Siemens SITOP UPS 1600/UPS 1100: High reliability DC uninterruptible power supply system for industrial automation

Siemens SITOP UPS 1600/UPS 1100: High reliability DC uninterruptible power supply system for industrial automation

In the field of industrial automation, the continuity and stability of power supply are fundamental to ensuring uninterrupted operation of production lines, control systems, and critical data equipment. The UPS 160 DC uninterruptible power supply (DC-UPS) module and UPS 110 battery module in the Siemens SITOP family jointly build an efficient, intelligent, and easy to integrate 24V DC uninterruptible power supply solution. This system is designed specifically to buffer the output current of the SITOP series 24V load power supply, with a rated current coverage of 10A, 20A to 40A, and can support different cut-off outputs up to 40A through intelligent battery management.

System Core Architecture and Product Overview

SITOP UPS1600, as the core control unit of the system, is a compact built-in device that can be installed on TH35-15/7.5 standard rails (EN 60715). It is not a traditional AC-UPS, but a buffer module designed for industrial DC busbars. Its input is directly connected to the output of the front-end 24V DC power supply (such as SITOP PSU8200, etc.), the load is connected to its output terminal, and the UPS 110 battery module is connected to a dedicated BAT terminal. When the input voltage drops or fails, the system can switch to battery power within milliseconds to ensure the continuous operation of the load.

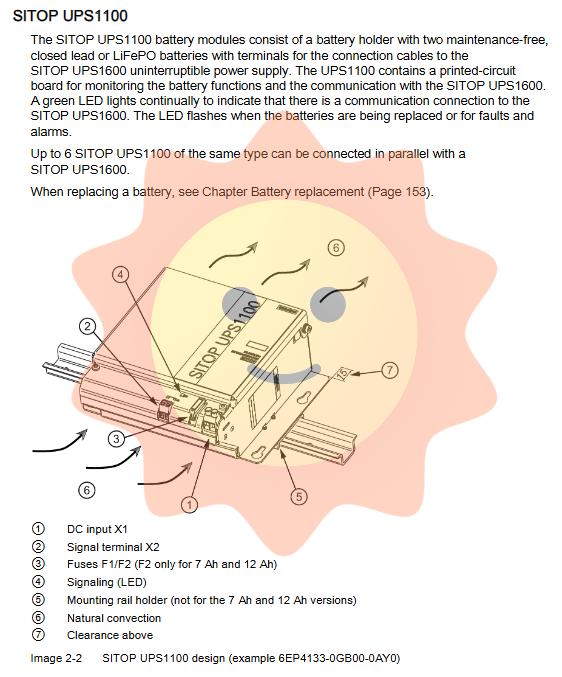

The UPS 110 battery module serves as an energy storage unit, offering multiple capacity options from 1.2 Ah to 12 Ah, using maintenance free lead-acid gel batteries or 5 Ah capacity LiFePO4 batteries. It integrates a monitoring circuit board internally and exchanges data with UPS1600 through Energy Storage Link - an independent two-wire communication link. This design enables the UPS1600 to automatically identify parallel battery types (up to 6 modules of the same model) and select the optimal temperature controlled charging curve, greatly extending battery life. This link also continuously monitors the battery readiness status, power cable (disconnection detection), and charging status (voltage, current), checks the connection every 20 seconds, and automatically performs a load test every 4 hours (default).

Outstanding technical features and performance advantages

High dynamic overload capacity: To meet the instantaneous high starting current requirements of loads such as PLCs and industrial PCs, the UPS1600 has excellent overload performance. It can withstand up to 300% of the rated current within 30ms, or 150% of the rated current per minute for up to 5 seconds, ensuring smooth start-up of large loads even in buffer mode.

Intelligent battery management and diagnosis: The system automatically identifies the rated parameters of the SITOP UPS 110 battery module, realizes temperature compensation charging, and monitors its health status. All diagnostic data and alarm information can be obtained through USB, integrated web server, or PROFINET/Ethernet interface. For non coding third-party batteries, although the diagnostic function is limited, they can still be used.

Flexible parameter configuration and operating mode:

Switching threshold and buffer time: There are two rotary encoding switches on the front of the device, which can be used to hardware set the battery cut-off voltage (21.0V -25.0V) and buffer time (30 seconds - MAX). For models with interfaces (-1AY0 with USB, -2AY0 with PROFINET), the switch provides the REN position, allowing for more detailed settings through software such as TIA Portal or SITOP UPS Manager.

Multiple jumper configurations: Rich functions can be achieved through jumpers on the signal connector (X2):

ON/OFF (pins 9-10): Enable or disable buffer mode. The jumper is connected at the factory and buffering is allowed. External floating contacts (resistance<10 Ω) can also be used as a substitute for remote control.

INTERRUPT (pins 13-10): Enable output voltage interruption function. When the set buffer time ends and the input voltage has been restored, the output will be interrupted for a configurable time (default 5 seconds, adjustable with interface devices) to reset the connected PC/device.

START (pins 14-10): Implement the "battery start" function. When there is no input voltage, short circuiting this circuit with a button can command the UPS to start from the battery, such as for starting a generator.

Charging current setting (pins 10/11/12): For non coding batteries, the charging current size can be set through jumper combinations.

Rich status indication and relay output: The device is equipped with 8 LED indicator lights, which respectively display the operating mode (OK/BAT), battery charging status (>85%), buffer ready (ALARM), battery fault, etc. In addition, three relay contacts are provided: REL1 indicates normal/buffer mode, REL2 indicates buffer ready/alarm, and REL3 (normally open) indicates that the selected buffer time can be achieved or the charging status is>85%.

Powerful communication and integration capabilities:

PROFINET/Ethernet interface (-2AY0): Integrated dual port switch, supporting PROFINET IO (compliant with IEC 61158) and standard TCP/IP communication. Support hardware configuration, parameter setting, data cycling/non periodic exchange, and diagnosis through STEP 7 (TIA Portal or Classic version).

USB interface (-1AY0): Used to connect to a PC and run the free SITOP UPS Manager software provided by Siemens for configuration, monitoring, and data analysis.

Integrated web server: No additional software is required, remote access can be achieved through a web browser to view real-time data, alarm history, trend charts, and perform user management (V2.1 and above versions support HTTPS and write access). The web server is not activated by default when it leaves the factory (starting from V2.1).

Seamless integration into the industrial automation ecosystem

The design of SITOP UPS1600 fully embodies the concept of "fully integrated automation".

TIA Portal Integration: UPS1600 can appear directly in the hardware directory from TIA Portal V13 (in conjunction with HSP) or by installing GSD files (TIA Portal V12). Users can drag it into the network view, assign controllers, and easily configure battery modules just like configuring other PROFINET devices. All parameters, such as buffer time, switching threshold, charging parameters, and web server settings, can be centrally configured in the device properties and downloaded to the device.

SITOP UPS Manager software: This free software running on Windows XP/7 provides more powerful local monitoring and management capabilities. It supports connection via USB or Ethernet to achieve:

Comprehensive device parameter configuration and firmware updates.

Trigger custom applications based on events such as power failure, insufficient buffering time, and battery replacement (such as shutting down the computer, sending emails/SMS).

Intuitive trend chart display, showing the historical changes of parameters such as load current, input voltage, and remaining buffer time.

Master slave operation: Under Ethernet connection, a PC can be configured as the master station to manage other PCs acting as slave stations in the network and achieve coordinated shutdown of devices within the network.

OPC UA Server Function (since V4.71): Provides a non proprietary interface for standardized, cross platform data access, facilitating integration with higher-level MES or SCADA systems.

Integration with SIMATIC STEP 7 Classic: For users using STEP 7 V5.4 and above, UPS1600 can also be integrated into PROFINET IO systems for configuration, parameter allocation, and diagnosis by installing GSD files.

Key points of engineering design, installation, and maintenance

Safety and Regulations: The manual emphasizes at the beginning that the equipment must be operated by qualified personnel in accordance with relevant documents and safety regulations. Installation must comply with DIN/VDE or local regulations (such as EN 50272-2). The input 24V power supply must comply with the SELV standard (EN60950-1).

Installation and wiring:

UPS1600: The standard installation position is vertical, with the terminals facing downwards to ensure heat dissipation. Maintain a minimum distance of 50mm between the top and bottom. The power terminals (IN, OUT, BAT) support different wire diameters (such as the 10/20A model supporting 0.2-6mm ²), and require the use of cables with a temperature resistance of at least 90 ℃ (in compliance with UL508).

UPS 110: Supports wall mounted or rail mounted installation (some models). Installed in the coolest position of the control cabinet (such as the lower part). When connecting battery modules, it is necessary to ensure that the power line (X1) and communication line (X2) are correctly connected, and that the parallel connected battery modules have the same model and status as much as possible.

Maintenance: The battery is designed to be maintenance free, but has a certain lifespan (approximately 4 years at 20 ° C). SITOP UPS 1100 provides a convenient battery replacement process: open the cover, press and hold the replacement button for more than 2 seconds (LED flashing), remove the fuse, replace the battery with the same model, press and hold the button again to confirm, and then reinstall the fuse. The system will automatically reset the relevant running timers and counts.

Technical data and environmental adaptability

The system demonstrates a robust industrial grade design:

High efficiency: The full load efficiency can reach 97.5% -98.5%, with low power loss.

High MTBF: Under 40 ° C, rated load, and 24-hour operating conditions, the average time between failures exceeds 320000 hours.

Wide environmental range: The working temperature of UPS1600 is -25 ° C~+70 ° C (natural convection, derating is required at 70 ° C), and the storage temperature is -40 ° C~+85 ° C. The working temperature of the UPS 110 battery module is usually 0 ° C~+40 ° C (some new versions support -15 ° C~+50 ° C).

Altitude impact: When operating above 2000 meters, for every 1000 meters increase, the output current needs to be reduced by 7.5%, or the ambient temperature needs to be reduced by 5K.

Complete certification: equipped with multiple international certifications such as CE, cULus, ATEX/IECEx explosion-proof (II 3G Ex nA nC IIC T4 Gc), CB, GL classification society, etc.

Strong electromagnetic compatibility: Complies with EN 61000-6-2 (industrial environment immunity) and EN 61000-6-3 (residential emission) standards, and has good ESD, EFT, and Surge immunity capabilities.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA