REXRTOH SE 200 Electric Tool Controller Details

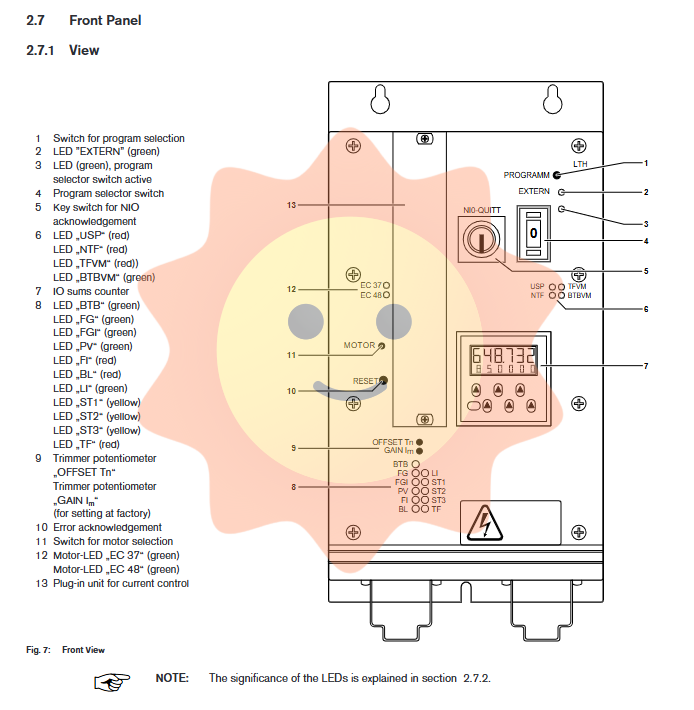

Multiple LED lights on the panel visually display the system status:

BTB (green): Power unit ready

TF (red): Temperature fault (power unit or motor)

FI (red): Current fault (short circuit)

EC 37/EC 48 (green): Selected motor type

ST1/ST2/ST3 (yellow): selected speed gear

Externaln (green): External program selection activation

2. Key setting switch

Motor selection switch (MOTOR): Set according to the connected EC motor type (EC 37 or EC 48). When connecting ECH/ECM series tools, it must be set to EC 48.

Program selection switch: Switch between "internal" and "external" program selection modes. In internal mode, select the program through the program selector switch on the panel; In external mode, select programs in hexadecimal code through user interface X13.

Program selector switch: used to select the tightening program (0-15) in internal mode. When cooperating with the current controller, even numbers correspond to program 0 (tightening), odd numbers correspond to program 1 (tightening), and program 15 corresponds to the loosening operation.

3. NIO (unqualified) confirmation and error reset

When the tightening process fails (NIO), the system will lock the subsequent startup until NIO confirmation is performed. The confirmation can be done through the front panel key switch or the NIO reset button on the tool. When a malfunction occurs, the green BTB light goes out and the "RESET" button needs to be pressed to reset the error (if the power module fails, the device needs to be restarted for reset).

4. Total IO counter

This mechanical counter records all qualified tightening operations (IO), with a maximum count of 999999. It has the following functions:

Counting mode: can be set to either Add or Sub mode.

Preset function: A target value can be preset, and after reaching it, an SIO signal can be output through interface X13.

Loop mode: After reaching the target value and outputting a signal, the counter automatically resets and restarts counting.

Battery powered: Equipped with two built-in 3.6V lithium batteries, ensuring data storage for 8 years after power failure. When the battery is low, it displays "Lo bat" and needs to be replaced by a professional.

Interface definition and system integration

The bottom of LTH integrates all electrical interfaces, which is the key to achieving system expansion and signal interaction.

1. Detailed explanation of core interfaces

X1 (power supply): Standard IEC socket, input main power supply.

X3 (Electric Tool): 19 pin+PE circular connector, providing motor power (U, V, W), encoder feedback (CH1, CH2, INDX), temperature signal (TM1E), start stop control (START), and 24V power supply.

X8 (SE 200 command line): 25 pin D-Sub male head, used for communication with SE 200 controller, transmitting enable (FGE), speed gear (ST1-3), status feedback (BTB1/2), torque measurement value (IM1/2), diagnosis and other signals.

X13 (User Interface): A 15 pin D-Sub male connector that provides the most commonly used external control signals, such as program selection (PRG1-4), IO/NIO result output, SIO counter output/reset, test run (TA), etc. It is the main interface for connecting PLCs or simple control devices.

2. Optional interface

X10 (current control): Used to connect ST1 and other current control cards to achieve independent tightening control.

X11 (Material Control): Used for extended material management functions, prohibited from use when operating handheld tools.

Ordering information and system matching

Bosch Rexroth offers a complete ecosystem of intelligent tools:

Electric tools: EC tools covering multiple torque and speed specifications such as ECH12/28/37/57 and ECM16.

Power supply units: LTH 230V and LTH 110V.

Controller and accessories: SE 200 controller, ST1 current control card, PM-1 programming module, KM-1 calibration module, and dedicated connecting cables (linear and spiral, length 1.6m to 10m optional).

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA