SIEMENS SIMOVERT MASTERDRIVES Vector Control Series

Functional Data Set (CDS): switchable online, used to change process parameters such as acceleration and amplitude limit.

Motor Data Set (MDS): It needs to switch between shutdown states to drive different motors or change motor control modes.

BICO dataset: switchable online, used to change the signal source for commands and set values.

The data group mechanism allows a driver to flexibly adapt to multiple operating modes.

Safety Function Design: STO and SS1

The manual extensively elaborates on the implementation of safety functions in accordance with DIN EN 61800-5-2 (equivalent to IEC 61800-5-2), which is a key requirement for modern drive systems.

1. Safe Torque Off (STO):

The STO function is designed to prevent the motor from accidentally starting. After activation, the pulse enable power supply is cut off through the safety relay (option K80) to ensure that the power semiconductor cannot generate a rotating magnetic field and the motor is in a torque free state. Important reminder: STO is not an electrical isolation and cannot provide protection against electric shock; And it does not enable parking itself, it must be activated after the drive has come to a complete stop, otherwise the motor will stop freely. Additional mechanical braking is required for vertical axes, etc.

2. Safe Stop 1 (SS1- Safe Stop 1):

SS1 is a controlled safety stop. After triggering, the driver first decelerates and stops along the emergency stop slope. After a safety monitoring delay, the STO function is automatically activated. This achieves behavior that complies with EN 60204-1 stopping category 1.

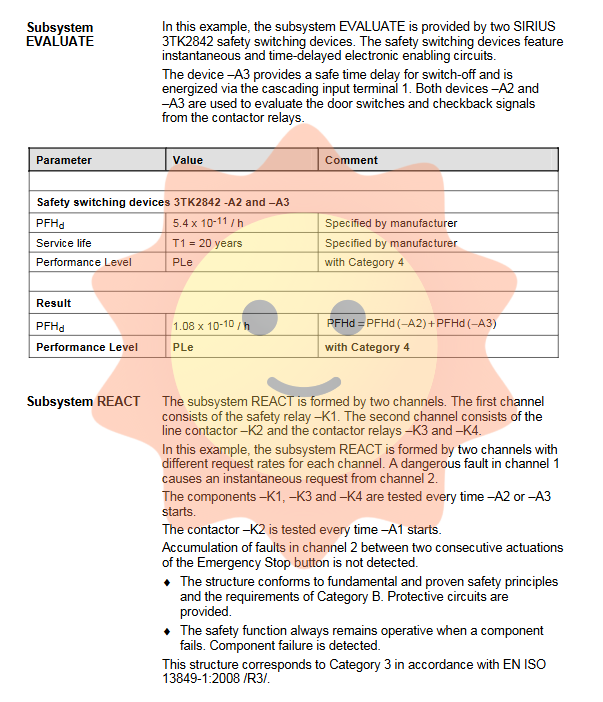

3. Application examples and performance level (PL) calculation:

The manual provides detailed circuit diagram examples, such as combining emergency stop button and protective door monitoring with STO or SS1 functions. Each example follows the safety architecture of "detection evaluation response" and has undergone detailed performance level (PL) calculations to demonstrate its ability to achieve the required PLr=d (according to EN ISO 13849-1). The calculation takes into account the average time to failure (MTTFd), diagnostic coverage (DC), and measures to resist common cause failures (CCF) of sensors (such as emergency stop buttons, position switches), evaluation units (such as Siemens SIRIUS safety relays), and actuators (safety relay K1, main contactor K2). These examples demonstrate that solutions that meet high safety standards can be constructed through a dual channel structure (such as pulse cutoff+main contactor disconnection) and appropriate diagnostics.

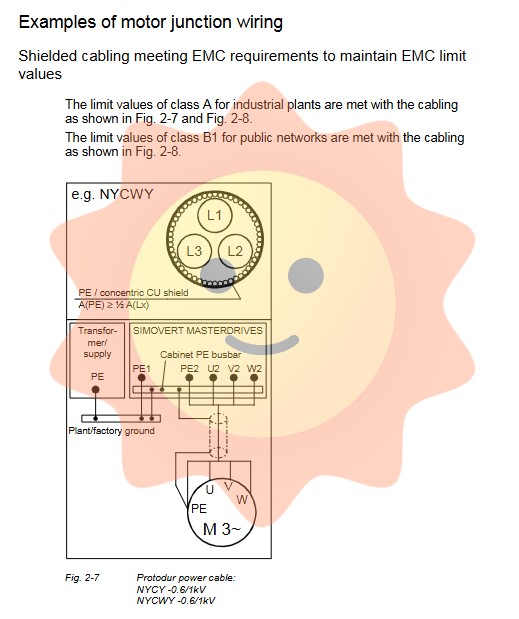

Electromagnetic Compatibility (EMC) Design Criteria

The frequency converter is both a high-frequency interference source (derived from fast switching of power semiconductors) and a potential interference receiver (affecting control circuits). The manual emphasizes that installing an incoming filter alone is not enough to ensure the EMC of the entire system.

The core principles include:

Partition concept: Separate interference sources (frequency converters, braking units, contactors) from sensitive equipment (controllers, sensors) in space (minimum distance of 20cm) inside the cabinet, preferably using grounded metal partitions.

Cable wiring: Power cables and signal cables must be laid separately. The motor cable must be shielded, and both ends of the shielding layer must be grounded.

Grounding and Connection: All metal cabinet components should be interconnected through a large area of metal surface (non painted surface to painted surface) to ensure a low impedance grounding network.

Signal cable processing: Digital signal cables such as encoders and transformers need to use shielded cables with both ends grounded. To avoid low-frequency interference (humming), analog signal cables can be grounded at one end of the receiving end and grounded at the other end through a capacitor (such as 10nF) to maintain high-frequency shielding continuity.

Filter installation: The RF interference suppression filter should be installed near the frequency converter and on the same unpainted metal mounting plate as the frequency converter to ensure good high-frequency electrical contact.

Following these rules, combined with the use of recommended incoming reactors and filters, can ensure that the drive system meets the emission and immunity requirements for industrial environments (secondary environment) in EN 61800-3 standard.

6GK1900-0AB00

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA