Rockwell Automation MD60 AC Drive

MD60 AC Drive Comprehensive Guide: Installation, Configuration, and Troubleshooting

The MD60 AC drive is a high-performance frequency converter from Rockwell Automation (Reliance Electric), suitable for various industrial motor control applications. This guide is based on the MD60 user manual (version 3.0) and systematically introduces its safety instructions, installation requirements, parameter settings, communication configuration, and common fault handling methods. It aims to provide practical and comprehensive reference materials for electrical engineers, system integrators, and maintenance personnel.

Safety Notice and Precautions

Before operating the MD60 drive, the following safety regulations must be strictly followed to prevent personal injury or equipment damage:

Qualification requirements: Only professional electrical personnel familiar with the structure, operation, and related hazards of the equipment are allowed to install, debug, and maintain it.

High voltage capacitor discharge: The driver contains high voltage capacitors inside, and after power failure, it is necessary to wait for at least 3 minutes to ensure discharge to a safe voltage. The LED display turning off does not mean that the capacitor has been completely discharged.

Zero speed operation warning: The driver can operate at zero speed, and users must use protective devices, sound and light alarms, and other means to alert operators to avoid accidental injury.

Electrostatic protection: The driver contains components that are sensitive to static electricity, and anti-static measures must be taken during operation.

External emergency stop circuit: A hard wired emergency stop circuit independent of the driver circuit must be configured to ensure that the system can be immediately cut off in case of abnormal conditions.

Grounding and shielding: The safety grounding (PE) of the driver must be reliably connected to the system grounding. The shielding layer of the motor cable should be grounded at both ends of the driver and motor, while the shielding layer of the control signal cable should only be grounded at the source end.

Power and motor matching: Ensure that the input power of the driver matches the rated parameters of the motor to avoid equipment failures caused by voltage and frequency discrepancies.

Product identification and model description

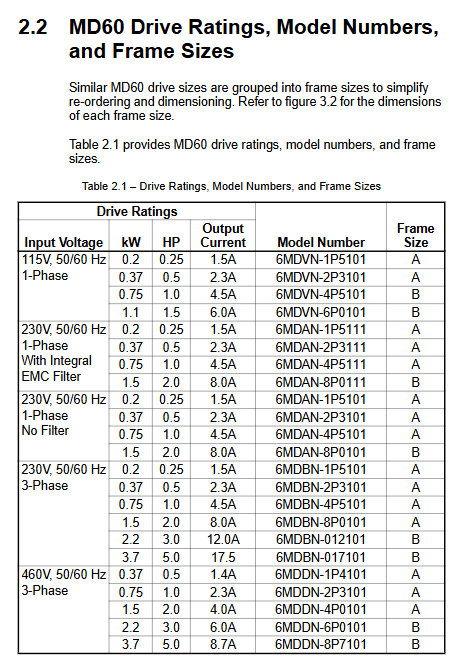

The MD60 driver can be identified by a model label, which includes information such as voltage level, power, phase, and whether a filter is included. For example:

6MDAN-1P5: 230V single-phase input, 0.2kW, including EMC filter.

6MDBN-012:460V three-phase input, 2.2kW.

Drivers are classified by rack size for easy selection and installation. When storing, avoid corrosive environments with a temperature range of -40 ° C to 85 ° C and a humidity of 0% to 95% without condensation.

Installation and wiring specifications

1. Installation environment requirements

Temperature and protection level:

IP20/Open: -10 ° C to 50 ° C

NEMA 1/IP30 (requires installation kit): -10 ° C to 40 ° C

Installation spacing: Adequate heat dissipation space should be maintained around the drive, and it is recommended that the top and side spacing be ≥ 100mm.

Installation method: 35mm DIN rail or M4 screws can be used for fixation, and the thickness of the installation panel should not be less than 1.9mm.

2. Power wiring

Input power check: Confirm that the power supply voltage matches the driver nameplate, especially paying attention to whether it is a grounding system. In non grounded systems, the MOV ground jumper (located at the bottom left of the power terminal block) needs to be removed.

Power filter: When single-phase drivers or external filters are used, the ground leakage current may be high, and it is necessary to ensure reliable grounding of the AC power system.

Cable selection: It is recommended to use 600V, 75 ° C or 90 ° C copper core cables, and Belden 295xx or Shawflex series shielded cables are recommended.

Protection device: The input terminal must be equipped with a fuse or circuit breaker, as specified in Table 5.4 of the manual.

3. Motor cables and reflected wave protection

Cable length: It is recommended to keep the motor cable as short as possible. Long cables should be equipped with output reactors to suppress reflected voltage.

Cable type: Shielded or unshielded cables can be selected. When multiple cables are parallel, it is recommended to use shielded cables to reduce interference.

4. Control wiring

Control cable: It is recommended to use twisted pair shielded cables, such as Belden 8760, with a minimum distance of 0.3m between the control signal line and the power line.

I/O terminal description:

Digital input: Supports source type (SRC) and drain type (SNK) modes, set through DIP switches.

Analog input: Supports 0~10V voltage input (100k Ω impedance) and 4~20mA current input (250 Ω impedance).

External emergency stop: A hard wired emergency stop circuit independent of the driver must be configured, in accordance with EN 60204-1 standard.

Parameter Setting and Programming

The MD60 driver parameters are divided into basic parameter group (P), advanced parameter group (A), and display parameter group (d), which can be set through integrated keyboard or RS485 communication.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands