Siemens SINUMERIK 840C CNC System Installation and Debugging Guide

Siemens SINUMERIK 840C CNC System Installation and Debugging Guide

Siemens SINUMERIK 840C is a high-performance CNC system widely used in the field of machine tool control. Combined with the SIMODRIVE 611-D digital drive system, high-precision and high dynamic response motion control can be achieved. This article is based on the official SINUMERIK 840C SIMODRIVE 611-D Installation Guide (version 09.2001), which systematically outlines the entire process of installation, configuration, and debugging, covering various aspects from hardware preparation to software optimization, from PLC integration to driver debugging, providing a complete and professional technical reference for machine tool manufacturers and debugging engineers.

System Overview and Preparation Before Installation

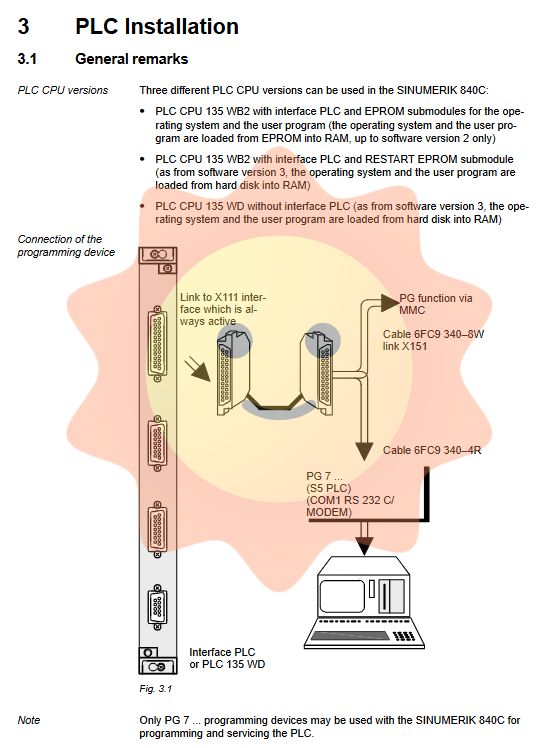

The SINUMERIK 840C system adopts a modular design, including core units such as NCK (numerical control core), MMC (human-machine communication), and PLC (programmable logic controller). The system supports both analog and digital drivers, with SIMODRIVE 611-D being a fully digital driver system with stronger communication capabilities and debugging flexibility.

The following prerequisites must be met before installation:

The mechanical and electrical installation of the machine tool has been completed, and all axes are ready for operation.

The customer's PLC program has been written and preliminarily tested.

The measurement system (such as grating ruler, encoder) has been installed and wired to the SINUMERIK interface.

All cables have been connected, and the shielding layer is grounded according to the interface instructions.

The grounding system complies with DIN VDE 0160 standard and adopts star shaped grounding points for centralized grounding.

The customer needs to provide personnel support for interface debugging, machine operation, and PLC program verification.

Visual Inspection is a critical step that requires focused inspection of:

Module handling: Electrostatic sensitive devices (MOS modules) require special protection to avoid direct contact with printed circuits.

Grounding system: Ensure that the grounding wire has no loops, the cross-section meets the requirements, and achieve equipotential connection.

Position encoder: installed in accordance with specifications (such as air gap, coupling), correctly wired and well shielded.

Cable laying: Power cables and control cables are routed separately to avoid grounding loops, and the minimum bending radius meets the requirements.

Shielding and anti-interference: All cable shielding layers entering and exiting the control cabinet must be grounded through connectors, and relays and motors must be equipped with suppressors.

Operation panel: The buttons, indicator lights, and display functions are normal.

Overall status: The module is securely installed, the front cover screws are tightened (grounded), and the accessory package is complete (including logs, spare parts list, transparent cover plate, etc.).

Hardware installation and electrical inspection

1. Voltage and functional testing

After the system is powered on, NCK and MMC will perform a self-test program. If a system program verification error is detected in the NCK area, the red LED will continue to flash and enter a stop state. The MMC area will display startup information, including memory testing, interrupt controller detection, etc. Starting from software version 4, the system will automatically perform a hard disk consistency check upon startup, and it is recommended to perform it regularly to free up disk space.

2. Data loading process (software version 2 and above)

When the system starts up, data is loaded from the MMC hard drive into NCK in three stages:

Stage 1: Load NCK system programs (such as during DRAM data loss or forced startup).

Stage 2: Load user data, including user customized UMS (if any) and NC data files under the user branch.

Stage 3: Load standard workpiece data.

3. Standard/export version identification

Due to export controls, 840C offers standard version (840C) and export version (840CE). The export version prohibits 5D interpolation, interpolation and table compensation (IKA) and other functions. The system software version determines the control properties, and replacing or upgrading the software may require an export license for the control system. The control version can be identified through delivery notes, invoices, and software packaging labels. After startup, the export version will display an additional character "E" in the service screen.

Software Configuration and Standard Startup

1. Universal reset and standard startup (software version 3 and above)

For newly installed or data lost systems, it is necessary to enter the "universal reset mode" for standardized startup. In this mode, the following key operations can be performed:

Format NCK user memory: Clear user data (machine data, R parameters, tool data, etc.) from SRAM to ensure consistent initial state.

Delete digital drive configuration file: Only applicable to digital drive systems.

Save PLC user program to hard drive: Save the current PLC program as an ANW-PROG file for easy loading in the future.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA