Comprehensive analysis and detailed explanation of key technologies for SIEMENS SIMADYN D hardware system

2.4 Specialized Technical Modules

T400 technology module: integrates rich local I/O resources, including analog input/output, digital I/O, encoder interface, and serial communication port (RS232/485), which can be directly used for low-cost drive control or as an option board for SIMOVERT MASTERDRIVES. Its characteristics include:

2-channel incremental encoder interface (supporting HTL and RS422)

2-channel absolute encoder interface (SSI/EnDet)

2-channel serial interface (can be used for USS, Peer to Peer, or services)

Integrated Flash and DRAM, supporting independent operation or communication with the host

ITDC module: specifically designed for thyristor control of line commutation drivers (such as SITOR power units), integrating current regulators, trigger pulse generation, and monitoring functions.

Installation, Grounding, and EMC Key Guidelines

To ensure the reliable operation of the system in industrial electromagnetic environments, the manual provides detailed provisions for mechanical installation, grounding, cable laying, and shielding measures.

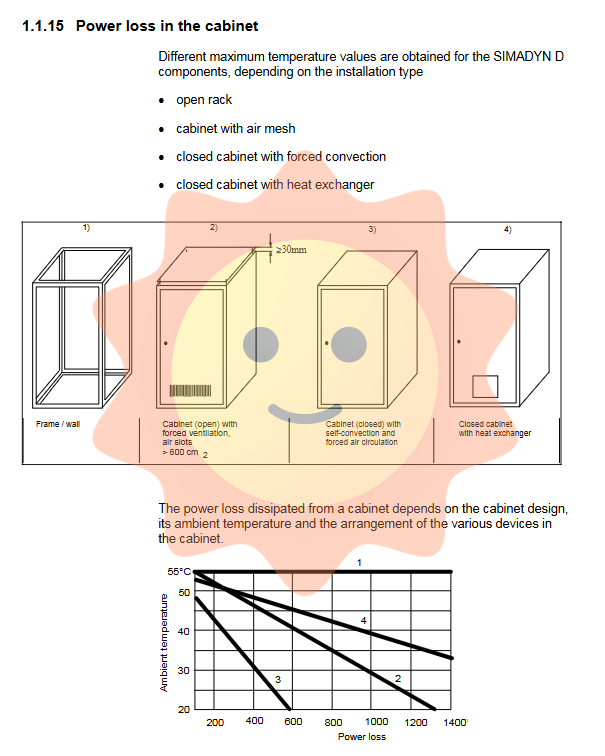

3.1 Cabinet and Installation Requirements

SIMADYN D must be installed in a metal cabinet, which should be fully enclosed and only accessible to authorized personnel.

Grounding/equipotential busbar (≥ 6mm ² copper cable) should be installed inside the cabinet, and all components (rack, power supply, external equipment) should be connected to this busbar nearby.

During module installation, screws must be tightened, and shielding cover plates must be installed on empty slots to ensure good electromagnetic sealing and heat dissipation.

3.2 Cable and Shielding Specifications

All signal cables must be shielded, with the shielding layer connected to the shielding busbar at the entrance of the cabinet and continuously shielded to the terminal module.

Analog signal cables are recommended to be grounded at one end (cabinet side), while digital and communication cable shielding layers should be grounded at both ends.

The distance between signal cables and power cables (>500V AC) should be at least 10cm, and the distance between high-voltage cables (>1kV AC) should be greater than 30cm.

Serial communication cables (such as PROFIBUS, USS) should use twisted pair shielded cables, and the connector housing must be grounded.

3.3 Power Supply and Filtering

The incoming line of the AC power supply should be equipped with a line filter (such as 250V AC/10A), installed near the entrance of the cabinet, and the grounding wire of the filter should be short and thick.

It is recommended to install filtering capacitors or filters on the 24V DC power supply to suppress conducted interference.

The rated current of the switching power supply needs to consider the starting current of SIMADYN D (up to 200% of the rated value).

3.4 ESD Protection

All modules contain components that are sensitive to static electricity, and static electricity must be released through a grounded wristband or touching grounded metal before contact.

Anti static packaging (such as metallized plastic bags, conductive foam) must be used for module storage and transportation.

When welding or measuring, tools and instruments must be grounded.

System Integration and Typical Applications

SIMADYN D, with its powerful real-time processing capabilities and flexible modular structure, is particularly suitable for the following application scenarios:

Multi motor drive system: Accurate control of DC/AC drives is achieved through ITDC or T400 modules, combined with CS12/CS22 fiber optic backplane coupling, to construct a multi rack high-speed synchronization system.

High performance motion control: utilizing PM6 CPU and IT41 expansion module to achieve multi axis linkage, position synchronization, and trajectory planning, suitable for fields such as CNC machine tools and robots.

Distributed process automation: Integrating remote I/O stations, sensors, and actuators through PROFIBUS-DP (SS5 module) or industrial Ethernet (CSH11 module) to build a workshop level control network.

Technical upgrade and transformation: The T400 module can be directly inserted into SIMOVERT MASTERDRIVES frequency converters to enhance their control functions and achieve low-cost upgrades of existing equipment.

Summary

The SIMADYN D system represents a high-end solution in the field of industrial drive and control, with its design fully considering real-time performance, reliability, and flexibility. From sturdy rack design, high-performance CPU, abundant I/O options to comprehensive communication support, this system is capable of handling the most demanding industrial environments and complex control tasks. Strict installation and EMC guidelines are not only compliance requirements, but also fundamental guarantees for the long-term stable operation of the system. For system integrators and end users, a deep understanding of their hardware architecture and technical details will help maximize the potential of the system and build efficient and reliable automation platforms.

With the development of Industry 4.0 and intelligent manufacturing, the demand for modular, networked, and real-time collaborative control systems is increasing. Although SIMADYN D is the previous generation product, its design concept and technical implementation still have significant reference value, and have laid a solid foundation for Siemens' advanced control systems based on platforms such as TDC and S7-400H in the future.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA