Molex SST-ESR2-CLX-RLL and SST-SR4-CLX-RLL communication modules

PC hardware should have at least an Intel Pentium 4 processor, 512MB of memory, and 100MB of available hard disk space; Suggest a 17 inch/19 inch (1280 × 1024 and above resolution) monitor; CD/DVD drive, power cable, Ethernet cable, keyboard and mouse required

The PAC/PLC power ESR2 module consumes 5VDC 850mA and 24VDC 1.75mA; The SR4 module consumes 5VDC 1004mA and 24VDC 1.75mA. Please refer to the CLX 5000 modular installation and operation manual to calculate the total power load

The PC operating system supports Windows XP, Vista, 7, and 8

Other requirements: 1. Support for Rockwell Automation RSLogix 5000 Additional Instructions (AOI) requires RSLogix 5000 V16 or above, module firmware must be 2.10.2 or above (general configuration file) or 2.12.1 or above (additional configuration file/AOP), BCMS software must be 1.9 or above

Molex SST-ESR2-CLX-RLL and SST-SR4-CLX-RLL communication modules

System and hardware requirements

(1) System requirements

Category specific requirements

PC hardware should have at least an Intel Pentium 4 processor, 512MB of memory, and 100MB of available hard disk space; Suggest a 17 inch/19 inch (1280 × 1024 and above resolution) monitor; CD/DVD drive, power cable, Ethernet cable, keyboard and mouse required

The PAC/PLC power ESR2 module consumes 5VDC 850mA and 24VDC 1.75mA; The SR4 module consumes 5VDC 1004mA and 24VDC 1.75mA. Please refer to the CLX 5000 modular installation and operation manual to calculate the total power load

The PC operating system supports Windows XP, Vista, 7, and 8

Other requirements: 1. Support for Rockwell Automation RSLogix 5000 Additional Instructions (AOI) requires RSLogix 5000 V16 or above, module firmware must be 2.10.2 or above (general configuration file) or 2.12.1 or above (additional configuration file/AOP), BCMS software must be 1.9 or above

2. Support for RSLogix 5000 additional configuration files (AOP) requires RSLogix 5000 V15 or above version, module firmware 2.3.0 or above, BCMS software 1.7.0 or above, and AOP only supports maximum input/output/status INT size (250, 248, 250), small size requires 1756 universal configuration file

(2) Hardware and Packaging

package contents

The module model includes items and quantities

SST-ESR2-CLX-RLL 1 communication module, 2 RJ45 to DB9 serial cable adapters, 1 Windows system installation CD (including BCMS software), PDF versions of the CD including user guide, Siemens Industrial Ethernet protocol guide, Modbus TCP/serial protocol guide

SST-SR4-CLX-RLL 1 communication module, 4 RJ45 to DB9 serial cable adapters, 1 Windows system installation CD (including BCMS software), CD containing user guide, Modbus serial protocol guide PDF version (Siemens Industrial Ethernet, Modbus TCP protocol guide PDF included but not applicable)

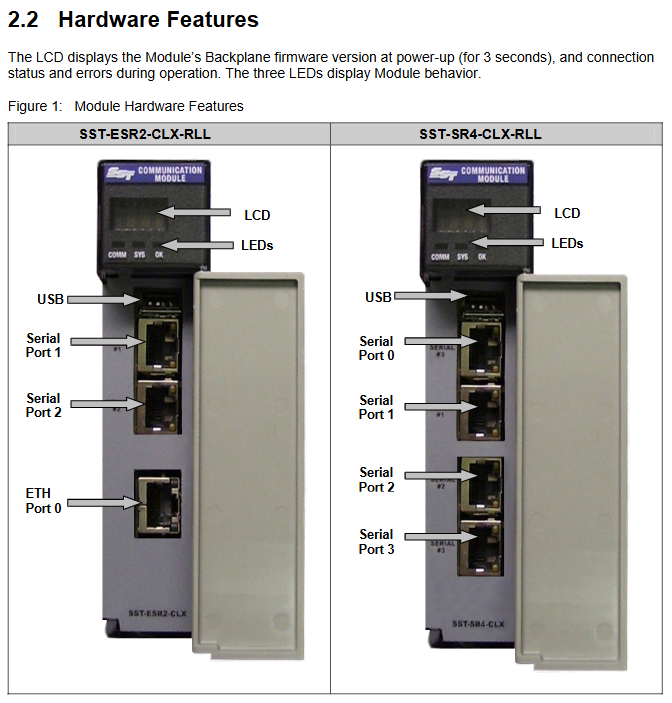

Hardware features: All include status LEDs (COMM, SYS, OK, indicating communication/connection/initialization status respectively), RJ45 serial interface (connecting RS232/422/485 devices with transmit/receive indicator lights), USB configuration port (downloading configuration/upgrading firmware); ESR2 additionally includes an RJ45 Ethernet interface (connected to industrial networks with activity/link indicator lights), while SR4 does not have an Ethernet interface; All have self-locking tongue fixing modules, and LCD displays firmware version, connection status, IP address, and other information.

Core functions and software

(1) Core functions of the product

Differences and Commonalities of Modules

Function SST-ESR2-CLX-RLL SST-SR4-CLX-RLL

Number of interfaces: 1 Ethernet port+2 serial ports+4 serial ports

Supports protocol Modbus TCP/serial, Siemens S5/S7 communication only Modbus serial communication

Common feature 1. Supports two database addressing modes: default and extended. In default mode, 0-699 address mapping is used for CLX input/output/status tables. In extended mode, 30K address mapping can be customized

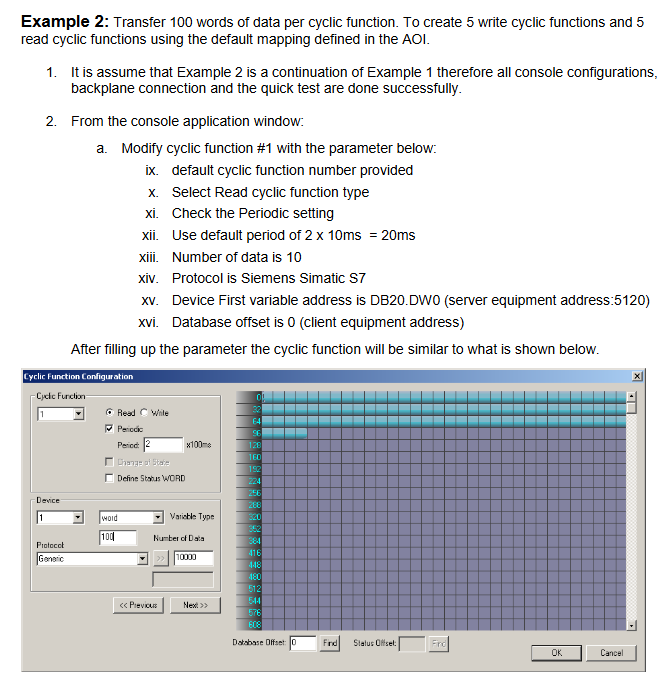

2. Support cyclic function (read and write data periodically, up to 255 per channel), which can be dynamically triggered

3. Supports AOI/AOP and CIP messaging (reading and writing databases, triggering cyclic functions)

4. Supports remote rack configuration, Listen Only mode, and can be configured as client/server (master-slave) mode

Protocol support details: Modbus supports function codes such as FC3 (read multiple registers), FC6 (write single registers), FC16 (write multiple registers), etc; Siemens S5/S7 supports reading and writing of variable types such as ABx/AWx, EBx/EWx, MBx/MWx, DBx.DBx, etc.

(2) Software and Tools

BCMS software: Brad Communication ™ The SST backplane communication module software includes Configuration Manager (managing configuration files, such as creating/uploading/downloading configurations, modifying IP addresses), Console (configuring ports/protocols/devices, creating cyclic functions, including tools such as PCInit/ReadWait/WriteWait). After installation, the configuration files, AOI files, and firmware are stored in the corresponding system paths (Windows XP/7 paths differ).

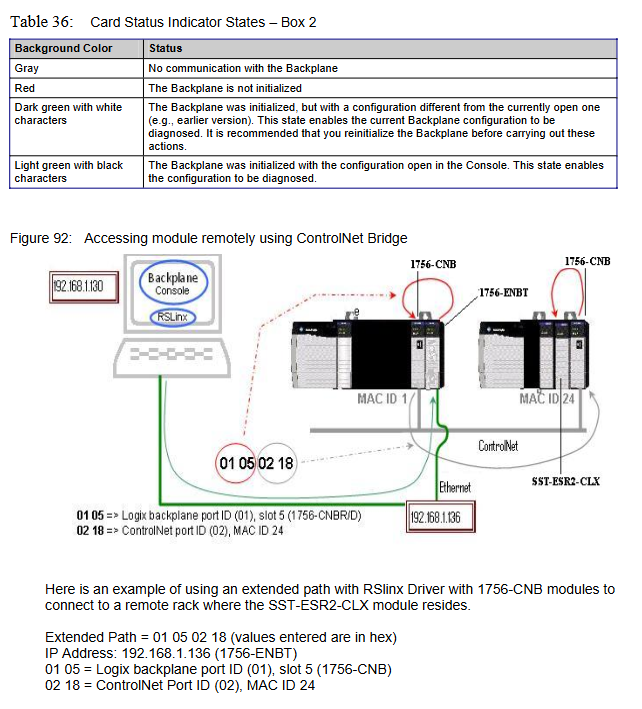

Diagnostic and management tools: including Visucyc (monitoring cyclic function status), Network Diagnostic (diagnosing ESR2 Ethernet activity), Firmware Installer (upgrading firmware), etc., supporting module connection through USB, RSLinx, TCP/IP, and other methods.

Configuration and Operation Guide

(1) Quick configuration process

Backplane communication verification: The module supports live plugging and unplugging (RIPP). During installation, align the guide rail and insert it into the rack. Configure the EtherNet/IP driver through RSLinx and browse the rack to confirm that the module is recognized (ESR2 product code 53, SR4 product code 54).

Module configuration (RSLogix 5000)

AOP configuration (recommended): You need to install the AOP installation package first, add the SST-ESR2/SR4-CLX-RLL module to RSLogix 5000, configure the slot, connection type (Output w/Status/Sten Only), RPI (5-750ms), program mode output status (such as Zero CyclicRuns), and ensure that the configuration name is consistent with the module.

General configuration file: Add 1756-MODULE, set communication format (such as Data INT with Status), assembly instance and size for input/output/configuration/status (such as input instance 1, size 250).

Initialization and Address Mode Switching: Initialize the module through Console's PCInit; The database address mode can be switched in Configuration Manager. The default mode maps the CLX table from 0-699, and the extended mode allows customization of input/output/status addresses and lengths (firmware 2.10.2 or above is required).

(2) Typical Configuration Example

Modbus TCP configuration: ESR2 can be configured as a server (select Modbus TCP protocol), client (add Modbus device, set IP address), or both client and server, creating cyclic functions (set cycle, data volume, device address, database offset).

Modbus serial configuration: Both modules can be configured as slaves (select Modbus RTU/ASCII Slave) or hosts (add Modbus slave devices, set slave numbers), supporting multi-channel master-slave hybrid configuration.

Siemens S7/S5 configuration: Only supported by ESR2, can be configured as a server/client, adding devices such as S7 300/400/1200, creating cyclic functions to read and write variables such as DBx.DWx.

Compliance and Support

(1) Compliance certification

Compliant with CE/EU, RoHS, FM (Class 1 Div 2 Groups A-D), FCC, Korean certification, RINA certification, electrical safety complies with EN 61010-1, EMC complies with EN 61000-6-2/4.

(2) Warranty and Support

Warranty: According to Molex standard warranty terms, please refer to Appendix F of the document for details.

Technical Support: You can contact Molex Canada at 216 Bathurst Drive, Waterloo, Ontario, Canada N2V 2L7; Phone: 1.775.782.3611 or 1.800.227.5514 (US only), or visit the official website Bently.com for patent information and the latest documents.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands