Okonite Type SP-OS ITC/PLTC Instrument Cable

Okonite Type SP-OS ITC/PLTC Instrument Cable

Product basic positioning

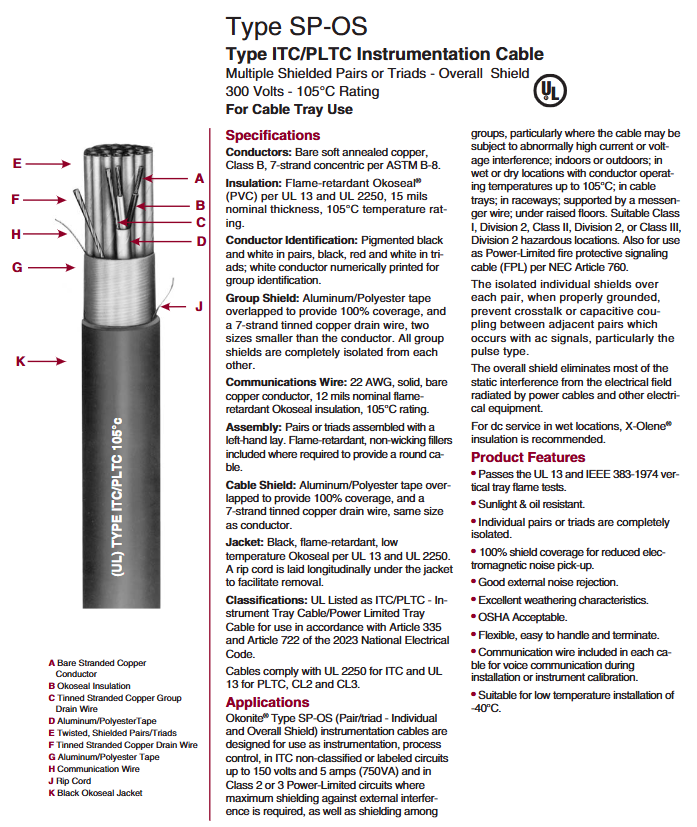

Okonite Type SP-OS cable belongs to the ITC/PLTC (Instrument Tray Cable/Power Limiting Tray Cable) category, with multi shielded pairs or three wire group structure and overall shielding design, rated voltage of 300 volts, temperature tolerance level of 105 ° C, designed specifically for cable tray scenarios, and meets multiple industry standards, suitable for electrical environments with high requirements for shielding and anti-interference.

Core specification parameters

(1) Conductors and Insulation

Category specific parameters

The conductor material is bare soft annealed copper, which meets the ASTM B-8 standard and adopts a 7-strand concentric structure; The communication cable is a 22 AWG solid bare copper wire with a 12 mil flame-retardant Okoseal insulation layer ® (PVC), Tolerant to 105 ° C

Insulation using flame retardant Okoseal ® (PVC) material, compliant with UL 13 and UL 2250 standards, nominal thickness of 15 mil, temperature rating of 105 ° C; X-Olene is recommended for special scenarios (DC applications in humid environments) ® insulation

The conductor identification lines are colored in black and white; The three line group consists of black, red, and white; White conductor with numbers printed on it, used for group identification

(2) Shielding structure

Group shielding: Using aluminum/polyester tape overlapping wrapping to achieve 100% coverage, equipped with 7-strand tinned copper lead wires (two sizes smaller than conductors), and all group shields are completely isolated from each other to prevent crosstalk or capacitive coupling between adjacent wire pairs (especially for AC signals and pulse signals).

Cable overall shielding: Aluminum/polyester tape is also used to overlap and wrap to achieve 100% coverage. The drainage wire is made of 7-strand tinned copper with the same size as the conductor, which can isolate most of the static interference generated by the radiated electric field of power cables and other electrical equipment.

(3) Assembly and Sheath

Assembly method: Assemble wire pairs or three wire groups in a left twisted manner; If necessary, add flame-retardant and non absorbent fillers to ensure that the cable has a circular structure.

Sheath: Black flame retardant low-temperature Okoseal ® Materials that comply with UL 13 and UL 2250 standards; A tear rope is longitudinally laid under the sheath for easy peeling.

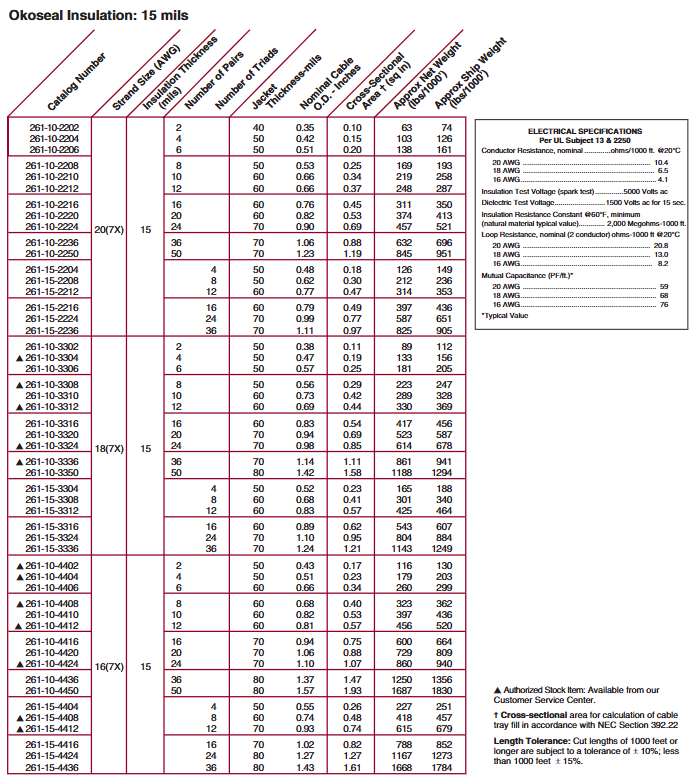

(4) Electrical performance

Specific values of electrical indicators (different specifications)

Conductor resistance (20 ° C, per 1000 feet) 20 AWG: 10.4 ohms; 18 AWG: 6.5 ohms; 16 AWG: 4.1 ohms

Insulation test voltage (spark test) 5000 volts AC

Dielectric test voltage 1500 volts AC, lasting for 15 seconds

Insulation resistance constant (60 ° F, minimum value, typical value for natural materials) 2000 megaohms -1000 feet

Loop resistance (2 conductors, 20 ° C, every 1000 feet) 20 AWG: 2.8 ohms; 18 AWG: 13.0 ohms; 16 AWG: 8.2 ohms

Mutual capacitance (typical value, picofarads per foot) 20 AWG: 59; 18 AWG:68; 16 AWG:76

(5) Classification and Compliance

Obtained UL certification, listed as ITC/PLTC cable, can be used in accordance with Article 335 and Article 722 of the 2023 National Electrical Code.

Compliant with UL 2250 (ITC standard), UL 13 (PLTC, CL2, CL3 standard); It can also be used as a power limited fire-resistant signal cable (FPL) that complies with NEC Article 760 and is certified by OSHA.

Applicable scenarios

Circuit and Power Range: Suitable for ITC unclassified or non labeled circuits (voltage up to 150 volts, current up to 5 amps, power 750 volt amperes), as well as Class 2 or Class 3 power limiting circuits.

Environmental conditions: Can be used both indoors and outdoors; Adapt to humid or dry environments (maximum working temperature of conductors is 105 ° C, low temperature installation tolerance is -40 ° C); Can be used for cable trays, cable trays, scenes supported by overhead wires, and under raised floors.

Dangerous Area: Suitable for Class 1, Zone 2, Zone 2, and Zone 2 hazardous areas.

Functional requirement: It is necessary to shield external interference to the greatest extent possible, or to shield between wire groups (especially when cables may be subjected to abnormally high current or voltage interference); The cable has a built-in communication line that can be used for voice communication during installation or instrument calibration.

Product Features

Flame retardant performance: Passed UL 13 and IEEE 383-1974 vertical tray combustion tests.

Weather and chemical resistance: resistant to sunlight and oil, with excellent weather resistance.

Anti interference capability: 100% shielding coverage, reduces electromagnetic noise pickup, and has good external noise suppression effect.

Convenience of use: Strong flexibility, easy to operate and end connect; Complete isolation of wire pairs or three wire groups, precise shielding effect.

Other supplementary information

(1) Cable tray filling calculation

The cross-sectional area of the cable needs to be calculated according to NEC Article 392.22 to determine the reasonable filling amount of the cable tray.

(2) Length tolerance

When cutting lengths of 1000 feet or more, the tolerance is ± 10%.

When the cutting length is less than 1000 feet, the tolerance is ± 15%.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands