REXRTOH ECODRIVE DKC Series Drive Controller Comprehensive Fault Diagnosis and Maintenance Guide

C700- Basic Load: Used to load preset control loop parameters (current loop, speed loop, etc.) that match the motor model from the motor feedback memory. Commonly used after replacing the motor.

D900 Series - Automatic Control Loop Adjustment: Command D9 to initiate the process of automatically optimizing the gain of the speed loop and position loop. This process will cause the axis to move automatically, so it is necessary to ensure that the enable signal is effective and that safety measures are in place within the range of motion. Subcodes D901-D906 indicate specific issues during the optimization process, such as inertia identification failure (D903), gain adjustment failure (D904), etc., which typically require adjusting relevant parameters or checking mechanical conditions.

Regulations for Safe Replacement of Driver Components

Directly replacing suspected faulty components is an effective means to quickly restore production. Chapter 6 of the document provides detailed steps for safely replacing the driver (DKC), motor, and cable.

Core security principles:

Complete power outage and discharge: Turn off the main switch and take measures to prevent accidental closing. Due to the back electromotive force generated by the rotation of the motor, it is necessary to wait for at least 1 minute for the internal capacitor to fully discharge before contacting the electrical connection parts.

Accurate model matching: Replacement parts must have the exact same model code as the original, which can be obtained from the component nameplate.

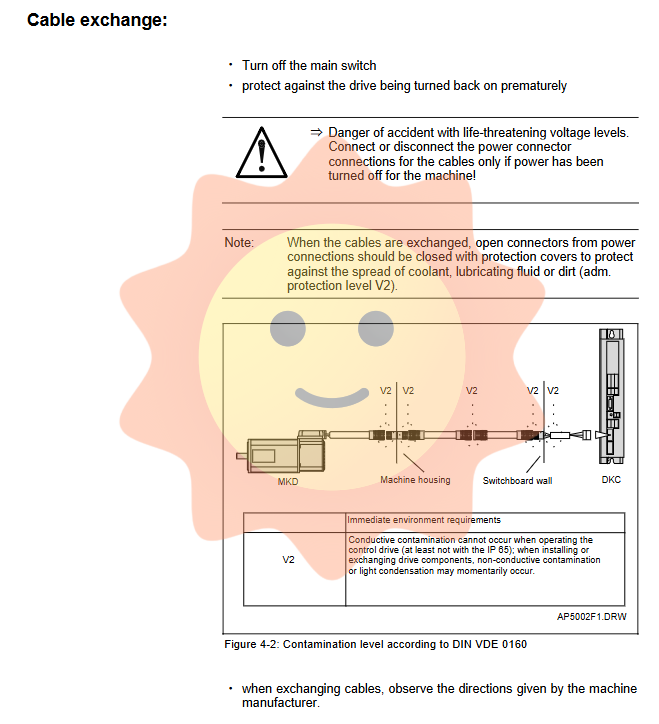

Anti pollution measures: When disassembling, the exposed joints should be immediately sealed with protective covers to prevent coolant, lubricating oil, or dust from entering (meeting the protection level requirements).

Key steps after replacement:

Replace Drive (DKC): After installing the new unit, it is necessary to correctly wire according to the drawing and use DriveTop to download the previously backed up machine parameter files to the new drive.

Replacing the motor: For systems that use built-in encoders as indirect position feedback, replacing the motor will result in absolute position loss. The absolute positional relationship between the axis and the machine coordinate system must be re established after the installation of the new motor.

Replace cable: Be sure to use cables that comply with the original factory connection diagram or machine manufacturer's specifications. Non original cables need to be carefully checked.

Collaboration with service system

The document concludes by providing INDRAMAT's customer service locations and contact information worldwide (Germany, Europe, and overseas). When encountering complex faults that cannot be solved, requiring spare parts support or deep repairs, professional personnel should be contacted in a timely manner. When returning the faulty component, attach a completed defect report (template provided in the document), detailing the fault phenomenon, environmental conditions, and steps taken, which will greatly help the service department to quickly diagnose and solve the problem.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA