REXRTOH IndraDrive HMV01 series power supply unit

Its input characteristics and control voltage are similar to those of the. 1E series.

Output current: from 24A (W0018) to 160A (W0120).

Heat dissipation: It is worth noting that the HMV01.1R-W0120 model may require an external HAB01 fan unit (see Figure 2-5) to ensure sufficient heat dissipation, which requires space to be reserved during installation planning.

Power loss: The power loss during continuous operation of this series is significant, for example, the W0120 model can reach up to 2000W, which must be considered when designing the cooling system of the control cabinet.

3. General rated conditions

Environmental temperature: can operate according to rated data when ≤ 40 ° C; Reduced rating is required for use between 40 ° C and 55 ° C.

Pollution level: Level 2 (usually referring to only non-conductive pollution).

Wiring requirements: Copper wires with insulation level of 60/75 ° C and Class 1 are required for on-site wiring. The internal wiring specifications must comply with NFPA 79 and UL 508A standards, such as HMV01.1E-W0120 which requires the use of 4/0 AWG thick cables.

Installation, Connection, and Usage Guide

1. Power supply and input voltage

The HMS/HMD inverter must be used in conjunction with a listed DC power supply unit (such as HMV), and the power supply unit must be able to provide the rated input current required by the inverter. Branch circuit protection (fuses or circuit breakers) must be configured externally strictly according to the maximum values specified in the power unit manual.

2. Connection diagram

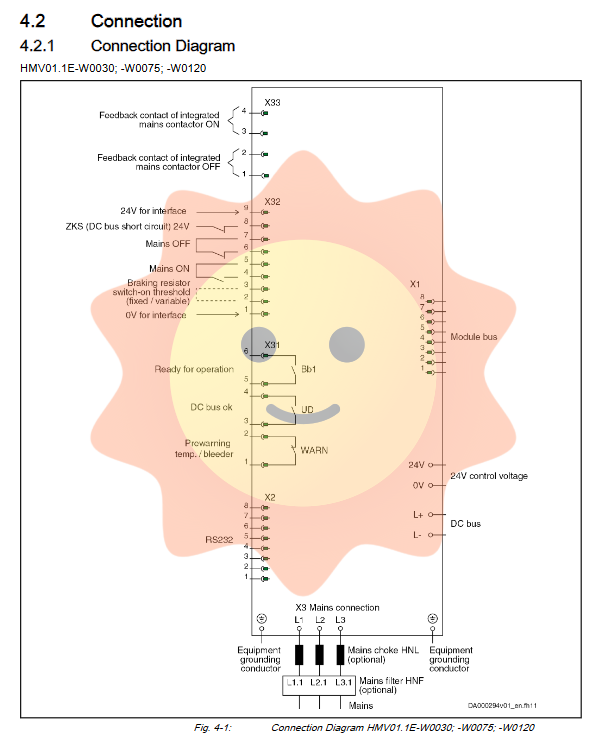

The document provides clear connection diagrams:

Figure 4-1 shows the connections of the HMV01.1E series (W0030/W0075/W0120), including main power inputs (L1, L2, L3, PE), DC bus outputs (L+, L -), 24V control power supply (X9), and internal relay contacts (X14).

Figures 4-2 and 4-3 show the connection methods of the HMV01.1R series (W0018/W0045/W0065) and (W0120), respectively. The W0120 model has a higher power output, and the specifications of the DC bus output terminal (X3) have also been correspondingly increased.

3. Detailed explanation of connection points (Table 4-2)

Main power supply and DC output (X3): bolted terminals are used. For example, for high-power models (Class B), using M10 bolts, a maximum of 120 mm ² single core or 70 mm ² double core cable can be connected, with a tightening torque of up to 20 Nm.

Control power supply (X9): using spring terminals, with a maximum connection cross-sectional area of 16 mm ² (6 AWG).

Internal relay contact (X14): can be used to provide feedback on states such as "power ready", using spring terminals and connecting up to 2.5 mm ² (12 AWG) wires.

Other interfaces (X31-X34, X40): used for internal system communication and 24V/0V reference potential distribution, often using push in or bolted terminals.

Supporting motor

As a power supply for the drive system, HMV01 needs to be matched with IndraDrive series servo motors for use. Chapter 3 of the document provides an overview of the project planning manual for the relevant motors, covering:

Asynchronous motor (MAD/MAF)

Synchronous servo motors (MSK, MKE, MS2N, MS2E for explosion-proof)

Torque Motor (MBT)

Linear motor (MLF, MCL)

Main spindle motor (MBS-H)

Users can refer to the corresponding documents for complete system selection and design based on specific applications.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA