REXROTH VT-HNC100... 3X Series Digital Axis Controller

REXROTH VT-HNC100... 3X Digital Axis Controller: Comprehensive Technical Analysis and Application Guide

Product positioning and functional overview

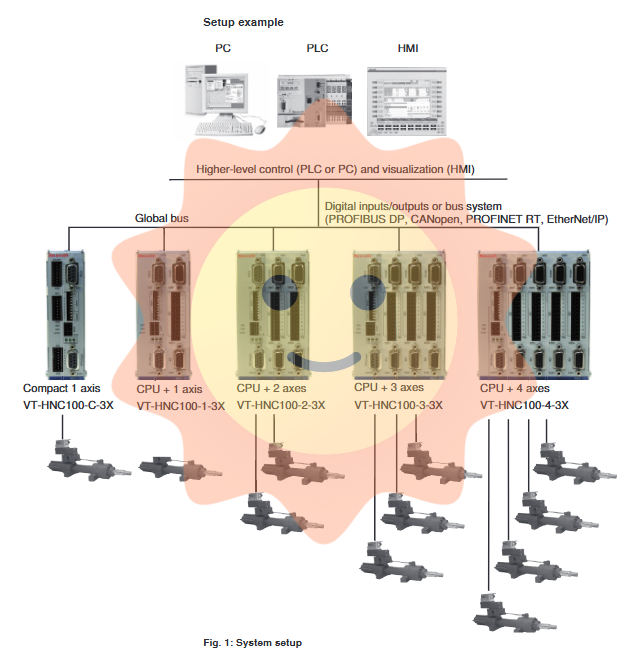

VT-HNC100... 3X is a programmable digital axis controller launched by Bosch Rexroth, belonging to the 3X series products. This controller is designed specifically for integration into industrial machines or systems, used for open-loop and closed-loop control of up to four electro-hydraulic shafts. Its core functions include position, pressure, force, speed, and differential pressure control, and can be optionally equipped with synchronous operation function. Its typical application areas include machine tools, plastic machinery, specialized machinery, presses, and conveyor systems, and it is the core component for achieving complex motion sequences and precise process control.

As a product designed for harsh industrial environments, VT-HNC100... 3X fully considers anti-interference, mechanical vibration and impact resistance, and climate adaptability in its design. The controller itself does not contain any safety functions for personnel safety, nor is it a safety related component. Its core task is to provide position, pressure, force, and speed control of the hydraulic shaft for machine functions. The complete security monitoring needs to be implemented by higher-level control logic and corresponding I/O components.

Safety regulations and intended use

1. Expected use and limitations

VT-HNC100... 3X is defined as an electrical component that can only be integrated into machines or systems for use. The product must be debugged within the machine/system designed for it and strictly adhere to the operating conditions and performance limits specified in the technical data.

It is strictly prohibited to use it in the following situations:

Explosive environment.

As a safety related control component that complies with DIN EN ISO 13849 standard.

Private use (limited to professional use only).

Any deviation from the intended use is considered as' unintended use ', and Bosch Rexroth assumes no responsibility for it. The related risks are entirely borne by the user.

2. Personnel qualification requirements

Personnel operating, installing, and maintaining VT-HNC100... 3X must possess professional knowledge in electrical installation, control technology, programming, and hydraulic aspects, and understand relevant technical terms. All work must be carried out by qualified technical personnel or under the supervision and guidance of qualified personnel. In addition, operators need to be proficient in PC software WIN-PED ® The use of. Bosch Rexroth strongly recommends that users participate in the product specific training it provides.

3. General safety instructions

Dangerous movement protection: Personnel are not allowed to stay within the range of machine movement. It is necessary to prevent personnel from accidentally entering hazardous areas through measures such as guardrails, protective nets, protective covers, or light curtains.

Electrical safety: All 0-50V connections must use protective extra low voltage (PELV) and be safely isolated from hazardous voltage circuits (such as through isolation transformers, safety optocouplers, or battery power supply).

Product liability: The application cases and recommendations provided by the manufacturer are for reference only. Machine manufacturers or system integrators must independently verify the applicability of the provided components based on their specific safety regulations and standards, and take all necessary measures.

Hardware architecture and technical specifications

1. Product identification and version

The product model is accurately identified through the order code, and the code structure reflects the key configuration:

Axis number: C (compact), 1, 2, 3, 4 axis versions.

Bus type: Supports PROFIBUS DP, CANopen, and PROFINET RT or EtherNet/IP with Ethernet functionality. The PROFIBUS DP version can also be optionally equipped with a TCP/IP service interface.

Firmware and software: Hardware with Ethernet interface (starting from Series 31) requires WIN-PED ® 7 and above versions and firmware 7.05.02 or higher.

2. Core hardware and interfaces

The controller provides rich interfaces to connect sensors, actuators, and higher-level control systems:

Universal interface (all versions):

X1S: Power interface (18-30 V DC).

X3C: RS232 interface, used to connect PC and software WIN-PED ® Parameterize and diagnose.

Bus interface: configured according to the model as X7P (PROFIBUS DP), X7C (CANopen), or X7E1/X7E2 (PROFINET RT/EtherNet/IP).

Axis related interfaces (multi axis versions allocated by slot):

X8M (Encoder): Encoder interface, supporting incremental and SSI absolute encoders, providing+5V,+10Vref, or+24V encoder power supply.

X2A (AIO): Analog input/output interface. Supports 2 analog inputs (Vin), 2 current inputs (Cin), 2 analog outputs (Vout), and 1 current output (Cout), and provides a+24V induction power supply (Vens) for the sensor.

X2D (DIO): Digital input/output interface. Provide up to 11 freely configurable digital I/O points.

Important reminder: The pins marked as "reserved" in the pin allocation diagram are strictly prohibited from being connected.

3. Status indicator lights (LEDs)

The front panel provides clear operational status indicators:

3.3 V: The internal voltage supply of the controller is normal.

RUN: The controller has been initialized and is in the 'running' state. Flashing indicates that it has not been initialized.

BUS: The fieldbus communication is normal.

For PROFINET RT/EtherNet/IP models, additional services are provided:

NS (Network Status): Indicates IP address allocation and connection status.

MS (HACD status): Indicates high availability consistency domain status.

L (Link): Indicates the active connection with the communication partner.

S (transmission status): Flashing indicates sending/receiving Ethernet messages.

System Integration and Interface Detailed Explanation

1. Mechanical installation

VT-HNC100... 3X is designed for installation on top cap rails (DIN rails) inside control cabinets. By inserting the controller casing into the conductive mounting rail, a ground connection can be established with the control cabinet backplane to achieve high-frequency (HF) grounding.

Installation environment: It must meet the environmental conditions specified in data manual RE 30139, avoid conductive pollutants (acid, alkali, salt, metal vapor, etc.), and ensure compliance with IP20 protection level.

Attention: The equipment casing has perforations. During installation and operation, it is necessary to ensure a clean environment to prevent liquids and dirt from entering and causing short circuits.

2. Electrical wiring and EMC specifications

Correct wiring is crucial for system stability and anti-interference:

Power supply: Try to shorten the power line (+24V/GND) as much as possible and ensure that the power supply and return lines are wired in parallel.

Shielding: Signal lines must use cables with copper braided mesh shielding. The cable shielding layer should be connected extensively on the VT-HNC100 side through a connector metal shell or shielding pin, and crimped with a tensioning device. The shielding layer is only grounded at the controller end.

Wiring principle:

Try to arrange the signal line and load line separately as much as possible to avoid parallel wiring.

Signal lines should avoid passing through areas with strong magnetic fields.

Try to lay signal lines continuously. If intermediate wiring is required, terminal blocks with shielding strips must be used.

For multi axis versions of analog/digital interfaces, it is recommended to use pre assembled distribution cables (such as material number R901189300/R901189302) with a maximum length of 2 meters.

External component power supply: When supplying power to external components such as encoders or pressure sensors, it is necessary to ensure that the input voltage of X1S meets the specifications of these components (such as 24V ± 5%, ripple<500mV).

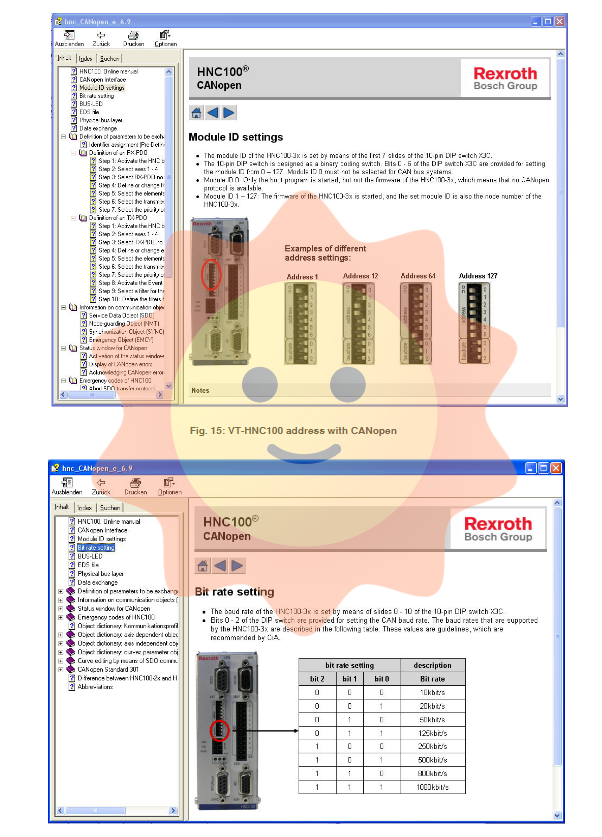

3. Bus address and network settings

Address switch: located on the front panel of the controller, used to set the node address of PROFIBUS DP or CANopen (1-127 binary settings). Position '0' is the boot mode used for data transmission.

PROFINET RT/EtherNet/IP: IP address via WIN-PED ® 7 software allocation, the front panel address switch is invalid in this mode.

PROFIBUS DP with TCP/IP: also via WIN-PED ® 7. Assign IP addresses to software.

Installation, debugging, and software configuration

1. Preparation before debugging

Essential tools: VT-HNC100... 3X controller, 24V power supply PC。

Essential software and connections:

WIN-PED ® 6 or 7 software: can be downloaded for free from the Bosch Rexroth official website.

Connection cable: RS232 interface cable (such as R900776897) or USB to RS232 converter (such as R901066684). For Ethernet models, TCP/IP network connections can also be used.

First power on inspection: Carefully check all wiring to ensure there are no errors before connecting 24V operating voltage. The controller needs to adapt to the ambient temperature for several hours to prevent condensation from forming inside the casing.

2. WIN-PED ® Software core functions

WIN-PED ® It is a dedicated PC software for VT-HNC100... 3X programming, setting, and diagnosis, providing the following core functions:

Machine Data Settings: A convenient dialog box for setting machine parameters online or offline.

NC Editor: Integrated syntax check and program compiler.

Parameter management: supports parameter definition and online value setting used in NC programs.

Process monitoring: Display the status of digital I/O and flag bits in multiple ways; Up to 16 process parameters can be recorded and graphically displayed.

Special function graphical definition: for example, defining functions through trajectories.

Bus Manager: Configure data exchange with higher-level control systems (PROFIBUS DP, PROFINET RT, or CANopen).

3. First debugging process

Physical connection: Connect the controller to the PC via RS232 cable or Ethernet cable.

Software startup: Install and start WIN-PED on PC ® And corresponding control type software.

Establish communication: in WIN-PED ® Select the correct port and protocol (such as COM port, TCP/IP address) from the "Communication" menu to establish an online connection with the controller.

Project creation and parameterization: Use software wizards or the "first step" guide to create a new project, configure controller parameters based on actual hydraulic axes and sensors, and define motion programs.

Initialization and Download: Compile and download (initialize) the complete project data (including parameters and programs) to VT-HNC100... 3X controllers.

Run test: After initialization is complete, the controller enters the "RUN" state, which can accept higher-level control instructions and execute pre programmed motion sequences.

The "First Steps" document provided on the official website is a quick guide to getting started with WIN-PED ® An excellent guide to software and completing initial debugging.

Operation, maintenance, and troubleshooting

1. Normal operation

During normal operation, users usually do not need to intervene. Even if a power failure occurs during operation, the controller can immediately return to a ready state after being powered on again, without the need for additional measures.

2. Cleaning and maintenance

Regularly clean the surface of the casing with a dry and dust-free soft cloth to prevent the accumulation of dirt and moisture.

It is strictly prohibited to use solvents or corrosive cleaning agents.

At least once a year, check the firmness and integrity of all plug-in and crimping connections, and inspect the cables for any damage or compression.

Keep the environment around the device clean and comply with IP20 protection requirements.

3. Maintenance and replacement

VT-HNC100... 3X can only be replaced as a whole unit and users are not allowed to disassemble and repair it themselves.

All repair work must be carried out by authorized service departments of Bosch Rexroth.

The repaired equipment needs to be sent in its original packaging to the designated service address (such as the main factory in Lor, Germany). The repaired device will revert to factory default settings, and users will need to re import all specific parameters and programs.

4. Troubleshooting steps

Systematic troubleshooting: Avoid blindly disassembling or adjusting parameters. Firstly, understand the working principle of the product in the entire system.

History and Change Investigation: Confirm whether the system or product has undergone any changes, repairs, or unexpected use before the malfunction occurred.

Utilizing diagnostic tools: fully utilizing WIN-PED ® The built-in diagnostic function of the software monitors I/O status, parameter records, and error messages online. Diagnosis and fault information can also be read through fieldbus.

5. Scrapping and environmental treatment

Products and packaging materials should be disposed of in accordance with the current regulations of the country where they are located. The product is mainly composed of electronic components and assemblies, and does not contain hazardous materials that may be released during use. Due to the high metal content, most of the products are recyclable. If it contains batteries or accumulators, they should be removed and sent to a dedicated battery recycling channel before recycling. Bosch Rexroth also provides product recycling services.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA