SINAMICS A10: Intelligent Servo Drive System with Integrated Safety and Efficient Debugging

SINAMICS A10: Intelligent Servo Drive System with Integrated Safety and Efficient Debugging

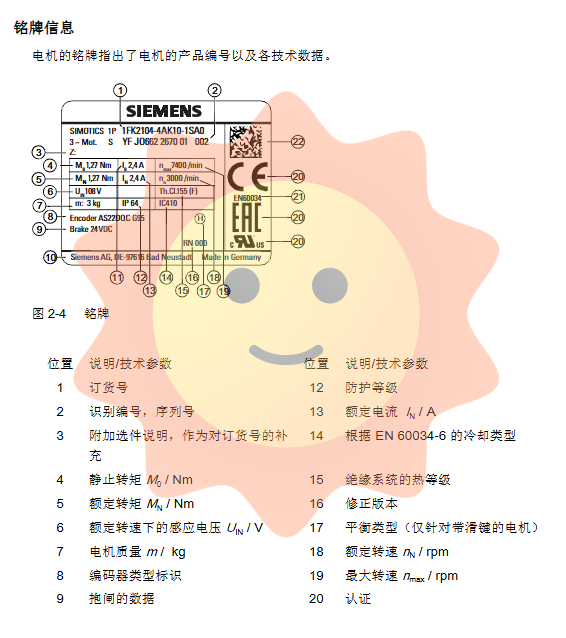

Introduction

SINAMICS A10 is a compact single axis servo drive system launched by Siemens, designed specifically for high dynamic performance industrial automation applications. The system is perfectly matched with SIMOTICS S-1FK2 servo motors and pre installed MOTION-CONNECT cables, forming a highly integrated, easy to debug, and safe reliable drive solution. This article is based on its official operating manual (firmware version V5.2, January 2019), providing in-depth analysis of its system architecture, core security functions, installation and debugging process, and key technical points, providing engineers with comprehensive professional references.

System Overview and Design Philosophy

The SINAMICS A10 drive system consists of three core components: SINAMICS A10 driver, SIMOTICS S-1FK2 servo motor, and MOTION-CONNECT cable using One Cable Connection (OCC) technology. The system is connected to the upper controller (such as SIMATIC S7-1500) through PROFINET and supports real-time (RT) and synchronous real-time (IRT) communication.

The design of the driver emphasizes compactness and high performance, with a power range covering 0.1 kW to 0.75 kW for single-phase 230V version and 0.4 kW to 7 kW for three-phase 400V version. Its key features include:

Integrated safety functions: Safety functions that comply with SIL 2/PL d/Cat.3 standards can be achieved without the need for external components.

Optimization matching: The driver has undergone servo control optimization for the 1FK2 motor to ensure optimal dynamic response.

Network server integration: Built in web server, supports debugging, diagnosis, and parameter settings through standard browsers, without the need for specialized software.

Core safety function: Driver Integrated Safety

Safety is the core advantage of SINAMICS A10. The integrated security functions are divided into two categories, both of which perform security monitoring with a cycle of 4ms.

1. Basic Functions

Included in the standard supply scope of the drive, no additional authorization is required:

Safe Torque Off (STO): Complies with EN 60204-1 stop category 0, immediately blocks motor torque output to prevent accidental restart. Suitable for situations where the motor can safely stop by inertia.

Safe Stop 1 (Time Controlled) (SS1-t): Meets Stop Category 1, drives the braking along the OFF3 slope, and triggers STO after a preset delay time. Suitable for situations where the load friction torque is insufficient or there is a risk of inertia parking. There are two modes to choose from: Drive Self Control (SS1-t) or Stop by External Controller (SSSE-t).

Safe Brake Control (SBC): linked with STO, controls the motor brake to close, preventing the hanging load from sagging. Suitable for applications such as lifting and coiling.

2. Extended Functions

Additional license activation is required to provide richer security monitoring:

Safe Stop 2 (SS2): Stop the motor and reliably monitor the stationary position (transition to SOS state), and resume operation without returning to zero after cancellation.

Safe Operating Stop (SOS): Reliable closed-loop monitoring of the stationary position of the drive to resist external forces.

Safely Limited Speed (SLS): Safety monitors whether the speed exceeds the preset limit (up to 4 switchable gears), and triggers a preset stop response if it exceeds the limit.

Other functions include Safety Speed Monitoring (SSM), Safety Direction (SDI), Safety Limited Acceleration (SLA), and Safety Braking Test (SBT) for diagnosing brake performance.

The safety function can be controlled through Fault Safety Digital Input (F-DI) or PROFIsafe communication (recommended message 30 for basic functions and message 901 for extended functions). The system has detailed response time analysis and error tolerance processing to ensure the reliability and timeliness of safety response.

Installation and configuration points

Correct installation and configuration are the foundation for reliable system operation.

1. Electromagnetic compatibility (EMC) installation

To ensure stable operation, EMC guidelines must be followed:

Control cabinet: Use metal mounting plates with good grounding, and install shielding plates for cable shielding layer extraction.

Cable wiring: Distinguish between high interference level cables (motor cables, brake resistor cables) and low interference level cables (signal/data cables). The two should be laid separately, with a minimum spacing of 25cm, and intersect at a right angle. Be sure to use shielded cables with both ends grounded.

Motor cable length: Depending on whether an external filter is used and whether a DC bus is shared, the allowed cable length ranges from 10 meters to 250 meters and must strictly comply with the manual regulations.

2. Grid connection

Support TN, TT, and IT power grid systems. When operating in IT power grids or phase line grounding systems, special attention should be paid to removing specific grounding screws for single-phase drivers, and additional isolation transformers may be required for three-phase drivers.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA