Siemens SINAMICS DCM DC Converter and Control Module

Electronic module: Integrated control unit (CUD) with reserved rotatable bracket slots, supporting additional CUD expansion to enhance control flexibility and redundancy.

Power section: A fully controlled three-phase bridge circuit is constructed using thyristors, which are divided into two driving types - two quadrant driving (B6C structure) and four quadrant driving ((B6) A (B6) C structure), to meet the speed and braking requirements under different operating conditions.

Cooling system: Equipment with a rated DC current ≤ 125A adopts a self ventilated design, while equipment with a rated DC current ≥ 210A is equipped with an integrated fan for forced air cooling to ensure stable operation of power components.

Excitation power section: Standard single quadrant excitation power unit (including freewheeling circuit), optional non excitation version or two quadrant excitation version (suitable for high dynamic excitation current change scenarios), and integrated excitation overvoltage protection function.

Power supply and operation unit: including electronic device power supply; Standard BOP20 operation panel, AOP30 advanced operation panel requires additional purchase.

Siemens SINAMICS DCM DC Converter and Control Module

Core components of the product

The SINAMICS DC MASTER series DC converter consists of multiple key functional modules, which work together to achieve DC drive control. The specific components and functions are as follows:

Electronic module: Integrated control unit (CUD) with reserved rotatable bracket slots, supporting additional CUD expansion to enhance control flexibility and redundancy.

Power section: A fully controlled three-phase bridge circuit is constructed using thyristors, which are divided into two driving types - two quadrant driving (B6C structure) and four quadrant driving ((B6) A (B6) C structure), to meet the speed and braking requirements under different operating conditions.

Cooling system: Equipment with a rated DC current ≤ 125A adopts a self ventilated design, while equipment with a rated DC current ≥ 210A is equipped with an integrated fan for forced air cooling to ensure stable operation of power components.

Excitation power section: Standard single quadrant excitation power unit (including freewheeling circuit), optional non excitation version or two quadrant excitation version (suitable for high dynamic excitation current change scenarios), and integrated excitation overvoltage protection function.

Power supply and operation unit: including electronic device power supply; Standard BOP20 operation panel, AOP30 advanced operation panel requires additional purchase.

General Technical Specifications

1. Standard compliance

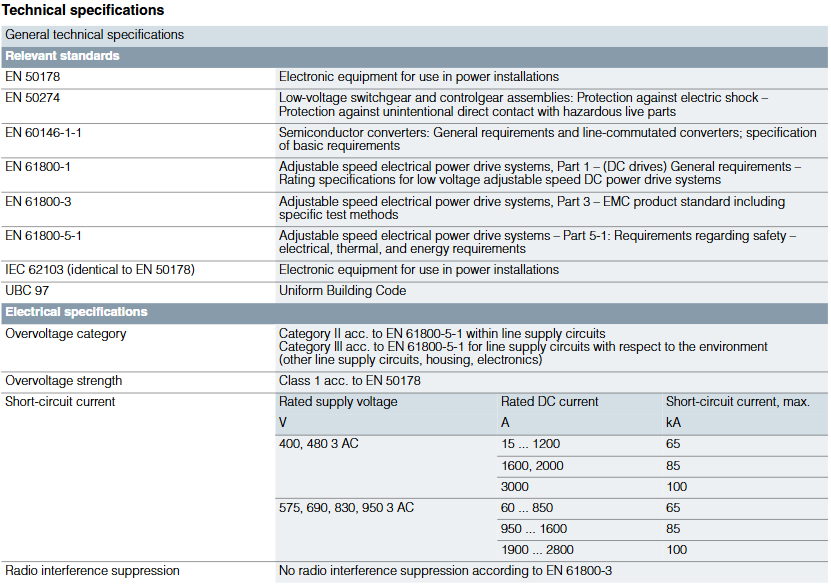

The product complies with multiple international and industry standards to ensure electrical safety, electromagnetic compatibility, and operational reliability. The core standards are listed in the table below:

Standard Number, Standard Name, and Scope of Application

EN 50178/IEC 62103 Electronic Equipment Standard for Power Facilities

EN 50274 Low voltage switchgear and control equipment components: Protection against electric shock (preventing accidental direct contact with hazardous live parts)

EN 60146-1-1 Semiconductor converters: General requirements and specifications for grid commutated converters

EN 61800-1 Adjustable Speed Electric Drive Systems Part 1: (DC Drive) General Requirements and Rating Specification for Low Voltage Adjustable Speed DC Drive Systems

EN 61800-3 Adjustable Speed Electric Drive Systems Part 3: Electromagnetic Compatibility (EMC) Product Standard with Specific Test Methods

EN 61800-5-1 Adjustable Speed Electric Drive Systems Part 5-1: Safety Requirements (Electrical, Thermal, and Energy Related)

UL 508 C Power Conversion Equipment UL Standard (575V and below equipment certified, UL file number E203250)

2. Electrical safety and performance

Overvoltage level and strength: The overvoltage level of the power supply circuit is EN 61800-5-1 Class II, which is Class III relative to the environment (other power supply circuits, enclosures, electronic devices); The overvoltage strength meets the EN 50178 Class 1 standard.

Short circuit current: Different combinations of supply voltage and rated DC current correspond to different maximum short-circuit currents. For example, in a 400/480V three-phase AC power supply, the maximum short-circuit current for equipment with a rated DC current of 15-1200A is 65kA, and for equipment with a rated DC current of 3000A, it can reach 100kA.

Radio interference suppression: The radio interference suppression function that complies with the EN 61800-3 standard is not configured. Additional accessories need to be purchased to meet the relevant requirements.

3. Stability of closed-loop control

Based on the thermal operation status of the equipment (rated motor speed), under specific premise conditions (ambient temperature ± 10 ℃, supply voltage ± 10%/-5%, temperature coefficient of the speed measuring generator with temperature compensation 0.15 ‰/10 ℃, constant given value), the control accuracy is as follows:

Pulse encoder operation+digital setpoint: speed deviation ∆ n=0.1% rated motor speed

Simulated speedometer+simulated setpoint: speed deviation ∆ n=0.006% rated motor speed

4. Environmental and mechanical parameters

Specific requirements for parameter categories

Basic protection level IP00 (EN 60529); Devices with ≤ 850A can be upgraded to IP20 through the "IP20 Upgrade Installation Kit"; Electrical safety level EN 61140 Class 1

Temperature range operation: ≤ 125A equipment 0-45 ℃, ≥ 210A equipment 0-40 ℃ (high temperature requires capacity reduction); Storage/transportation: -40-70 ℃

Relative humidity ≤ 95% (at 24 ℃), annual average ≤ 75% (at 17 ℃), condensation is strictly prohibited

Climate grade EN 60721-3-3 3K3

Insulation pollution level EN 61800-5-1 Class 2, condensation is strictly prohibited

Installation height ≤ 1000m altitude (100% load capacity); 1000-5000m altitude needs to refer to the derating specifications

Mechanical strength vibration: storage of 1M2 (EN 60721-3-1), transportation of 2M2 (EN 60721-3-2), constant deflection of 0.075mm during operation at 10-58Hz/constant acceleration of 10m/s ² during 58-200Hz; Impact: 100m/s ² (11ms, EN 60068-2-27 Ea) during operation

Mean Time Between Failures (MTBF)>170000 hours

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands