REXRTOH SE 200 Electric Tool Controller Details

REXRTOH SE 200 Electric Tool Controller: Core Technology Analysis of High Precision Tightening System

Product Overview and Safety Standards

The Bosch Rexroth SE 200 power tool controller is an intelligent control unit designed specifically for industrial screw tightening systems, typically used in conjunction with LTH series power units to achieve precise control of EC (electronic commutation) power tools. This system is suitable for high-precision tightening process scenarios such as automotive assembly, aerospace, and electronic manufacturing, and has advanced functions such as torque control, angle monitoring, process feedback, and data recording.

Before operating this equipment, safety regulations must be strictly followed. This technical document is aimed at technical personnel who have knowledge of electrical and automation safety and have undergone professional training. The equipment adopts a "protective isolation" design, which achieves electrical isolation between the power supply and the tool through an isolation transformer to prevent fault voltage from being transmitted to the operator. All devices connected to interfaces (X2, X7, X8, X10, X11) must comply with the "low voltage protection" standard. User interface X13 is optocoupler isolated to further ensure safety.

LTH power unit: system power core

1. Technical specifications

The LTH power unit has two voltage specifications: LTH 230V (suitable for 220-240V ± 10%, 50/60Hz) and LTH 110V (suitable for 100-110V ± 10%, 50/60Hz). The main technical parameters are as follows:

Protection level: IP 42

Protection category: Class I (protective grounding)

Output characteristics: Output voltage 0-230V, rated current 2A, maximum instantaneous current 12A, output frequency 0-500Hz

Working environment: temperature from 0 ° C to+50 ° C, humidity from 20% to 90%, no condensation

Physical dimensions: 310 mm x 160 mm x 310 mm (length x width x height), weight 13.4 kg

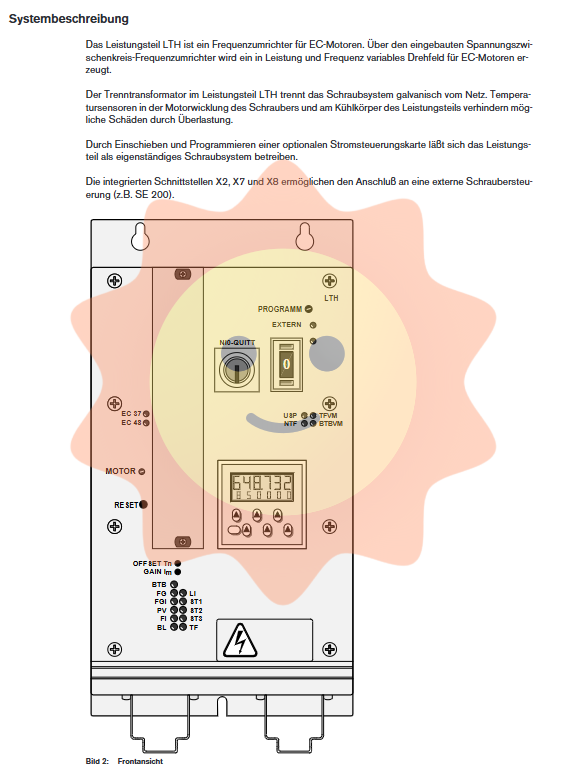

2. System description and hardware composition

LTH is essentially a frequency converter used for EC motors, which generates a three-phase rotating magnetic field with adjustable power and frequency through a built-in intermediate circuit frequency converter. Its core hardware includes:

Power input module: equipped with standard IEC socket (cold equipment plug), built-in 6.3A slow melting fuse.

Grid filter: Suppresses the radio interference voltage generated by the frequency converter.

Isolation Transformer: Compliant with VDE 0551, it achieves electrical isolation between power supply and system circuits and is a safety critical component.

Power module: Provides DC power to the output stage and supplies power to the logic circuit, optional current controller, and power tools through a switching power supply.

Output stage: composed of 6 IGBT transistors and 6 potential isolated driving circuits, with motor current measurement, short-circuit protection, and temperature monitoring functions.

Control module: responsible for regulating the current and speed of the EC motor, processing simulated set values from the current controller or external controller, and evaluating the dual channel incremental encoder signal of the motor.

Installation, Connection, and Startup

1. Mechanical installation

The LTH unit is installed through the rear wall lifting ring, and it is recommended to reserve at least 40mm of space around it to ensure air circulation. When installing multiple units in a centralized manner, it is necessary to avoid cable trays or wire harnesses blocking the air ducts. In environments with high dust or humidity, LTH must be installed in a control cabinet with a protection level of IP 54.

2. Electrical connection sequence and specifications

The following order must be followed when connecting:

Insert interface cables (X2, X7, X8, etc.) and secure them with screws.

Insert the Amphenol connector (X3) of the power tool and tighten the locking ring.

Insert the power cord with an IEC plug and secure it with a wire clamp.

Turn on the power switch at the bottom of the unit.

Critical safety warning:

It is strictly prohibited to connect equipotential bonding wires (PE) to electric tools, as the system adopts a "protective isolation" design.

Devices connected to interfaces X2, X7, X8, X10, and X11 must meet the requirement of "protecting low voltage".

Only tool components and cables specified or authorized by the manufacturer can be connected (see ordering section).

3. System configuration mode

LTH supports two main working modes:

Connect external controllers (such as SE 200): Communicate with SE 200 controllers through interfaces X2 (sensors), X7 (material control), X8 (command lines) to achieve complex tightening program management and monitoring.

Connect optional current controller (such as ST1): After inserting the current control card, LTH can operate as an independent tightening system, suitable for standardized tightening tasks.

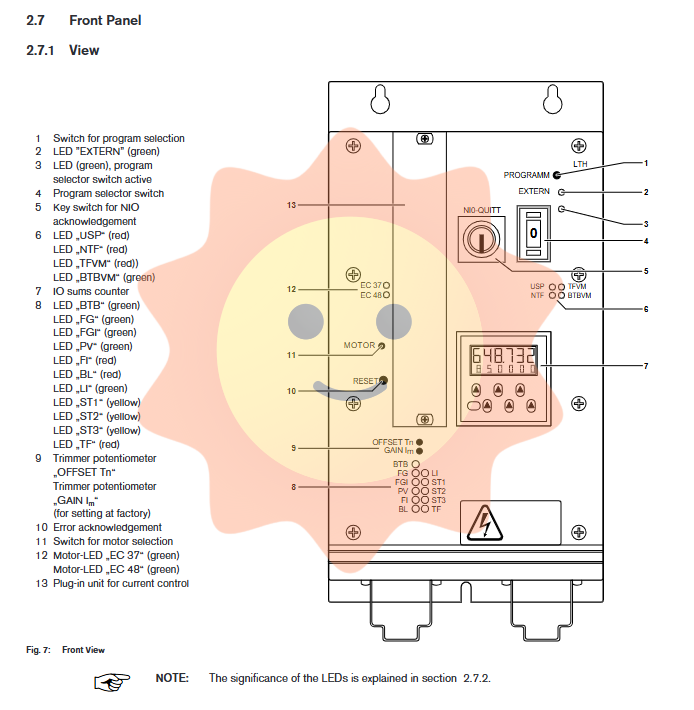

Operation interface and function settings

The front panel of LTH is the main human-machine interaction interface, including status indicator lights, setting switches, and counters.

1. LED status indication

Multiple LED lights on the panel visually display the system status:

BTB (green): Power unit ready

TF (red): Temperature fault (power unit or motor)

FI (red): Current fault (short circuit)

EC 37/EC 48 (green): Selected motor type

ST1/ST2/ST3 (yellow): selected speed gear

Externaln (green): External program selection activation

2. Key setting switch

Motor selection switch (MOTOR): Set according to the connected EC motor type (EC 37 or EC 48). When connecting ECH/ECM series tools, it must be set to EC 48.

Program selection switch: Switch between "internal" and "external" program selection modes. In internal mode, select the program through the program selector switch on the panel; In external mode, select programs in hexadecimal code through user interface X13.

Program selector switch: used to select the tightening program (0-15) in internal mode. When cooperating with the current controller, even numbers correspond to program 0 (tightening), odd numbers correspond to program 1 (tightening), and program 15 corresponds to the loosening operation.

3. NIO (unqualified) confirmation and error reset

When the tightening process fails (NIO), the system will lock the subsequent startup until NIO confirmation is performed. The confirmation can be done through the front panel key switch or the NIO reset button on the tool. When a malfunction occurs, the green BTB light goes out and the "RESET" button needs to be pressed to reset the error (if the power module fails, the device needs to be restarted for reset).

4. Total IO counter

This mechanical counter records all qualified tightening operations (IO), with a maximum count of 999999. It has the following functions:

Counting mode: can be set to either Add or Sub mode.

Preset function: A target value can be preset, and after reaching it, an SIO signal can be output through interface X13.

Loop mode: After reaching the target value and outputting a signal, the counter automatically resets and restarts counting.

Battery powered: Equipped with two built-in 3.6V lithium batteries, ensuring data storage for 8 years after power failure. When the battery is low, it displays "Lo bat" and needs to be replaced by a professional.

Interface definition and system integration

The bottom of LTH integrates all electrical interfaces, which is the key to achieving system expansion and signal interaction.

1. Detailed explanation of core interfaces

X1 (power supply): Standard IEC socket, input main power supply.

X3 (Electric Tool): 19 pin+PE circular connector, providing motor power (U, V, W), encoder feedback (CH1, CH2, INDX), temperature signal (TM1E), start stop control (START), and 24V power supply.

X8 (SE 200 command line): 25 pin D-Sub male head, used for communication with SE 200 controller, transmitting enable (FGE), speed gear (ST1-3), status feedback (BTB1/2), torque measurement value (IM1/2), diagnosis and other signals.

X13 (User Interface): A 15 pin D-Sub male connector that provides the most commonly used external control signals, such as program selection (PRG1-4), IO/NIO result output, SIO counter output/reset, test run (TA), etc. It is the main interface for connecting PLCs or simple control devices.

2. Optional interface

X10 (current control): Used to connect ST1 and other current control cards to achieve independent tightening control.

X11 (Material Control): Used for extended material management functions, prohibited from use when operating handheld tools.

Ordering information and system matching

Bosch Rexroth offers a complete ecosystem of intelligent tools:

Electric tools: EC tools covering multiple torque and speed specifications such as ECH12/28/37/57 and ECM16.

Power supply units: LTH 230V and LTH 110V.

Controller and accessories: SE 200 controller, ST1 current control card, PM-1 programming module, KM-1 calibration module, and dedicated connecting cables (linear and spiral, length 1.6m to 10m optional).

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA