ABB Procontic T200 Control System Hardware

ABB Procontic T200 Control System Hardware

Product positioning

Procontic T200 is a compact industrial automation control system designed for small and medium-sized industrial processes such as machinery manufacturing, light industry, water treatment, etc. It achieves logic control, data acquisition, and process monitoring through modular hardware design, while also considering flexibility and reliability.

Hardware composition and core modules

System architecture

Modular design: composed of central processing unit (CPU), input/output (I/O) modules, power module, communication module, and rack, supporting distributed expansion (connected to remote I/O stations through bus), with a maximum expansion of 2048 I/O.

Redundancy option: Supports CPU, power, and communication bus redundancy in critical scenarios to enhance the system's ability to withstand failures.

Core hardware modules

(1) Processor module (CPU)

Model examples: T200-CPU110, T200-CPU120, based on 16 bit/32-bit microprocessors, with computational capabilities supporting complex logic control (such as ladder diagram and functional block diagram programming).

Key parameters:

Program storage capacity: 128KB~512KB (non-volatile memory), supports online program modification.

Data storage: 64KB RAM (with battery backup, power-off data storage ≥ 72 hours).

Integrated communication interface: standard RS485 (supporting Modbus RTU), some models include Ethernet port (supporting TCP/IP).

(2) Input/Output (I/O) Module

Digital input module:

Models such as T200-DI16 (16 point DC input), supporting 24V DC signals, response time ≤ 1ms, optocoupler isolation (2500V AC), compatible with proximity switches, limit switches, and other sensors.

Digital output module:

Model such as T200-DO16 (16 point relay output), contact capacity 5A@250V AC/DC, Support inductive loads (requiring external current diodes); Or transistor output (24V DC, 0.5A/point), response time ≤ 0.1ms.

Analog module:

Input module (T200-AI8): 8-channel, supports 4-20mA/0-10V signals, resolution of 12 bits, sampling period of 100ms, compatible with temperature transmitters, pressure sensors, etc.

Output module (T200-AO4): 4-channel, 4-20mA output, accuracy ± 0.1% FS, used to drive actuators such as regulating valves and frequency converters.

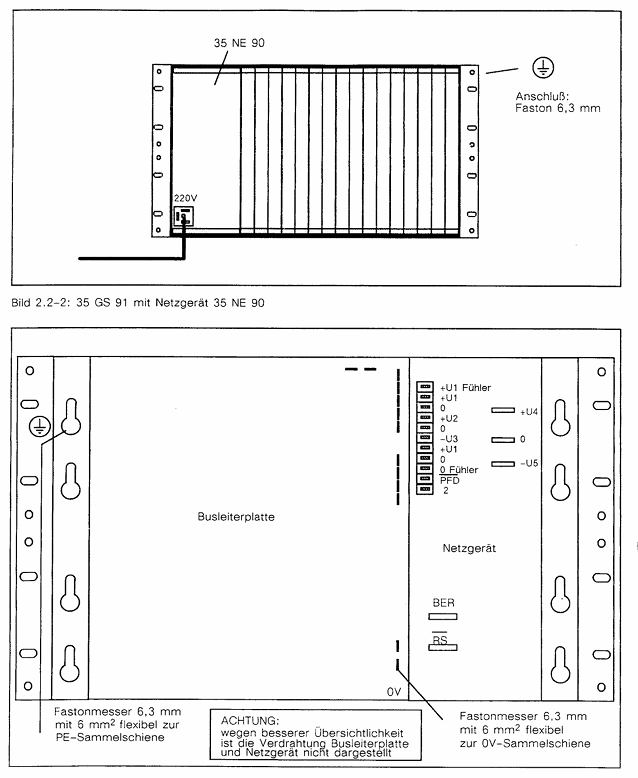

(3) Power module

Model: T200-PS24 (24V DC output), T200-PS110/220 (110V/220V AC input, 24V DC output), optional output current of 5A/10A, overload protection (150% load limited current), short circuit protection (self recovery).

When configuring redundant power supplies, it is necessary to achieve interference free switching through dedicated redundant modules.

(4) Communication and Expansion Module

Bus module: T200-BUS module supports PROFIBUS DP or MODBUS Plus bus, realizing communication between master station and remote I/O slave station, with a maximum transmission rate of 12Mbps and a distance of ≤ 1000m (without relay).

Ethernet module: The T200-ETH module provides a 10/100Mbps Ethernet port, supports TCP/IP and FTP, and is used to connect to HMI or SCADA systems on the upper computer.

Hardware installation and connection

1. Rack and module installation

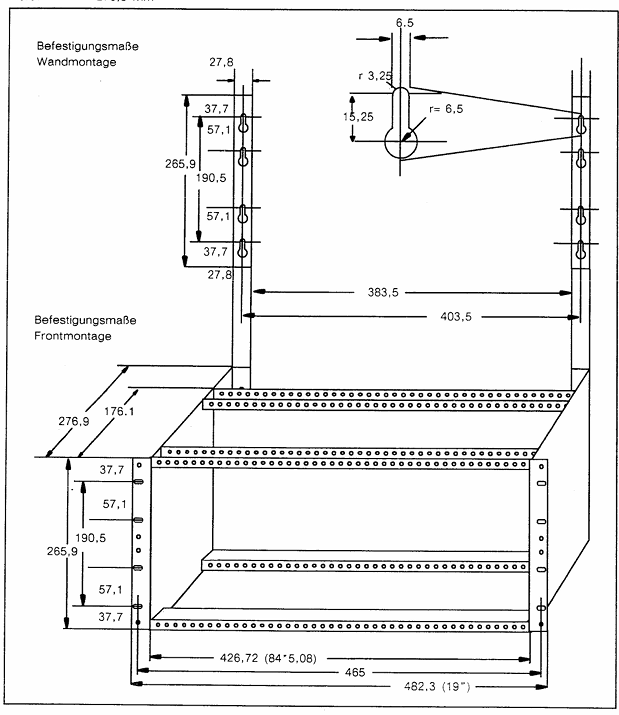

Rack specifications: Standard 3U rack (19 inches), supporting 16 module slots, with plug-in design for modules. The front panel screws need to be locked to prevent loosening during installation.

Installation environment: Operating temperature of 0-55 ℃, relative humidity of 5% -95% (no condensation), vibration level ≤ 5g (10~500Hz), and should be kept away from strong electromagnetic interference sources (such as frequency converters and high-power motors).

2. Electrical connection specifications

Power connection: The input side is connected to the protective grounding (PE), and the output side 24V DC "+" "-" should correspond to the I/O module. It is recommended to use a 1.5mm ² shielded wire with a single ended grounding of the shielding layer.

I/O wiring: Digital signals use 0.5mm ² wires, while analog signals require twisted pair shielded wires (with a distance of ≥ 30cm from the power line). The wiring terminal numbers correspond one-to-one with the module channels (such as AI1 corresponding to terminal 1/2).

Communication wiring: The PROFIBUS bus uses a dedicated bus cable (impedance 150 Ω) with terminal resistors (150 Ω) at both ends. The connector uses a D-type 9-pin plug to ensure good pin contact.

System Expansion and Compatibility

Local expansion: Connect up to 3 expansion racks through rack expansion interfaces, with a total I/O point count of no more than 2048 and an expansion distance of ≤ 1m (between racks).

Remote expansion: Connect remote I/O stations (such as T200-RIO) through the PROFIBUS DP bus, supporting up to 31 slave stations and a distance of up to 10km (with relays).

Compatibility: Supports communication with other ABB Procontic products (such as T300) and third-party devices (such as Siemens S7 series, Schneider Modicon series), and is compatible with OPC servers for data integration.

Application scenarios

Procontic T200, as a small and medium-sized distributed control system, is suitable for:

Logic control and production line linkage of packaging machinery and printing equipment;

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands