

3. Environmental adaptability

BTV04.2 is suitable for industrial environments, with a working temperature range of+5 ℃ to+45 ℃ and a storage and transportation temperature range of -20 ℃ to+60 ℃. The equipment can withstand a certain degree of vibration and impact, in compliance with EN60068-2-6 standard. The front panel protection level is IP65, suitable for dust-proof and waterproof occasions; The protection level of the rear shell is IP20 and it needs to be installed in the control cabinet or protective box for use.

Safety operation standards and precautions

1. Scope of application and inapplicability

BTV04.2 is only applicable for the operation and monitoring of industrial machinery and shall not be used in the following situations:

Personnel transportation equipment (such as elevators, cranes)

High risk areas such as medical equipment, nuclear facilities, refineries, etc

Direct control of security protection system

The equipment must use the original factory specified accessories and cables, and operate under the specified electrical, mechanical, and environmental conditions.

2. Electrical safety

High voltage protection: All wiring above 50V must be operated by qualified electrical personnel and ensure reliable grounding of the equipment.

Low voltage interface: All 0-50V interfaces are designed to protect extra low voltage (PELV) and must be safely isolated from high voltage circuits (such as through isolation transformers or optocouplers).

Leakage current protection: During normal operation, the leakage current of the equipment may exceed 3.5 mA, and a copper protective wire with a cross-sectional area of not less than 10 mm ² must be used for grounding.

3. Mechanical and sports safety

Dangerous motion protection: The object controlled by the equipment may experience unexpected motion due to parameter errors, wiring faults, or sensor failures. External protective devices such as safety fences, light curtains, and emergency stop buttons must be installed.

Vertical axis safety: In the event of a power outage, the vertical axis must be prevented from falling through mechanical locking, external braking, or balancing devices.

4. Special Risk Warning

Electromagnetic field impact: During device operation, electromagnetic fields may be generated, posing a risk to users of pacemakers, hearing aids, or metal implants. Relevant personnel should avoid approaching.

High temperature surface: The surface of the equipment may be at high temperature during operation or shortly after power failure, and it needs to be cooled for at least 10 minutes before contact.

Battery and pressure system: If the equipment contains a battery or is connected to a pressure system (such as pneumatic or hydraulic), it must be operated according to specifications to avoid disassembly, short circuit, or disassembly under pressure.

Wiring and System Integration

1. Interface definition

X1 (power supply): 24V DC input, including a pair of floating relay contacts (maximum load 24V/150mA)

X2 (RS485): Used for bus communication and supports multiple device connections

X3 (RS232): Used for software loading and debugging

X4, X5 (24V I/O): Provides 10 inputs and 11 outputs, can be used for external buttons, indicator lights, etc

2. Typical Connection Examples

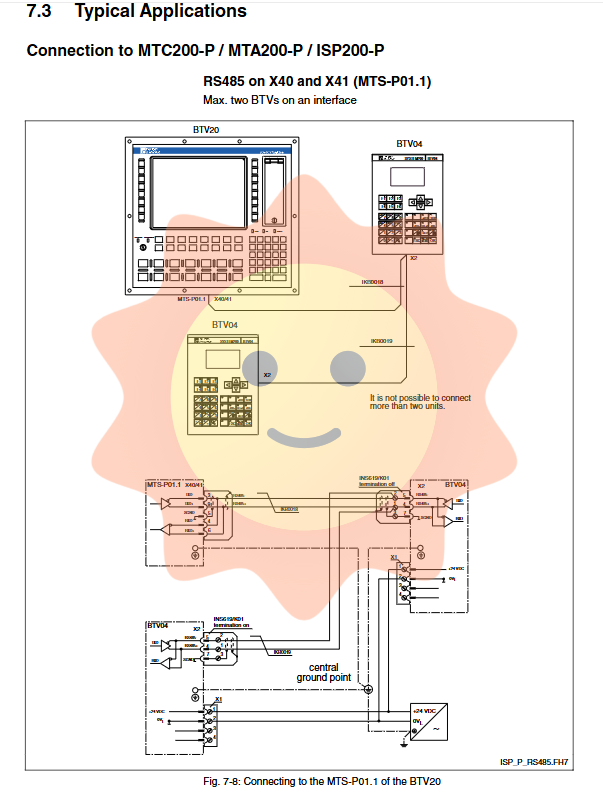

BTV04.2 can be directly connected to various Indramat controllers:

MTC200-P/MTA200-P/IS200-P: Connected via RS485 interface (X40/X41 or X16), supports up to 2 BTVs in parallel

CLC-D, Ecodrive3, ELC: connected via a single bus

PPC-R, CLM, DLC: connected via standard RS485 interface

All communication cables are recommended to use shielded twisted pair cables, with a length not exceeding 400 meters (RS485) or 10 meters (RS232), and terminal resistors should be installed at both ends of the bus if necessary.

First debugging and software loading

1. Required tools

BTV04.2 Control Panel and Power Supply

Connect cable IKB0012 (RS232 interface)

PC with "Dolfi" flash tool installed (Windows 3.11/95/98/NT)

Application software disk (including. IBF files)

2. Loading steps

Connect BTV04.2 to PC via IKB0012 cable

Power on BTV04.2, the screen displays the Indramat logo

Run Dolfi tool on PC, set COM port and baud rate (connection: 9600 bps; Download: 38400 bps) and destination address (default is 03)

Select 'Serial Connect' to establish a connection

To back up the original software, select "Backup" and save it as BAK file

Select 'Send' to load the new software, and the progress bar will display the transmission status

After completion, select 'Disconnect' and BTV04.2 will automatically restart and run the new software

3. Bootloader function

After powering on the device, first run the Bootloader to check if there is any valid software in the Flash. If there is no valid software or the software is damaged, the screen will display "dolfi loader active". At this time, you can press the F1 key to enter service mode, view version information or reload the software.

Attachments and ordering information

BTV04.2 provides a variety of matching cables and connectors, such as:

IKB0012: RS232 programming cable

IKB0017/0018/0019: RS485 communication cable (up to 400 meters long)

INS0619/K01: RS485 connector with terminal resistor

In terms of software, users can customize the interface and logic through the "ScreenManager" tool, which supports interaction with Indramat's full range of controller variables.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA