REXRTOH IndraControl VDP series operation display

REXRTOH IndraControl VDP series operation display terminal: A complete guide to professional integration and application

In modern industrial automation systems, a reliable and intuitive human-machine interface (HMI) is the key to achieving efficient monitoring and operation. The IndraControl VDP series of operation display terminals launched by Bosch Rexroth has become the preferred choice for many mechanical equipment manufacturers due to its sturdy design, clear display, and flexible configuration. This article is based on the official technical document (R911336378_03), providing a comprehensive and in-depth professional analysis of the series of products, aiming to provide engineers and technicians with full process guidance from selection, installation to maintenance.

Product Overview and Target Positioning

The IndraControl VDP series belongs to passive operation and visualization terminals, which need to be used in conjunction with Bosch Rexroth control cabinet PC to form a complete PC based operation terminal solution. This document is mainly aimed at technical personnel of mechanical equipment manufacturers, guiding them to safely and correctly carry out mechanical and electrical installation and equipment debugging.

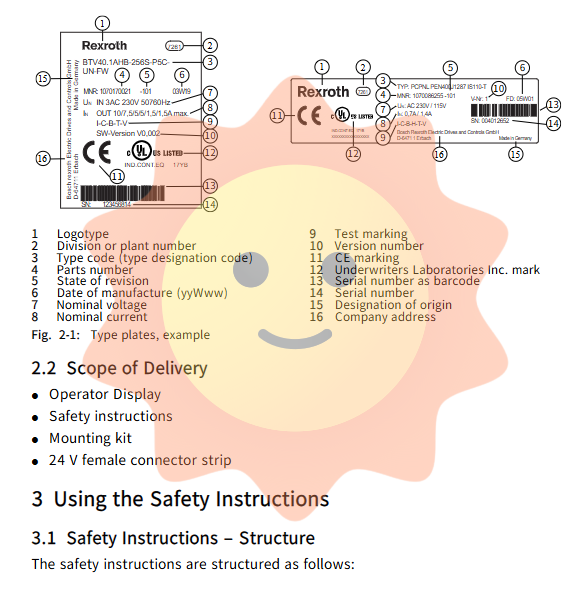

Product Scope: The document applies to all variants with model codes starting with "VDPxx. 3..." and not containing "... CG...". Users can confirm the model code on the device type nameplate (located on the back panel).

Core design concept: VDP terminals are designed for harsh industrial environments, with a front panel protection level of up to IP65 (compliant with DIN EN 60529), meeting NEMA Type 1 (UL) standards, effectively dustproof and waterproof, and adaptable to complex workshop environments.

2、 Detailed explanation of model series and technical specifications

The IndraControl VDP series mainly includes three screen size models to meet the display area and resolution requirements of different application scenarios.

IndraControl VDP 16.3

Display screen: 12.1-inch TFT LCD screen with a resolution of 800 x 600 pixels, supporting 16.7 million colors.

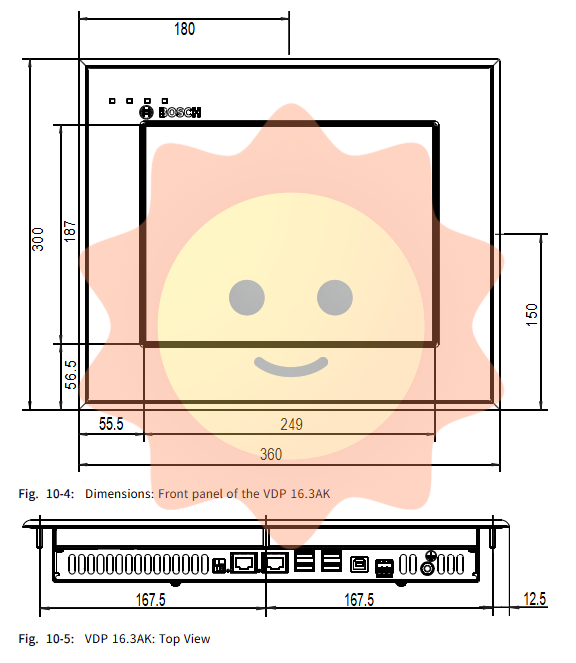

Variants: mainly include DB (standard light gray, with front USB), AK (customized graphite gray, without front USB), BK (standard light gray, with front USB), etc. The front panel size of AK version is slightly larger (360mm x 300mm), while the standard version is 350mm x 290mm.

Power consumption: rated voltage DC 24V, current consumption of about 0.85A, power consumption of about 20W.

Weight: Approximately 4.0 kg.

IndraControl VDP 40.3

Display screen: 15 inch TFT LCD screen with increased resolution to 1024 x 768 pixels and 16.7 million colors.

Variants: More diverse, including DE (touch screen), BI (buttons), DF (touch screen+buttons), DG, DI (touch screen+switch components), and AL (customized graphite gray, no front USB), etc. The standard version has a front panel size of 407mm x 370mm, while the AL version has a size of 417mm x 380mm.

Power consumption: The current consumption is about 1.05A, and the power consumption is about 25W.

Weight: Approximately 5.8 kg.

IndraControl VDP 60.3

Display screen: 19 inch TFT LCD screen, providing high resolution of 1280 x 1024, with the maximum amount of information displayed.

Operation: Mainly for touch screen operation (FE model).

Size: The front panel size is 483mm x 400mm.

Power consumption: The current consumption is about 1.7A, and the power consumption is about 40W, which is the highest in the series.

Weight: Approximately 7.3 kg.

Common technical features:

Voltage supply: The entire series is powered by DC 24V Safe Extra Low Voltage (SELV), and it is recommended to use industrial power supplies that comply with DIN EN 60742 standards, such as the Bosch Rexroth VAP01.1H series (part number R911171065).

USB interface: The back connection board of the device usually provides 4 USB Type-A host interfaces (XUSB1/2, XUSB3/4), and some models are also equipped with USB interfaces with IP65 protective covers on the front panel. Important limitation: The maximum output current of each USB port is 500mA, and the total current of all USB ports must not exceed 1A, otherwise it may cause the device power protection to be turned off.

Installation method: The installation depth for all models is 41mm, using a front panel installation method. Eight M4 mounting bolts are inserted into the opening from the front of the equipment and fixed with nuts at the back.

Core Interface and Connection Specification

Correct electrical connections are the cornerstone of stable equipment operation. The VDP terminal back connection board integrates all necessary interfaces.

Power interface (X1S1):

Type: 3-pin MC1.5/3-G-3.5 THT connector.

Pin definition: 1 pin (+24V), 2 pins (0V), 3 pins (empty). Copper wires must be used for connection.

Important notice: If the distance between VDP and control cabinet PC exceeds 50 meters and a non isolated power supply is used, balanced current may be generated due to pin 2 being internally connected to the casing. At this time, an isolated power supply must be used.

CDI interface (communication and display interface):

This is the core data and video channel between VDP and control cabinet PC, consisting of two RJ45 interfaces:

XSER (Data Interface): Color coded in purple, transmitting control data, keyboard signals, etc.

XVID (Video Interface): Color coded in black, transmitting display signals.

Connecting cables: Pre made cables specified by Bosch Rexroth (part numbers starting with R91117) must be used, with lengths ranging from 0.5 meters to 50 meters. Using non specified cables may cause signal interference or functional failure.

Relationship between cable length and resolution:

800 x 600 pixels: up to 80 meters in length.

1024 x 768 pixels: up to 70 meters in length.

1280 x 1024 pixels (VDP 60.3 only): up to 60 meters in length.

Expansion plan: When a longer distance is required, a Y-shaped repeater (VAC 01.1, part number R911171187) can be used for relay, which can cascade up to four operation display terminals.

DIP switch (S1):

S1/2 switch: used to adapt to long-distance cables. When the CDI cable length connected to the control cabinet PC is ≤ 30 meters, set it to OFF; When the length is greater than 30 meters, set it to ON. This setting affects the working speed of the USB interface.

Functional Area (FE) Connection:

Critical: It is necessary to ensure the reliable connection of the functional ground (M5 screw terminal) between the VDP terminal and the control cabinet PC. Otherwise, when only one side of the device's power supply is interrupted and restored, electronic devices may be damaged due to potential differences. The optimal approach is to connect the two functionally directly.

Mechanical installation and environmental requirements

Installation steps:

Process and install holes (with a diameter of 5mm) on the installation panel according to the drawing.

Remove the protective paper from the back sealing strip of the front panel.

Insert the terminal into the opening from the front, allowing the mounting bolt to pass through the hole.

Tighten the M4 nut with a torque of 1.4 Nm from the back of the panel to avoid mechanical damage.

Installation environment:

Space: At least 50mm of space should be reserved around the equipment for heat dissipation and cable layout.

Direction: Only vertical installation is allowed, with a maximum deviation of ± 45 degrees from the vertical direction.

Wiring: Cables should reserve loops and use stress relief devices. CDI cables must be kept away from strong interference sources such as motor cables, as parallel wiring can cause signal interference.

Environmental conditions:

Operating temperature:+5 ° C to+45 ° C.

Storage/transportation temperature: -20 ° C to+60 ° C.

Humidity: During operation and storage, the relative humidity should be between 5% and 85%, and condensation is not allowed.

Vibration and Shock: Compliant with EN 60068-2-6 (Vibration) and EN 60068-2-27 (Shock) standards, suitable for industrial environments.

Operating elements and device description

Membrane keyboard:

The device comes pre installed with an English keyboard driver, which supports language independent operations and does not require changing the driver for different language interfaces.

Function keys (F2-F9) and operation keys (OP2-OP9): Their functions are defined by the upper layer application software.

Machine function keys (M keys): L1-L8 and R1-R8 keys located on the left and right sides of the screen. Its status can be read in two ways: as a USB keyboard signal transmitted to the PC; or as a bit encoded form transmitted to the control cabinet PC through a serial connection of CDI interface, and can be further output through Profibus DP card insertion.

Status and error display LED:

The front panel provides system status indicator lights, such as:

HDD (yellow): Flashing indicates hard disk access; Continuous flashing may indicate SMART error.

Temp (red): Constant light indicates equipment temperature>50 ° C; flashing indicates control cabinet fan failure.

UPS (red): It lights up to indicate that the control cabinet PC is using UPS power supply and the main power supply has failed.

Note: Not all LEDs are activated on all control cabinet PCs, please refer to the PC documentation for details.

Safety, Maintenance, and Compliance

Security Warning:

The document adopts the security identifier of ANSI Z535.6 standard:

Danger: Failure to comply may result in death or serious injury.

Warning: Failure to comply may result in death or serious injury.

Caution: Failure to comply may result in minor injuries.

Tip: Failure to comply may result in property damage.

Touch screen operation: Only finger or dedicated stylus (part number 1070923266) operation is allowed, using sharp objects may damage the screen.

maintain:

Backlight: As a vulnerable component, the lifespan of the backlight is approximately 50000 hours (at an ambient temperature of 25 ° C). After the end of its lifespan, the brightness drops to 50% of its initial value. You can set the backlight off delay through the Windows' Power Options' to extend its lifespan.

Cleaning: Do not use solvents or high-pressure cleaning equipment. Only use a soft damp cloth to wipe.

Regular inspection: Check the tightness of all plug and terminal connections and the integrity of cables at least once a year.

Tightening torque: After maintenance, re tighten the screws using the specified torque (e.g. M3: 0.7 Nm, M4: 1.4 Nm).

Compliance:

CE Mark: Compliant with EMC Directive 2004/108/EC and related standards (such as EN 61000-6-2/4), suitable for industrial environments. After any equipment modification, CE compliance must be re verified.

UL/CSA certification: Complies with UL508 and CSA C22.2 No.142 standards (file number E210730). Similarly, modifications may result in certification invalidation and require revalidation.

Typical Applications and Support

The IndraControl VDP series is widely used in:

Handling and assembly system

Packaging and food processing machinery

Printing and papermaking machinery

machine tool

Wood processing machinery

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA