REXRTOH IndraDrive HMV01 series power supply unit

REXRTOH IndraDrive HMV01 Power Unit: Reliable Power Core for Industrial Servo Drive

Product positioning and safety guidelines

The Bosch Rexroth IndraDrive HMV01 series power supply unit is a DC bus power supply device designed specifically for high-performance servo drive systems, and is a key component of the IndraDrive system family. It converts three-phase AC power (380-480V) into stable DC power (DC 435-680V or DC 750V), providing power for downstream HMS/HMD inverter modules. It is widely used in industrial automation fields such as machine tools, packaging, printing, and robots that require high dynamic response and reliability.

Safety is the primary prerequisite. The operating voltage of this product far exceeds the safe extra low voltage (SELV) range, posing a risk of fatal electric shock. Therefore, all installation, operation, and maintenance work must be carried out by qualified personnel. Qualified personnel refer to professional technicians who are familiar with the installation, commissioning, operation, and related hazards of electrical drive systems, and have the qualifications to safely operate electrical circuits (including power-off, grounding, and hanging and locking), and have received first aid training.

Be sure to read all accompanying documents thoroughly before operation. If the device is resold or transferred, the safety manual must be provided in the official language of the country where it is used. Structural modifications to hardware or decompilation of software are strictly prohibited. Only accessories and spare parts approved by Rexroth are allowed to be used.

Detailed explanation of key safety regulations

1. Electrical Contact and Shell Protection

Power off operation: Before touching any component with a voltage higher than 50V, the power must be cut off and ensure that it cannot be reconnected. After a power outage, wait for at least 30 minutes to ensure that the internal capacitors are fully discharged, and then conduct a power test to confirm.

Grounding (protective grounding) requirements: This is of utmost importance for the safe operation of HMV01. The equipment must be permanently and reliably grounded through a grounding terminal before and during operation.

High leakage current warning: The leakage current of HMV01 is greater than 3.5 mA. This means that if the grounding is poor, the casing may carry dangerous voltage.

Minimum cross-sectional area of grounding wire: In order to safely discharge leakage current, the cross-sectional area of grounding wire must meet strict requirements (see Table 1-1). For example, when the cross-sectional area of the phase wire is 2.5 mm ² (14 AWG), if a single grounding wire is used, its minimum cross-sectional area needs to be 10 mm ² (8 AWG); As an alternative, it is allowed to use two grounding wires with a cross-sectional area of 2.5 mm ² each.

2. Battery safety

The device may contain batteries inside. The designated battery type must be used according to the product specifications, and it is prohibited to:

Heating or charging a depleted battery (with the risk of explosion and burns).

Put the battery into the fire or disassemble it.

Abandoned batteries are classified as hazardous waste (with explosion risks during transportation and disposal) and must be disposed of separately in accordance with national regulations. They must not be mixed with ordinary garbage.

3. Expected use and environment

The HMV01 power unit is designed specifically for mechanical equipment in industrial environments and complies with IEC 60204-1 and NFPA 79 standards. It belongs to Class C3 products (conducted and radiated disturbance limits) defined by the IEC 61800-3 standard and is suitable for industrial environments. This means:

Non residential: Not suitable for connecting to public low-voltage power grids that supply power to residential areas, otherwise additional electromagnetic interference suppression measures may be required.

System integration: In order to meet the C3 EMC requirements, appropriate interference suppression measures (such as power filters and shielding) must be taken in the drive system.

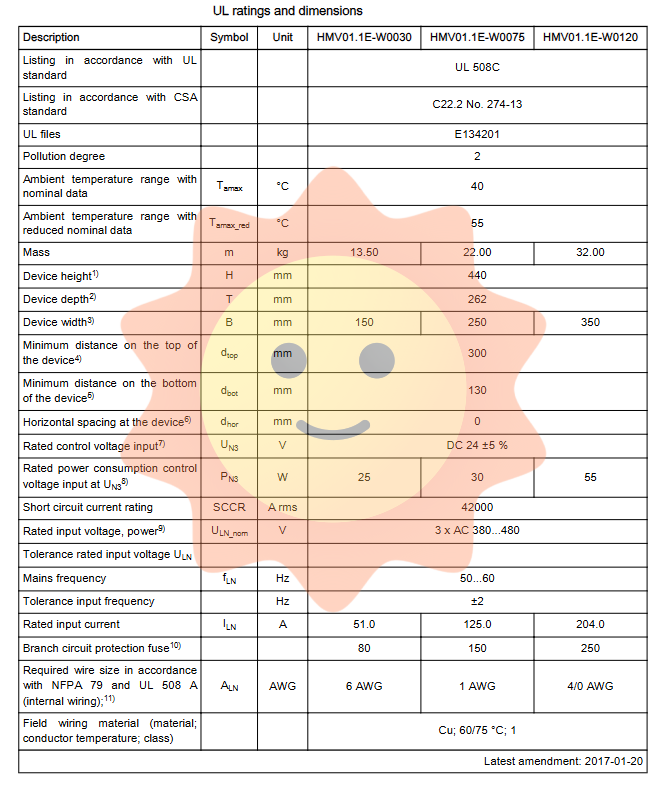

Technical specifications and model analysis

The HMV01 series is mainly divided into two sub series: HMV01.1E (standard DC bus voltage) and HMV01.1R (high DC bus voltage).

1. HMV01.1E series (output DC 435... 680V)

It includes three power models: - W0030, - W0075, and - W0120.

Input: 3-phase AC 380-480V, 50/60Hz.

Output current: from 69A (W0030) to 276A (W0120).

Control voltage: DC 24V ± 5%, supplying power to the internal control circuit.

Key dimensions: The height is uniformly 440mm, the depth is 262mm, and the width increases with power (150mm, 250mm, 350mm).

Installation spacing: At least 300mm of air duct should be left at the top, 130mm at the bottom, and can be installed side by side in the horizontal direction (with a spacing of 0mm).

Protection: Use UL listed J-class (600V AC) fuses for branch circuit protection, with rated values corresponding to 80A, 150A, and 250A. Its short-circuit current rating (SCCR) is as high as 42000 Aeff.

2. HMV01.1R series (output DC 750V)

It includes four models: - W0018, - W0045, - W0065, and - W0120.

Its input characteristics and control voltage are similar to those of the. 1E series.

Output current: from 24A (W0018) to 160A (W0120).

Heat dissipation: It is worth noting that the HMV01.1R-W0120 model may require an external HAB01 fan unit (see Figure 2-5) to ensure sufficient heat dissipation, which requires space to be reserved during installation planning.

Power loss: The power loss during continuous operation of this series is significant, for example, the W0120 model can reach up to 2000W, which must be considered when designing the cooling system of the control cabinet.

3. General rated conditions

Environmental temperature: can operate according to rated data when ≤ 40 ° C; Reduced rating is required for use between 40 ° C and 55 ° C.

Pollution level: Level 2 (usually referring to only non-conductive pollution).

Wiring requirements: Copper wires with insulation level of 60/75 ° C and Class 1 are required for on-site wiring. The internal wiring specifications must comply with NFPA 79 and UL 508A standards, such as HMV01.1E-W0120 which requires the use of 4/0 AWG thick cables.

Installation, Connection, and Usage Guide

1. Power supply and input voltage

The HMS/HMD inverter must be used in conjunction with a listed DC power supply unit (such as HMV), and the power supply unit must be able to provide the rated input current required by the inverter. Branch circuit protection (fuses or circuit breakers) must be configured externally strictly according to the maximum values specified in the power unit manual.

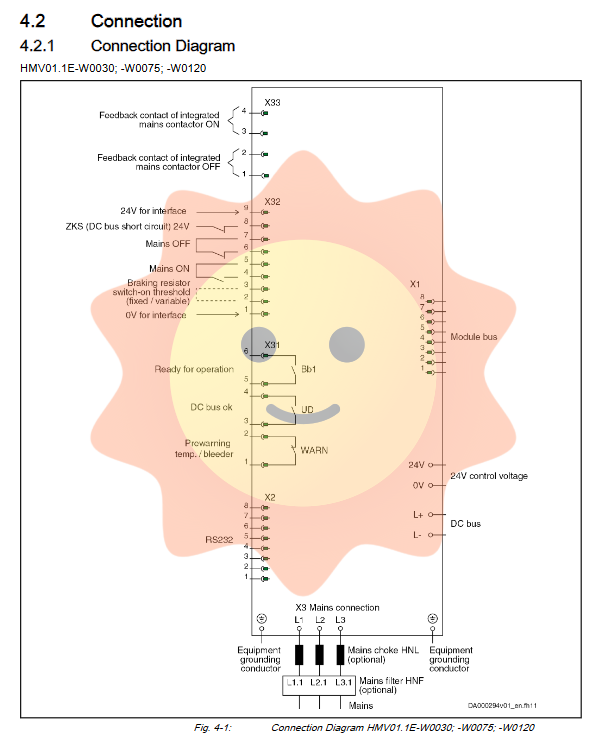

2. Connection diagram

The document provides clear connection diagrams:

Figure 4-1 shows the connections of the HMV01.1E series (W0030/W0075/W0120), including main power inputs (L1, L2, L3, PE), DC bus outputs (L+, L -), 24V control power supply (X9), and internal relay contacts (X14).

Figures 4-2 and 4-3 show the connection methods of the HMV01.1R series (W0018/W0045/W0065) and (W0120), respectively. The W0120 model has a higher power output, and the specifications of the DC bus output terminal (X3) have also been correspondingly increased.

3. Detailed explanation of connection points (Table 4-2)

Main power supply and DC output (X3): bolted terminals are used. For example, for high-power models (Class B), using M10 bolts, a maximum of 120 mm ² single core or 70 mm ² double core cable can be connected, with a tightening torque of up to 20 Nm.

Control power supply (X9): using spring terminals, with a maximum connection cross-sectional area of 16 mm ² (6 AWG).

Internal relay contact (X14): can be used to provide feedback on states such as "power ready", using spring terminals and connecting up to 2.5 mm ² (12 AWG) wires.

Other interfaces (X31-X34, X40): used for internal system communication and 24V/0V reference potential distribution, often using push in or bolted terminals.

Supporting motor

As a power supply for the drive system, HMV01 needs to be matched with IndraDrive series servo motors for use. Chapter 3 of the document provides an overview of the project planning manual for the relevant motors, covering:

Asynchronous motor (MAD/MAF)

Synchronous servo motors (MSK, MKE, MS2N, MS2E for explosion-proof)

Torque Motor (MBT)

Linear motor (MLF, MCL)

Main spindle motor (MBS-H)

Users can refer to the corresponding documents for complete system selection and design based on specific applications.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA