REXROTH WE 6X series directional valve

REXROTH WE6X series electromagnetic directional valve: in-depth technical analysis and application guide

Product Overview and Core Features

The WE6X series is a high-performance, direct drive electromagnetic directional valve launched by Bosch Rexroth, belonging to the 6-speed, 6X component series. This series of valves, with their compact design, reliable performance, and high power density, have become the core components for starting, stopping, and directional control of actuating elements (such as hydraulic cylinders and motors) in industrial hydraulic systems.

Its notable core features include:

High performance wet electromagnetic coil: Designed with wet pins, the electromagnetic coil is detachable and can rotate 90 degrees. When replacing the coil, there is no need to open the pressure sealing chamber, greatly simplifying maintenance work.

Standardized installation interface: The oil port layout of the valve complies with DIN 24340 Type A, ISO 4401-03-02-05, and NFPA T3.5.1 R2-2002 D03 standards, ensuring compatibility with commonly used valve plates (baseplates) in the market. The corresponding information on the base plate can be found in the data manual RE 45052.

Flexible electrical connections: Supports individual or central plug electrical connections to meet the wiring needs of different cabinets.

Optional rich features: Provides manual override, variants for smooth switching (see RE 23183), and inductive travel switches or proximity sensors for spool position detection (see RE 24830).

Core performance parameters:

Maximum working pressure: A, B, P ports can reach 350 bar (approximately 5076 psi).

Maximum traffic:

Direct current (DC) electromagnet: 80 L/min (approximately 21 US gpm).

AC electromagnetic coil: 60 L/min (approximately 15.8 US gpm).

The maximum pressure at T port is 210 bar for DC valve and 160 bar for AC valve. For type A and type B valve cores, the T port must be used as a leakage port.

Interpretation of Model Code and Valve Core Function

The first step in correctly selecting a product is to understand its ordering code. A complete WE6X valve code, such as "WE 6 6X E G24 N", includes all information about the valve series, diameter, serial number, spool function, electrical characteristics, and additional options.

Analysis of key code snippets:

Valve core function (4th and 5th digit codes): This is the core of selecting valve function. The WE6X series offers an extremely diverse range of valve core types to achieve different oil circuit control logics:

Three position four-way valve: such as E-type (middle A and B ports locked, P and T ports connected), C-type (middle all ports fully closed), Y-shaped (middle A and B ports locked, P port closed, T port connected to A and B), H-type (middle all ports interconnected), etc.

Two position four-way valve: such as Type A (single solenoid, spring reset), Type B (single solenoid, spring offset), etc.

Special function: For example, the R-type valve provides a return throttle function from the actuator to the oil tank at a specific position; Some valve cores (such as E1 type) have pre openings from P to A/B, and attention should be paid to the pressure enhancement effect that may occur in single piston rod cylinder applications.

Reset mode (6th code): No code indicates spring reset; '0' indicates no spring reset (requires dual electromagnets to maintain); '0F' indicates a springless reset with mechanical positioning (pulse type valve core).

Electromagnetic type (7th digit code): "E" represents high-performance wet pin electromagnet.

Voltage (8th and 9th digit codes): For example, "G24" is 24V DC, "W230" is 230V 50/60Hz AC, and "W110" is suitable for 110V/120V 50/60Hz AC. DC electromagnets can also be equipped with rectifiers (such as W110R) for use in AC power grids.

Manual operator (10th code): No code means no code is included; 'N' indicates a manual operator with an exposed part; N9 "indicates a hidden manual operator (standard configuration).

Working principle and structural characteristics

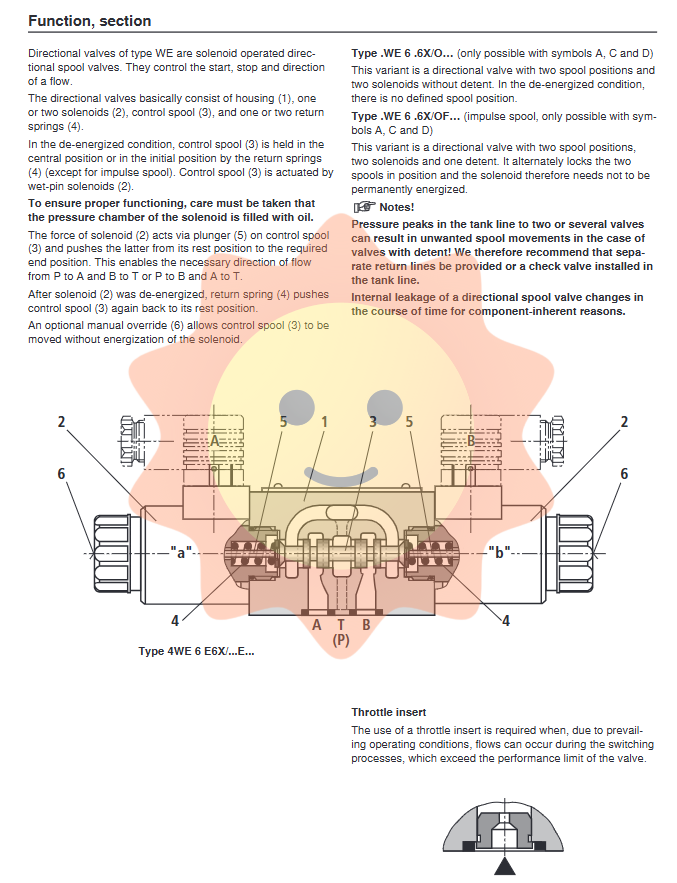

WE type directional valve is a slide valve operated by an electromagnet. Its basic components include a valve body (1), one or two wet electromagnets (2), a control valve core (3), and one or two reset springs (4).

In the power-off state, the reset spring (4) keeps the control valve core (3) in the neutral or initial position (except for pulse type valve cores). When the electromagnet (2) is energized, the force generated by it acts on the control valve core (3) through the push rod (5), pushing the valve core to overcome the spring force and move to the desired terminal position, thereby establishing a P → A, B → T or P → B, A → T oil circuit connection. After power failure, the spring force resets the valve core. The optional manual operator (6) allows the valve core to be moved without power, for debugging or emergency operation.

Important precautions:

Oil filling: To ensure the normal operation of the electromagnet, it is necessary to ensure that the pressure chamber of the electromagnet is filled with oil.

Application of positioning valve: For valves with mechanical positioning (0F type, pulse valve core), if multiple valves share the same return oil pipeline, the pressure peak in the return oil pipeline may cause the valve core to move unexpectedly. Therefore, it is recommended to provide independent return pipes for each valve or install one-way valves in the return pipes.

Internal leakage: Due to the inherent wear characteristics of the components, the internal leakage of the directional valve will change over time.

Key technical data and work limitations

1. Hydraulic and medium requirements

Hydraulic oil: It is recommended to use mineral oil (HL, HLP) that meets the DIN 51524 standard. It is also applicable to rapidly biodegradable hydraulic fluids that comply with VDMA 24568, such as HETG (rapeseed oil), HEPG (polyethylene glycol), and HEES (synthetic esters). When using HETG, HEPG, and HEES, attention should be paid to seal compatibility (usually FKM sealing is required).

Oil cleanliness: The system oil cleanliness must reach ISO 4406 level 20/18/15. Maintaining efficient filtration is key to preventing malfunctions and extending component lifespan.

Viscosity range: The working viscosity range is 2.8 to 500 mm ²/s.

Temperature range: The oil temperature range is usually -30 ° C to+80 ° C (NBR seal) or -15 ° C to+80 ° C (FKM seal).

2. Electrical characteristics and safety

Voltage tolerance: ± 10% of rated voltage.

Power consumption: approximately 30W.

Work schedule: 100% continuous work schedule (ED%).

Switching frequency: up to 15000 times/hour.

Coil surface temperature: The maximum allowable temperature is 120 ° C. The document specifically warns that for AC electromagnets, in the event of a malfunction (such as a stuck valve core), the coil surface temperature may sharply rise to over 180 ° C. Therefore, system design must consider the flash point of the working medium used (which needs to be at least 15K higher than the highest coil surface temperature) and assess potential hazards.

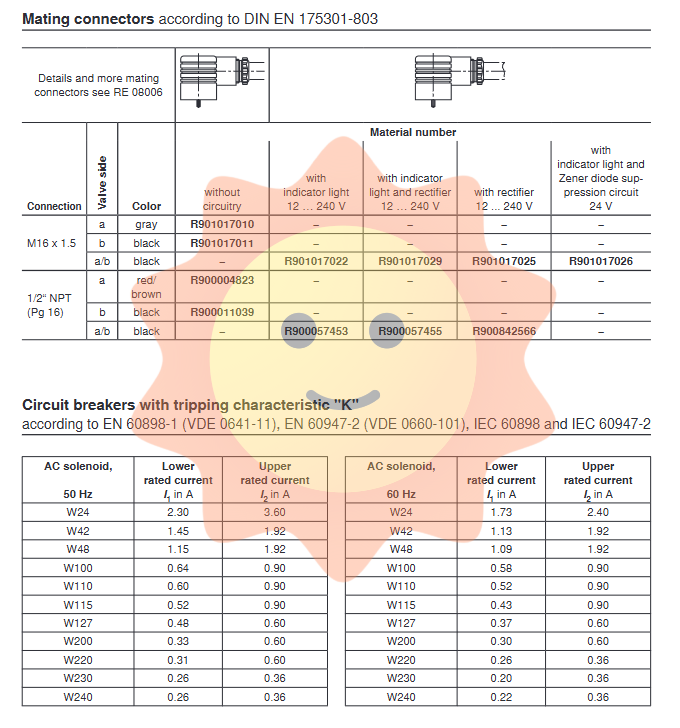

Fuse protection: Unless the ignition hazard can be eliminated in other ways, a circuit breaker with "K" type trip characteristics must be used for protection. The tripping current value should be 8-10 times the rated power consumption current (for 0.6 seconds), and the specific selection should refer to the lower limit current (I1) and upper limit current (I2) tables provided in the document.

3. Performance curve and commutation capability

The document provides a detailed performance curve chart (based on HLP46, oil temperature 40 ° C ± 5 ° C) to determine the passable flow rate of the valve at different pressure differentials (Δ p).

A crucial concept is the 'Switching Performance Limit'. This limit defines the maximum flow rate at which a valve can reliably complete a directional action under given pressure conditions. Attention must be paid to:

The maximum reversing capability values given in the chart are determined for the operating conditions of dual oil flow simultaneously (e.g. P → A and B → T).

If the actual working condition is a single oil flow (such as P → A, while port B is closed), the allowable reversing ability limit may be significantly reduced due to the different distribution of hydraulic forces acting on the valve core. In such applications, it is essential to consult the manufacturer.

The commutation capability test is conducted under the conditions that the electromagnet is at operating temperature, the voltage is 90% of the nominal value (undervoltage 10%), and there is no back pressure (preload) at the T port.

Installation, dimensions, and accessories

1. Mechanical installation

Installation location: Any.

Valve installation surface: It is necessary to ensure the specified surface roughness and flatness to ensure sealing.

Installation screws: The document strictly specifies the screw model, specifications, and tightening torque used to secure the valve to the base plate. According to different clamping lengths (42mm or 22mm), metric (ISO 4762-M5) and American (UNC 10-24 UNC) screw options and corresponding Bosch Rexroth material numbers are provided. The specified torque must be used to tighten to prevent leakage or damage to the valve body.

Oil port sealing: Use the same sealing ring for ports A, B, P, and T. The function definition of the oil port is clear, and it is strictly prohibited to exchange or block it at will.

2. Electrical connection and protection

Protection level: When using "K4" or "K7xL" series plugs and installing the docking plug, it can reach IP65; Using a "C4" plug can achieve IP66 rating; The use of the "K40" plug can achieve IP69K.

Terminal allocation (when connected centrally):

Single electromagnet: always connect terminals 1 and 2.

Double electromagnet: electromagnet "a" is connected to terminals 1 and 2, and electromagnet "b" is connected to terminals 3 and 4.

The protective grounding wire (PE) must always be correctly connected to the PE terminal.

3. Recommended attachments

Base plate: Choose according to the thread specifications of the oil port (G1/4, G3/8, G1/2 or SAE-6, -8, -10) and whether it has a locating pin hole.

Docking plug: The document provides material numbers for multiple plug options, including models without circuits, with indicator lights, with rectifiers, or with Zener diode suppression circuits.

Cable connector: such as Pg 16 or 1/2 "NPT cable gland.

Special tool: To avoid damage when operating the manual operator, it is recommended to use the special tool (material number R900024943).

Special variations and precautions

WE 6 6X/0... type: two position valve, dual solenoid, no positioning. The position of the valve core is undefined during power outage.

WE 6 6X/0F... type (pulse valve core): two position valve, dual electromagnet, with mechanical positioning. The valve core is alternately locked in two positions, and the electromagnet does not need to be continuously energized.

Throttle plug-in: When the flow rate that may occur during the switching process exceeds the limit of the valve's reversing ability, a throttle plug-in must be used to limit the flow rate and ensure reliable reversing.

Operation taboos:

It is strictly prohibited to operate two electromagnets simultaneously.

When using a manual operator, the fuel tank pressure should be below approximately 50 bar. When the manual operator is pressed down, it must be ensured that the electromagnet cannot be powered on for operation.

Summary of Selection and Maintenance Points

Clear requirements: Firstly, determine the required valve core function (median characteristics, number of digits), reset method, and whether manual operation is required based on the principle of hydraulic circuit.

Calculate flow rate and pressure: Based on the maximum flow rate and working pressure of the system, compare the performance curve and directional limit diagram to verify the flow capacity and directional reliability of the selected valve, paying special attention to single oil circuit conditions.

Select electrical specifications: Choose DC or AC voltage levels based on the on-site power supply situation. Consider the protection level and connection method (independent or centralized plug).

Check attachments: Select the correct base plate, installation screws, docking plugs, and seals based on the installation interface.

Comply with safety regulations: Install strictly according to the prescribed torque, ensure electrical grounding, and configure correct fuse protection as needed.

Maintenance: Regularly check the tightness and sealing of connections. When replacing the coil, ensure that the electromagnetic chamber is filled with oil. The valve itself is not repairable, and if there is an internal malfunction, it needs to be replaced as a whole.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA